Textile fabric thermal transfer printing bleeding test paper and making method thereof

A technology of test paper and thermal transfer printing, applied in textile testing, measuring devices, material inspection products, etc., can solve problems such as difficult selection of different textile fabrics and dyes, difficult to distinguish printing quality of trial samples and batch products, and achieve labor saving , The process is simple and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

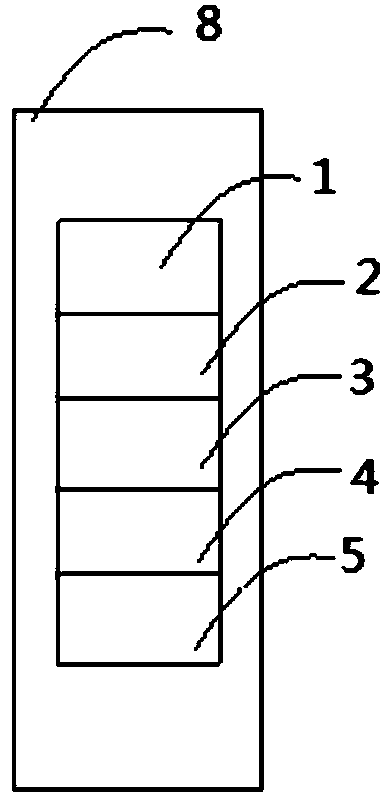

[0043] Such as figure 1 , Figure 4 As shown, a kind of woven fabric thermal transfer printing bleeding test paper, the test paper includes a base layer 8, and one side of the base layer 8 is provided with a five-level test area; wherein the first-level test area 1 is stacked sequentially from the inside to the surface. The first ink layer 11, the first cross-linked layer 12 and the first adhesive layer 13; wherein the second-level test area 2 is sequentially stacked with the second ink layer 21, the second cross-linked layer 22 and the second Adhesive layer 23; wherein the third-level test area 3 is sequentially stacked with a third ink layer 31, a third isolation layer 32, a third cross-linked layer 33 and a third adhesive layer 34 from the inside to the surface; The level test area 4 is sequentially stacked with a fourth ink layer 41, a fourth isolation layer 42, a fourth crosslinking layer 43 and a fourth adhesive layer 44 from the inside to the surface; the fifth level t...

Embodiment 2

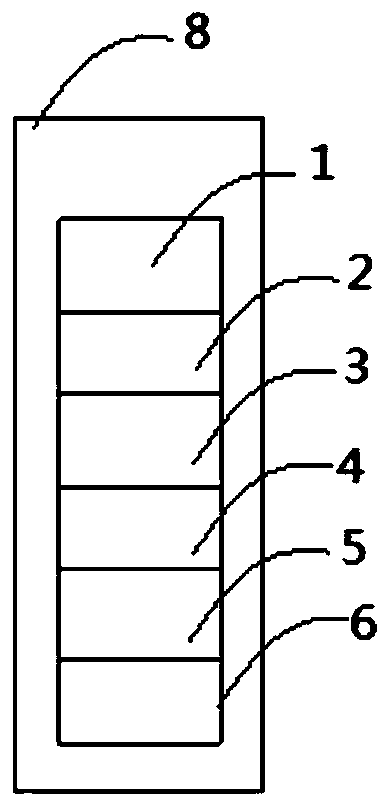

[0060] Such as figure 2 , Figure 5 As shown, a kind of textile fabric heat transfer printing bleeding test paper includes a base layer 8, and one side of the base layer 8 is provided with a six-level test area; the first-level test area 1 is sequentially laminated with a first ink layer 11 from the inside to the surface. , the first cross-linked layer 12 and the first adhesive layer 13; wherein the second-level test area 2 is sequentially stacked with a second ink layer 21, a second cross-linked layer 22 and a second adhesive layer 23 from the inside to the surface; Wherein the third-level test area 3 is sequentially stacked with a third ink layer 31, a third isolation layer 32, a third cross-linked layer 33 and a third adhesive layer 34 from the inside to the surface; wherein the fourth-level test area 4 is from The fourth ink layer 41, the fourth isolation layer 42, the fourth cross-linking layer 43 and the fourth adhesive layer 44 are laminated sequentially from the insi...

Embodiment 3

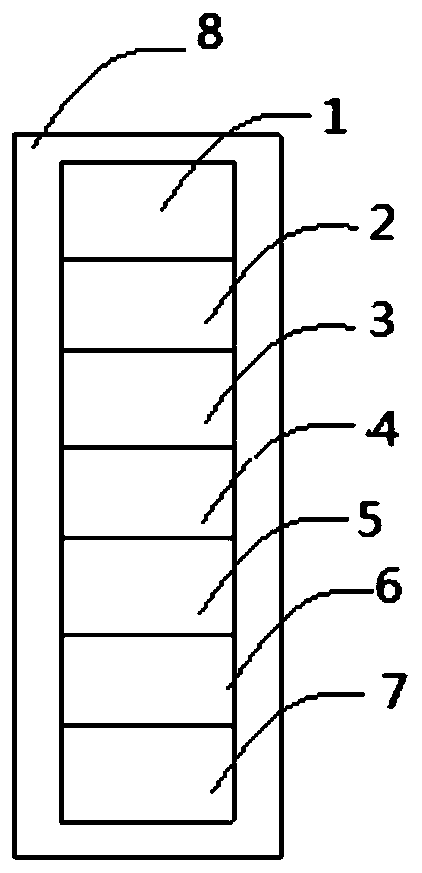

[0077] Such as image 3 , Figure 6 As shown, a kind of woven fabric thermal transfer printing bleeding test paper includes a base layer 8, and one side of the base layer 8 is provided with a seven-level test area; the first-level test area 1 is sequentially laminated with a first ink layer 11 from the inside to the surface. , the first cross-linked layer 12 and the first adhesive layer 13; wherein the second-level test area 2 is sequentially stacked with a second ink layer 21, a second cross-linked layer 22 and a second adhesive layer 23 from the inside to the surface; Wherein the third-level test area 3 is sequentially stacked with a third ink layer 31, a third isolation layer 32, a third cross-linked layer 33 and a third adhesive layer 34 from the inside to the surface; wherein the fourth-level test area 4 is from The fourth ink layer 41, the fourth isolation layer 42, the fourth cross-linking layer 43 and the fourth adhesive layer 44 are laminated sequentially from the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com