A medium-high temperature self-lubricating multi-arc ion plating multi-element gradient tool coating and its preparation method

A multi-arc ion plating and self-lubricating technology is applied to the high-temperature self-lubricating multi-element gradient tool coating, the preparation of the multi-element gradient coating, the surface coating strengthening treatment process of high-speed cutting tools, and achieves good application prospects, high hardness, improved Effect of Internal Stress Distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

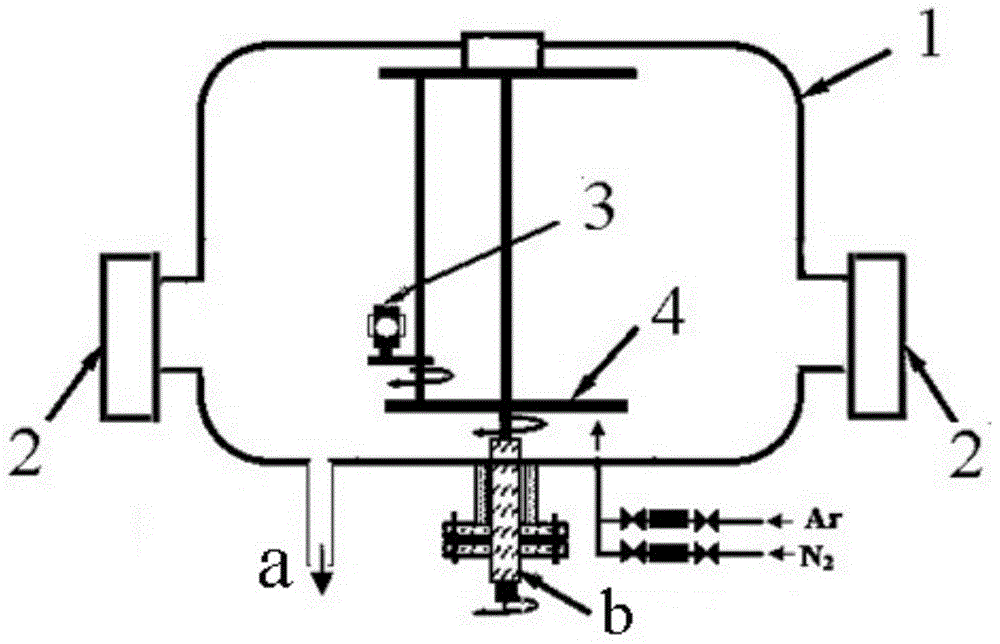

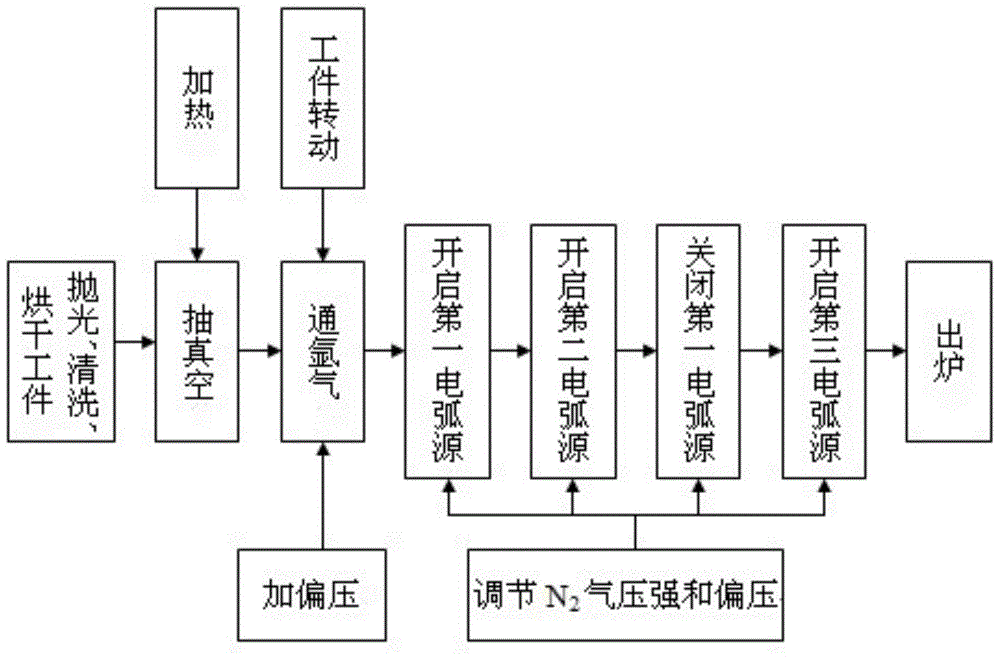

[0042] Such as figure 1 and figure 2 As shown, a method for preparing a medium-high temperature self-lubricating multi-arc ion plating multi-element gradient tool coating of the present embodiment comprises the following steps:

[0043] (1), the first arc source 2, the second arc source 2 and the third arc source 2 are respectively placed in a symmetrical position inside the vacuum chamber 1, and Ar and N 2 The gas is introduced into the vacuum chamber 1 . Among them, the target of the first arc source is made of simple Cr with a purity of 99.99%; the target of the second arc source is made of AlCr powder metallurgy, the atomic percentage of Al and Cr is 70:30, and the purity of the AlCr target is 99.99%; the third arc source is made of AlTiSi powder metallurgy, the atomic percentage of Al, Ti and Si is 60:30:10, and the purity of the AlTiSi target is 99.99%;

[0044] (2) Choose a single crystal silicon wafer as the workpiece, the size of the workpiece is 20mm×10mm×0.54mm,...

