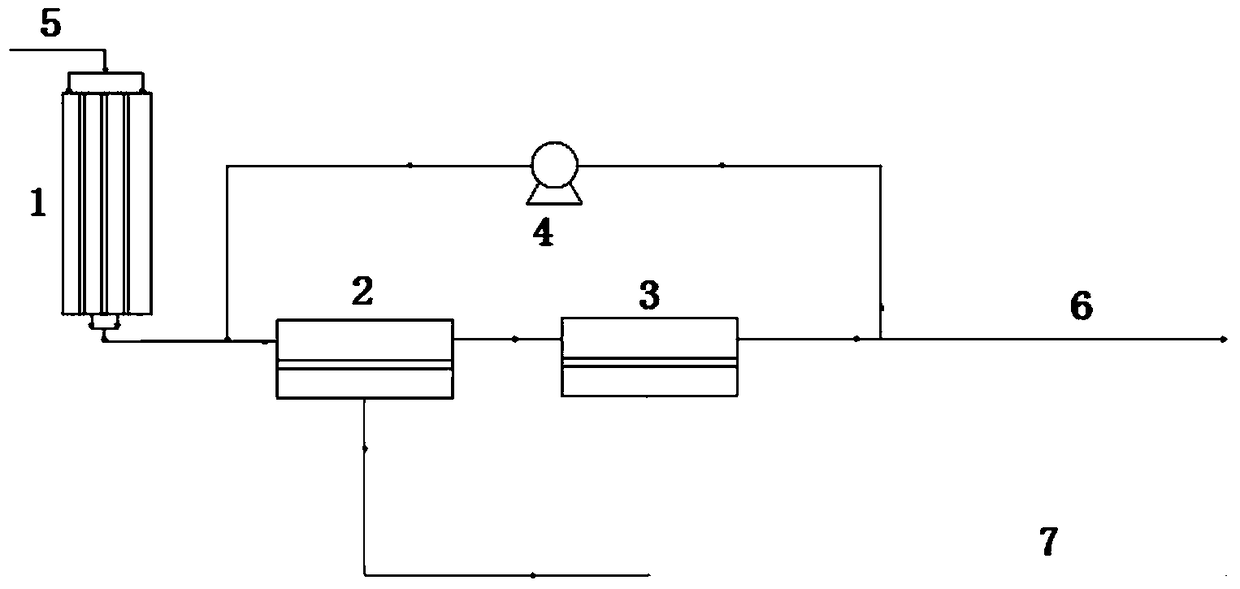

Separation system for CO2 removal from syngas/natural gas

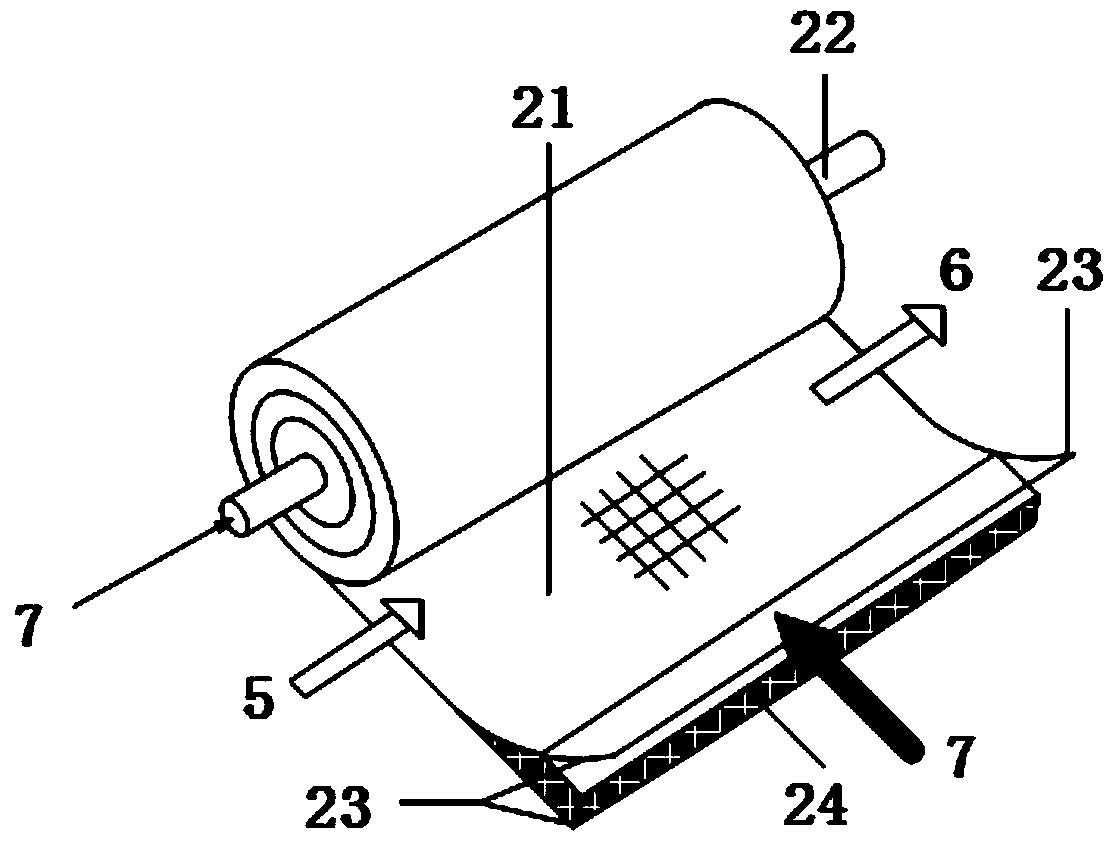

A separation system and synthesis gas technology, applied in separation methods, dispersed particle separation, combustible gas purification/reconstruction, etc., can solve the problems of poor separation effect, huge equipment, and high energy consumption, and achieve stable dust removal, long operation cycle, separation Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

