Method for preparing high-iron bauxite pellets

A technology for high iron bauxite and pellets, applied in the field of iron making, can solve problems such as difficulty in forming a cue ball, and achieve the effects of solving the difficulty in forming a cue ball, low pulverization rate, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention does not limit the preparation method of the high-iron bauxite oxidized pellets. In other embodiments, other methods may be used to prepare the high-iron bauxite oxidized pellets required for the second-stage pelletizing process.

[0035] The high-iron bauxite particles of the present invention can also be selected from high-iron bauxite metallized pellets or high-iron bauxite raw ore in different technical solutions.

[0036] (2) Preparation of high-iron bauxite pellets

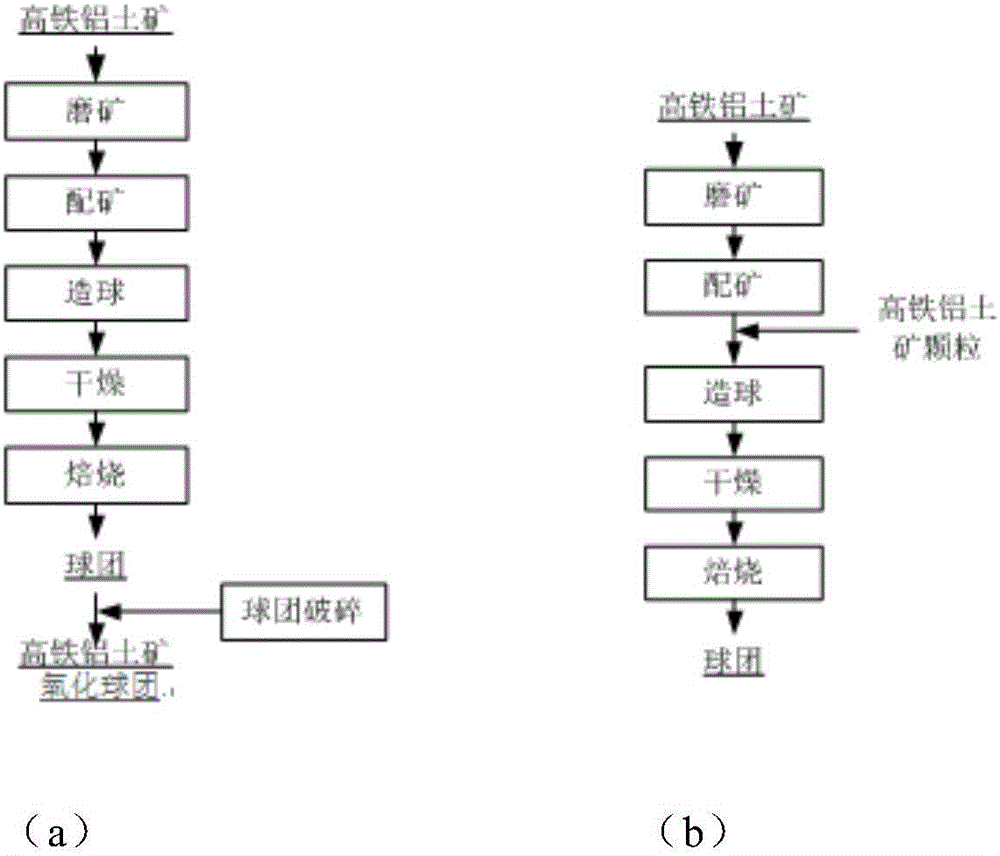

[0037] In the present invention, the high-iron bauxite particles are used as the ball-forming core in the pelletizing process of preparing high-iron bauxite pellets, which can save time in the cue ball forming stage, shorten the pelletizing process, and improve work efficiency. The flow chart of this stage is as follows figure 1 (b) shown.

[0038] Pelletizing: Place the high iron bauxite particles in the disc of the disc granulator. At the same time, the mixed material obtain...

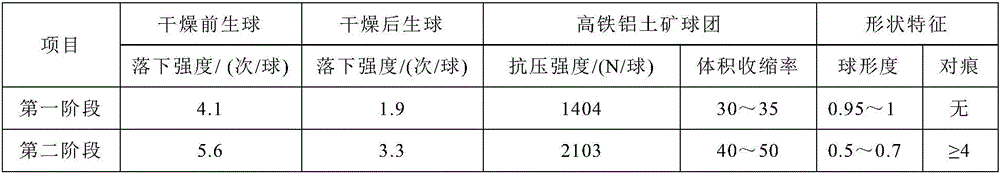

Embodiment 1

[0043] High-iron bauxite from Pingguo, Guangxi was selected, in which TFe content was 22.54wt%, Al 2 o 3 Content is 44.76wt%, SiO 2 The content is 7.32wt%. The mass percentage of the mass of the high-iron bauxite ground to a particle size of ≤74 μm to the total mass of the ore powder is 66%. Add 3wt% of calcium oxide powder, 9.5wt% of graphite powder, and 6wt% of water into the mineral powder, and mix uniformly to obtain a mixed material.

[0044] In the first stage, the inclination angle α of the disk is 54°, and the rotation speed is 20r / min. The drying temperature is 100°C, and the drying time is 2 hours. The calcination temperature is 1200°C, and the calcination time is 1h.

[0045] After the above-mentioned pellets are crushed, high-iron bauxite particles with a particle size of 4-5mm are screened out for the second stage.

[0046] In the second stage, the inclination angle α of the disk is 54°, and the rotation speed is 18r / min. The drying temperature is 100°C, an...

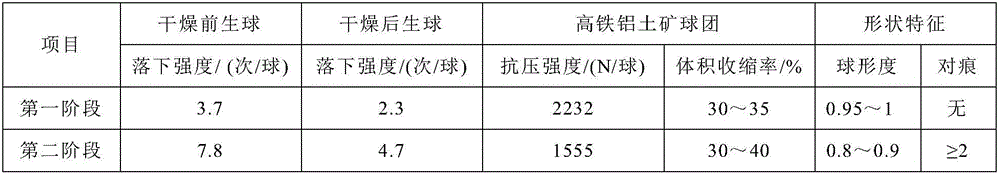

Embodiment 2

[0051] High-iron bauxite from Pingguo, Guangxi was selected, in which TFe content was 22.54wt%, Al 2 o 3 Content is 44.76wt%, SiO 2 The content is 7.32wt%. The percentage of the mass of the ore powder that grinds the high-iron bauxite to a particle size of ≤74 μm is 73% of the total mass of the ore powder. Add 5wt% of calcium oxide powder, 10.5wt% of graphite powder and 8.5wt% of water into the mineral powder, and mix uniformly to obtain a mixed material.

[0052] In the first stage, the inclination angle α of the disk is 57°, and the rotation speed is 18r / min. The drying temperature is 105°C, and the drying time is 2.5 hours. The calcination temperature is 1400°C, and the calcination time is 2h.

[0053] After the above-mentioned pellets are crushed, high-iron bauxite particles with a particle size of 3-4mm are screened out for the second stage.

[0054] In the second stage, the inclination angle α of the disk is 57°, and the rotation speed is 20r / min. The drying tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com