Hanging type empty rail hinge shaft and mounting method

A suspended and empty rail technology, applied in the direction of tracks, roads, buildings, etc., can solve the problems of difficult installation, unguaranteed installation quality, and unsatisfactory stress distribution in the empty rail beam. Improve the installation environment, facilitate the realization of product functions and the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

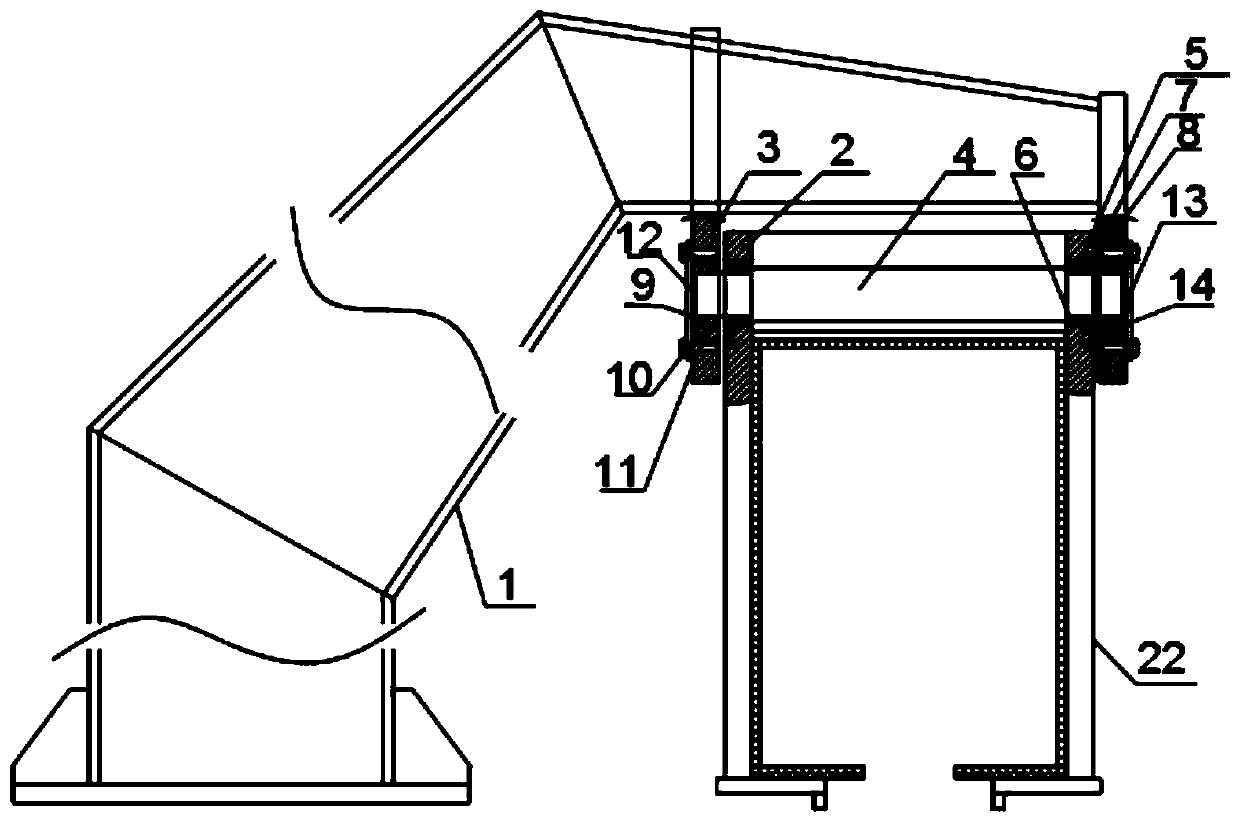

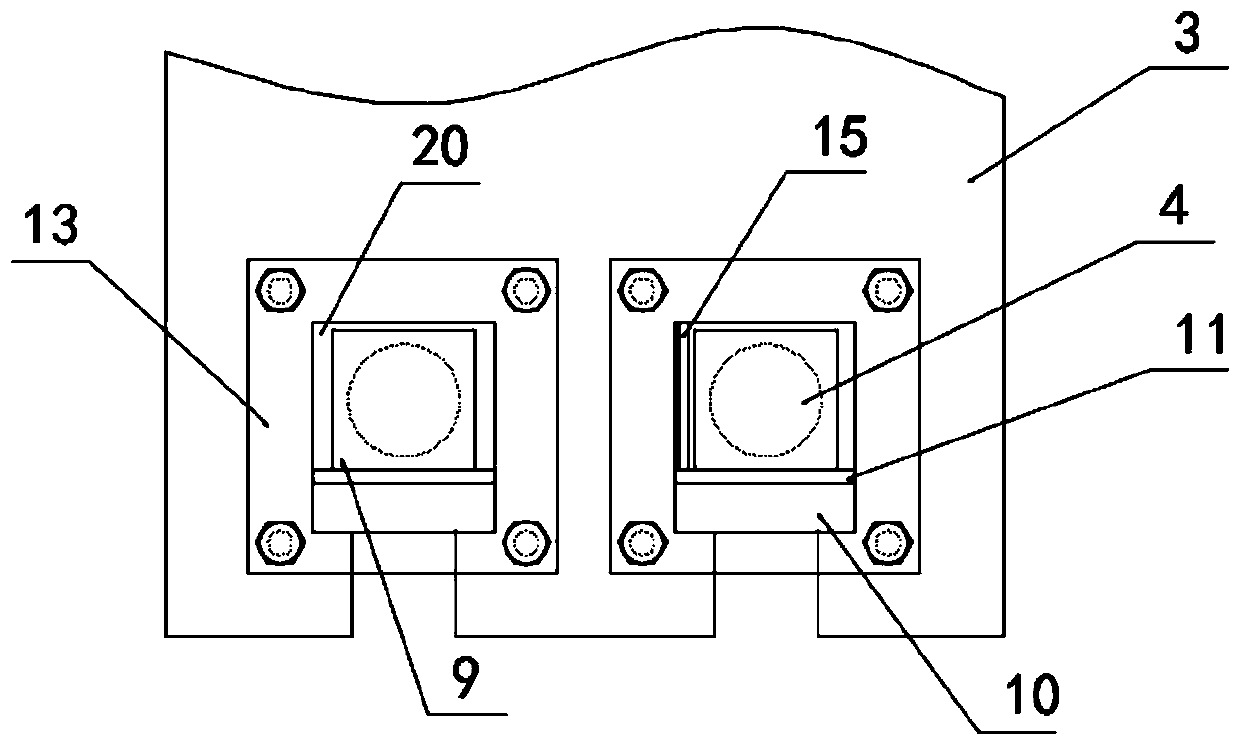

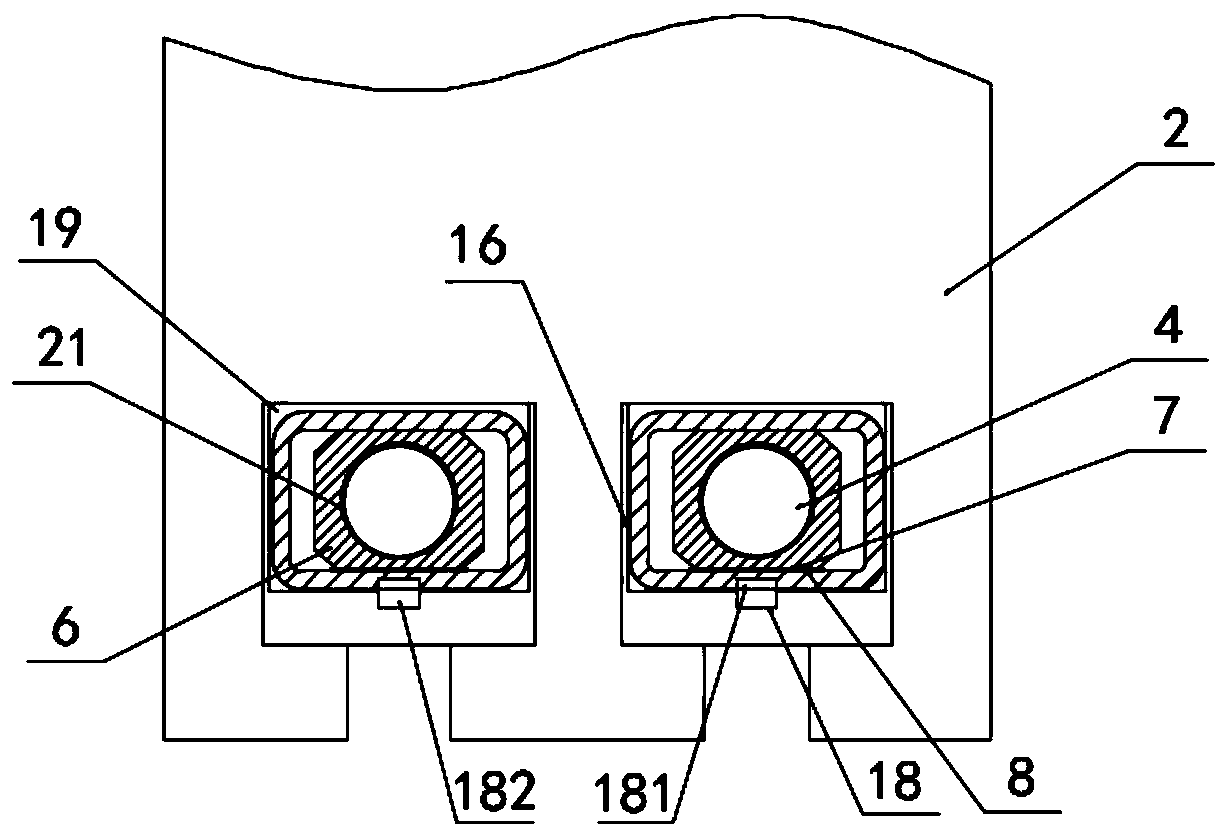

[0046] refer to Figure 1-3 , a suspended empty rail hinge shaft, comprising a pier column 1 and an empty rail beam body 22, the top of the pier column 1 is provided with a pier lug 3, and both sides of the top surface of the empty rail beam body 22 are provided with beam lugs 2, The pier lug 3 and the beam lug 2 are flexibly connected by a horizontal bearing shaft 4, the beam lug 2 is provided with a first through hole 19, the pier lug 3 is provided with a second through hole 20, and the bearing The force axis 4 is located in the first through hole 19 and the second through hole 20 at the same time.

[0047] Specifically, the pier column 1 is fixedly installed on the flat and hardened ground, and a pre-embedded base matching the pier column 1 is set on the ground in advance, and fixed bolts are used to fix the pre-embedded base, and two pier cranes are fixed on the top of the pier column 1 Ear 3, two pier lugs 3 are integrated with the pier column to enhance the firmness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com