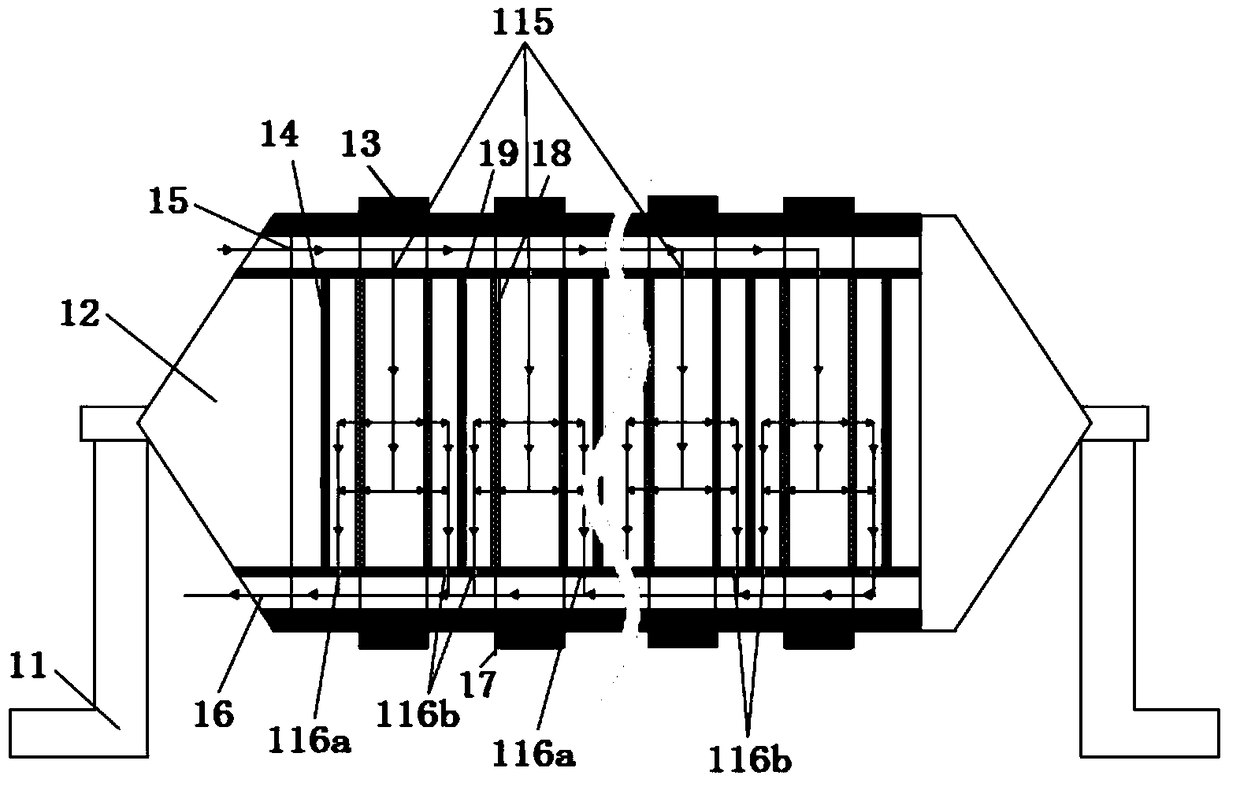

Method used

Image

Examples

Embodiment 1

[0035] Composition is 50% CH 4 , 50% CO 2 10000kmol / h contains CO 2 The natural gas contains 1% dust. After first passing through the plate and frame PTFE membrane dust collector, the dust removal efficiency can reach 98%. The gas has a two-stage membrane area of 2m 2 Under the separation effect of the membrane module, when the reflux ratio is 0, the flow rate of retentate phase 6 is 4100 kmol / h, CO 2 The composition drops to 17%. When the reflux ratio is 1, the retentate phase 6 flow rate is 2945 kmol / h, CO 2 Composition drops to 13%.

Embodiment 2

[0037] Composition is 5% CH 4 , 30%CO, 30%H 2 and 35% CO 2 The 10000kmol / h synthesis gas contains 1% dust, firstly through the plate and frame PTFE membrane dust collector, the dust removal rate is 98%, and the gas has a two-stage membrane area of 2m 2 Under the separation effect of the membrane module, when the reflux ratio is 0, the flow rate of the retentate phase 6 is 5339 kmol / h, and the gas composition is 6.34% CH 4 , 46.24% CO, 38.06% H 2 , 9.4% CO 2 , when the reflux ratio is 1, the retentate phase 6 flow rate is 4159 kmol / h, and the gas composition is 6.15% CH 4 , 50.43% CO, 36.94% H 2 , 6.46% CO 2 .

[0038] Compared with the currently used membrane separation device, the separation system of the present invention adds PTFE microporous membrane dedusting equipment at the front end of the gas separation unit, so that it can effectively avoid the pollution of a large amount of dust in natural gas and syngas to its gas separation system; At the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com