A control method for eliminating orange peel marks on the surface of ultra-flat and ultra-thin precision strip steel for backlight panels

An ultra-thin and precise technology, applied in metal rolling, manufacturing tools, furnaces, etc., can solve the problems of poor consistency of surface crystal stress distribution, poor overall stiffness of the rolling mill, large deformation of the rolling mill stand, etc., to improve the surface orange peel problem , the effect of improving the internal stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

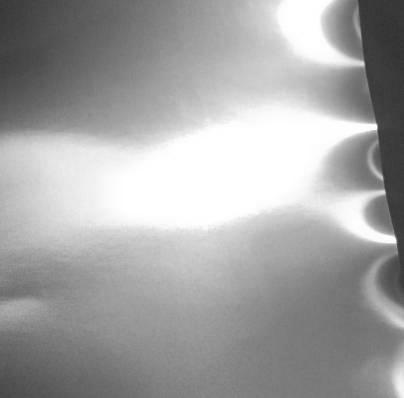

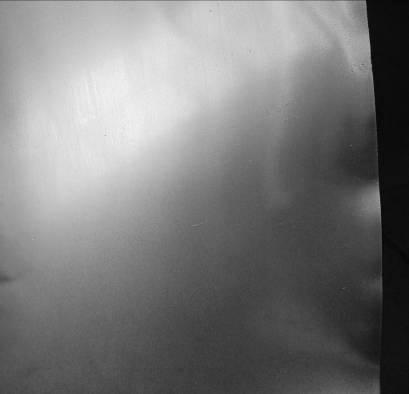

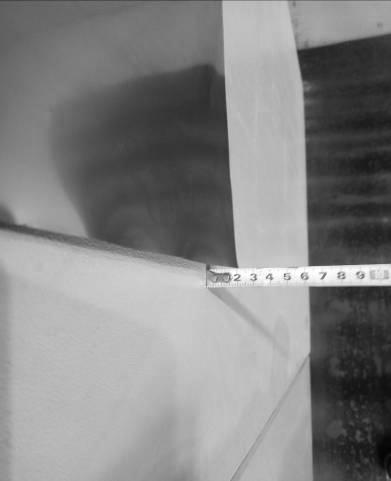

Image

Examples

Embodiment 1

[0058] In this embodiment, stainless steel with a steel grade of SUS316L, a thickness of 0.4 mm, and a width of 510 m is selected as a raw material. The production process of this embodiment is divided into two rolling passes, the thickness of the middle pass is 0.15 mm, and the thickness of the finished product is 0.05 mm.

[0059] The production process of the present embodiment is specifically as follows:

[0060] 1. In the first rolling pass, the SUS316L stainless steel with a thickness of 0.4mm is rolled to a thickness of 0.15mm. The rolling schedule is as follows:

[0061]

[0062] During the rolling process, the work roll is replaced every pass to prevent the problem of roll sticking caused by the passive film removal.

[0063] 2. The SUS316L stainless steel rolled to a thickness of 0.15mm is subjected to bright annealing treatment at a temperature of 1150°C, a speed of 27m / min, an oxygen content of <10ppm, and a dew point of less than -50°C. Sampling and inspectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com