Device for testing water absorption coefficient of material and method for measuring water absorption coefficient of material

A test device and coefficient technology, applied in the field of building materials research, can solve problems such as inaccurate temperature control methods and limited setting of working point, and achieve the effect of improving accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

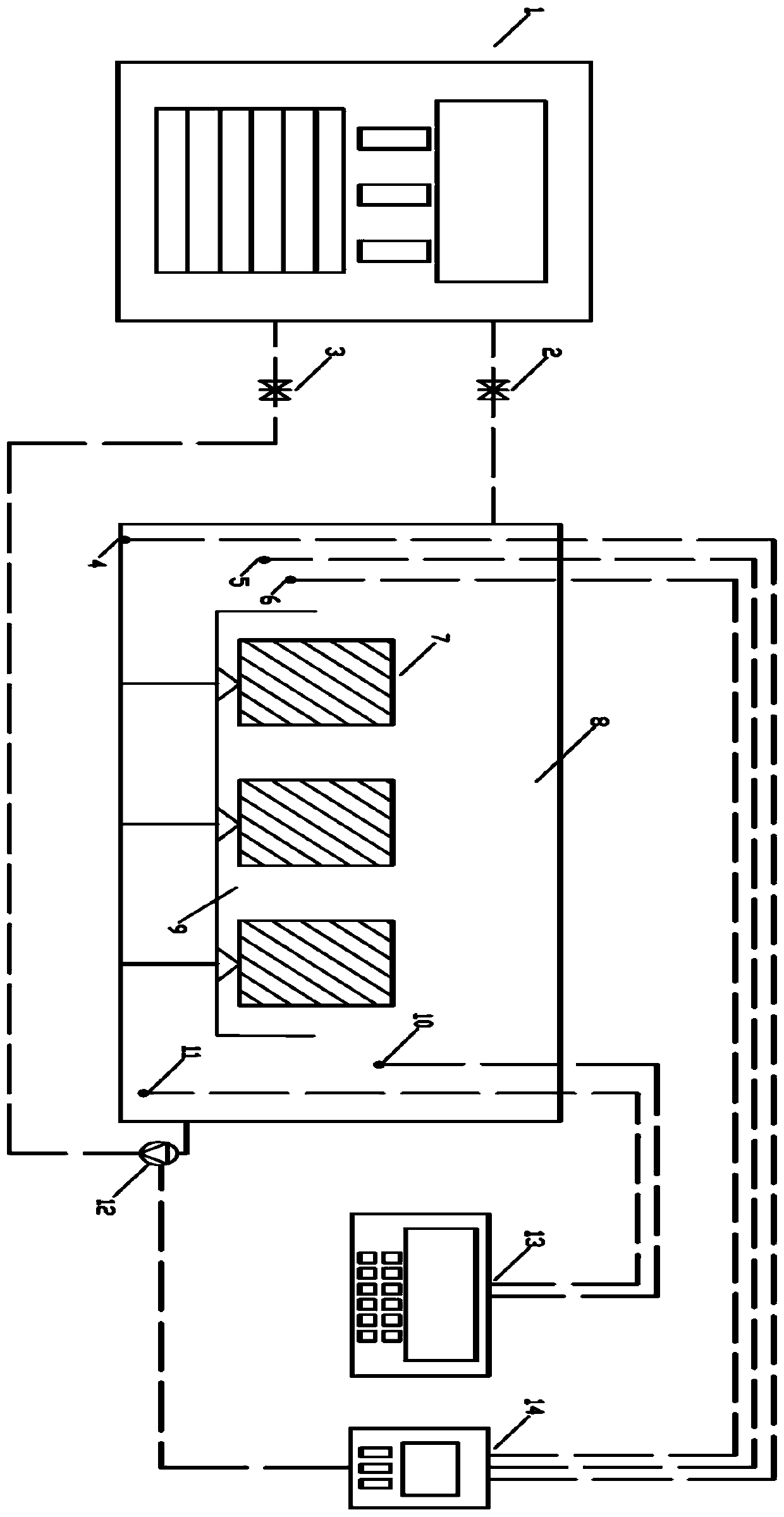

[0034] Such as figure 1 As shown, the material water absorption coefficient test device includes: a constant temperature water bath 1, a temperature control water tank 8, and a test water tank 9, wherein:

[0035] Constant temperature water bath 1, is used for providing the test water of constant temperature for temperature control tank 8, preferably, the constant temperature of setting is test temperature;

[0036] A temperature-controlled water tank 8 is connected to a constant-temperature water bath through a pipeline, and is used to store test water for controlling the test environment;

[0037] Further, the temperature control water tank forms a closed space by the tank body and the tank cover, and heat preservation treatment is carried out on the outside of the tank body and the tank cover, and the inner bottom of the temperature control water tank is provided with a bracket for supporting the test tank 9;

[0038] The test water tank 9 is placed on the support for stor...

Embodiment 2

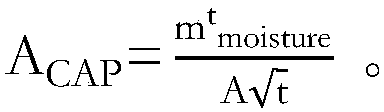

[0053] Based on the test device of the present invention, the measuring method of the test device that detects the influence of temperature on material water absorption coefficient is as follows:

[0054]S1. Connect the constant temperature water bath and the water level controller to the power supply, turn on the temperature inspection instrument, and check that the valves on the water supply and return pipelines are all open.

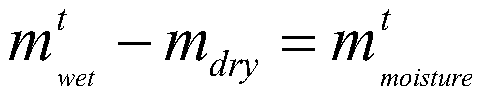

[0055] S2. Weigh the dried test piece m dry , and measure the bottom area A, put it on the pillar in the test tank, and then place the test water tank on the bracket in the temperature control tank.

[0056] Preferably, the selected sample is a building porous material.

[0057] S3. Turn on the constant temperature water bath, set the temperature of the constant temperature water bath, that is, the test temperature, continuously store water in the constant temperature water bath, and the water flows into the temperature control water tank through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com