Revit-based aluminum template design method and system

A design method and design system technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as low efficiency, high design difficulty, difficult editing and adjustment of schemes, etc., to improve efficiency and automation, and facilitate modification and adjustment , the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

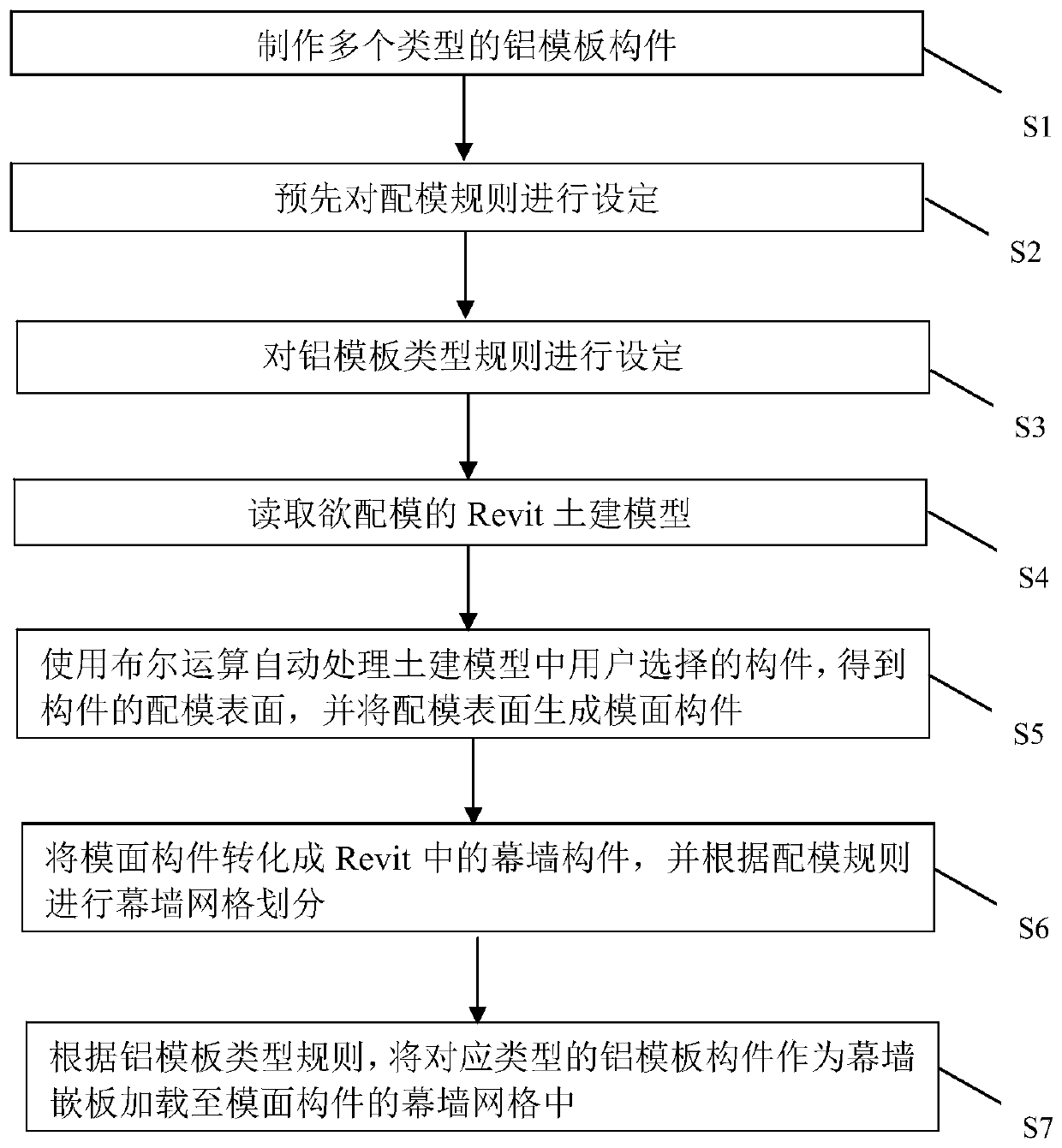

[0062] Such as figure 1 As shown, this embodiment 1 discloses a Revit-based aluminum formwork design method, comprising the following steps:

[0063] S1, making multiple types of aluminum formwork components, and setting the parameters of each type of aluminum formwork component, the parameters include the geometric style, geometric parameters and hole position parameters of the aluminum formwork component;