Embodiment 2

[0053] Such as figure 1 and figure 2 As shown, a method for preparing a medium-high temperature self-lubricating multi-arc ion plating multi-element gradient tool coating of the present embodiment comprises the following steps:

[0054] (1)~(6), are identical with step (1)~(6) among the embodiment 1;

[0055] (7), keep N 2 The gas partial pressure is kept constant at 3Pa, the bias voltage is reduced to 50V, the third arc source is started, and the AlCrTiSiN working layer is deposited together with the second arc source for 90 minutes;

[0056] (8), the coating process is finished, the vacuum chamber 1 is cooled to room temperature, the furnace door is opened, and the workpiece is taken out.

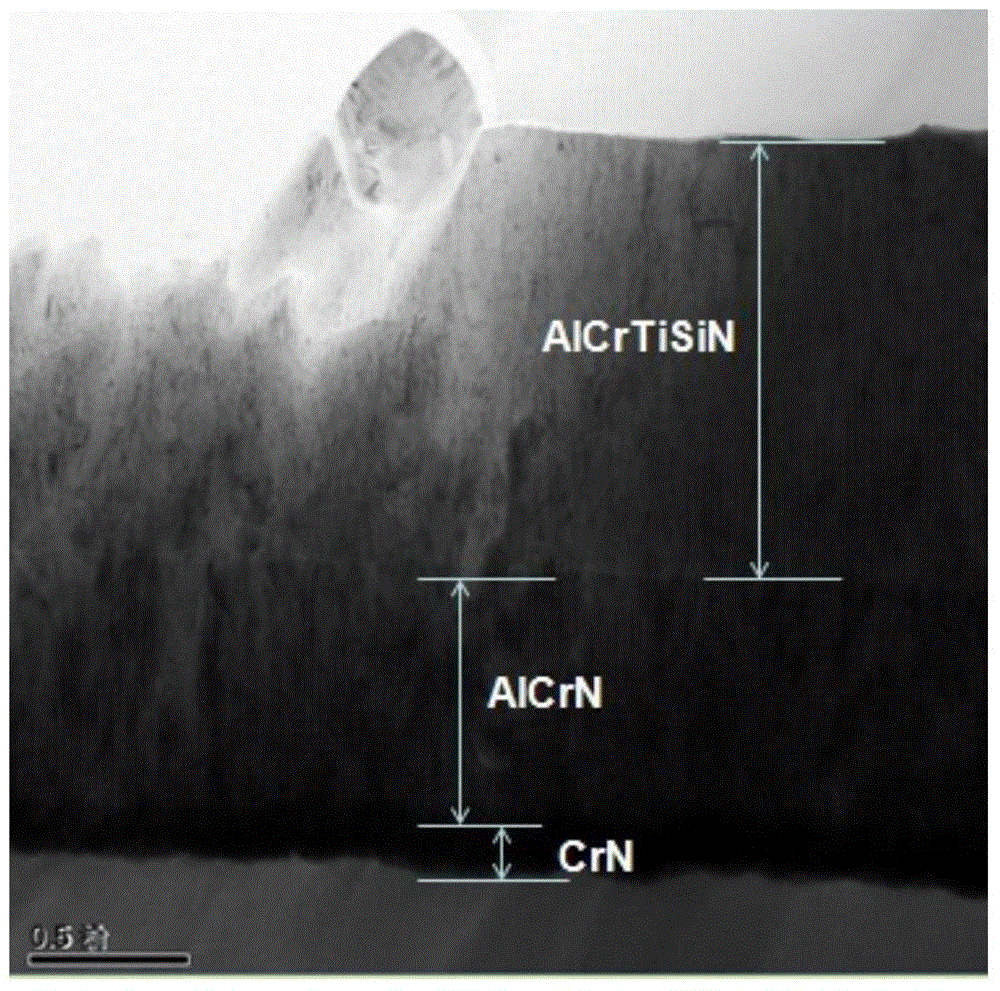

[0057] The total thickness of the prepared coating is 2.45 μm, in which the thickness of the AlCrN gradient transition layer is 0.84 μm, and the thickness of the AlCrTiSiN working layer is 1.61 μm.

Embodiment 3

[0059] Such as figure 1 and figure 2 As shown, a method for preparing a medium-high temperature self-lubricating multi-arc ion plating multi-element gradient tool coating of the present embodiment comprises the following steps:

[0060] (1)~(6), are identical with step (1) to (6) among the embodiment 1;

[0061] (7), keep N 2 The gas partial pressure is kept constant at 3Pa, the bias voltage is increased to 120V, the third arc source is started, and the AlCrTiSiN working layer is deposited together with the second arc source for 90 minutes;

[0062] (8), the coating process is finished, the vacuum chamber 1 is cooled to room temperature, the furnace door is opened, and the workpiece is taken out.

[0063] The total thickness of the prepared coating is 3.13 μm, in which the thickness of the AlCrN gradient transition layer is 1.09 μm, and the thickness of the AlCrTiSiN working layer is 2.04 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear rate | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com