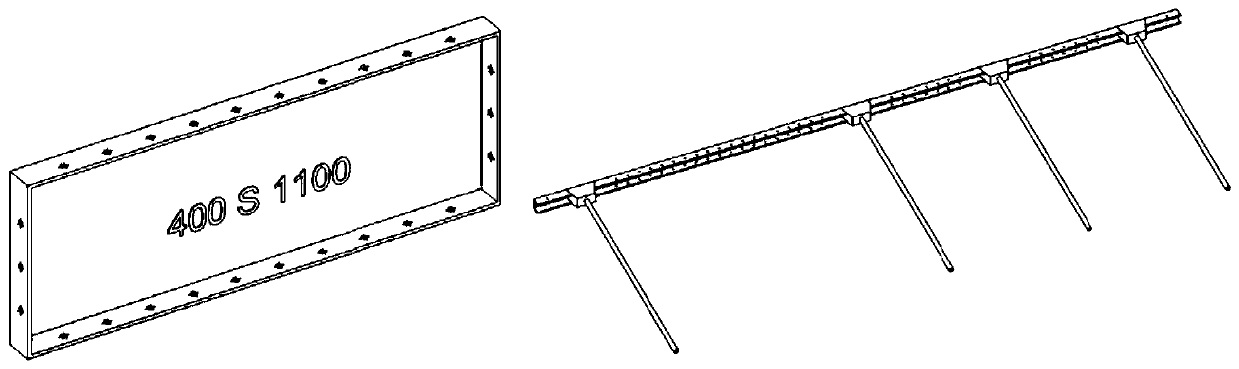

[0064] Specifically, multiple types of aluminum formwork components can be designed as component families in Revit. According to the actual structure of the aluminum formwork, it can be designed as follows figure 2 The panel family shown in is used as the basic component library of the system. In actual operation, due to the various styles of aluminum formwork, parameters such as the geometric style of aluminum formwork components can also be adjusted according to actual conditions.

[0065] S2. Set the mold matching rules in advance; the mold matching rules are used t...

Embodiment 2

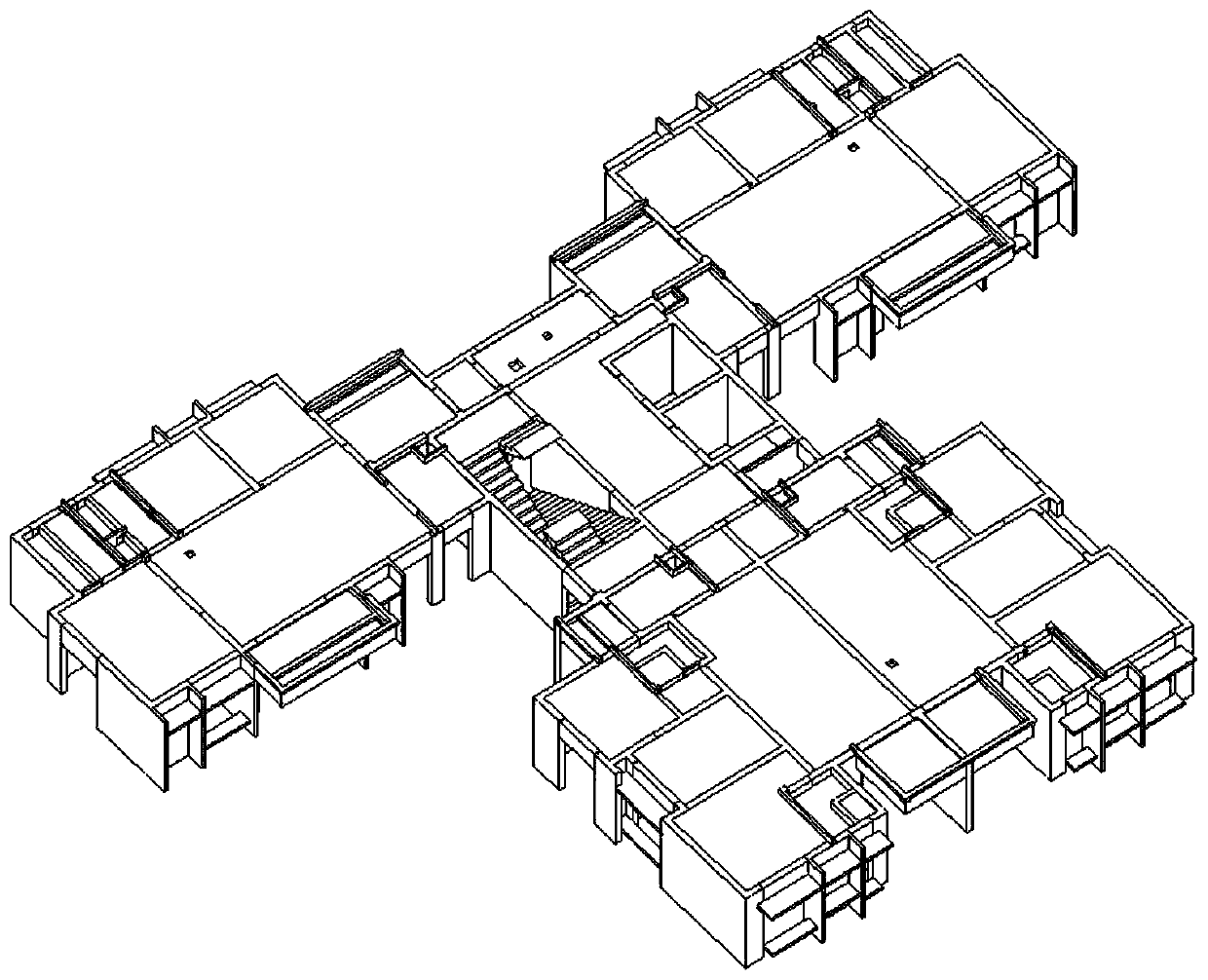

[0090] Such as Figure 10 As shown, this embodiment corresponds to the aluminum formwork design method in Example 1, and discloses a Revit-based aluminum formwork design system, including:

[0091] Modeling reading module 1, used to read the Revit civil model to be matched;

[0092] Specifically, the Revit civil model can be designed by the designer according to the actual construction requirements, or the civil model provided by the customer can be directly imported into the modeling reading module 1 .

[0093] The mold surface generation module 2 is used to automatically process the components selected by the user in the civil engineering model using Boolean operations, obtain the mold matching surface of the component, and generate the mold surface component from the mold matching surface; specifically, the mold surface generation module 2 includes:

[0094] The component union unit 21 is used to obtain the components selected by the user in the civil engineering model, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com