Secondary line manufacturing system and method for electrical cabinet

A production method and secondary line technology, applied in the direction of electrical components, circuits, circuit/collector components, etc., can solve problems such as low work efficiency, error-prone, messy work site, etc., to achieve slow solution efficiency and reduce error rate , easy-to-understand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

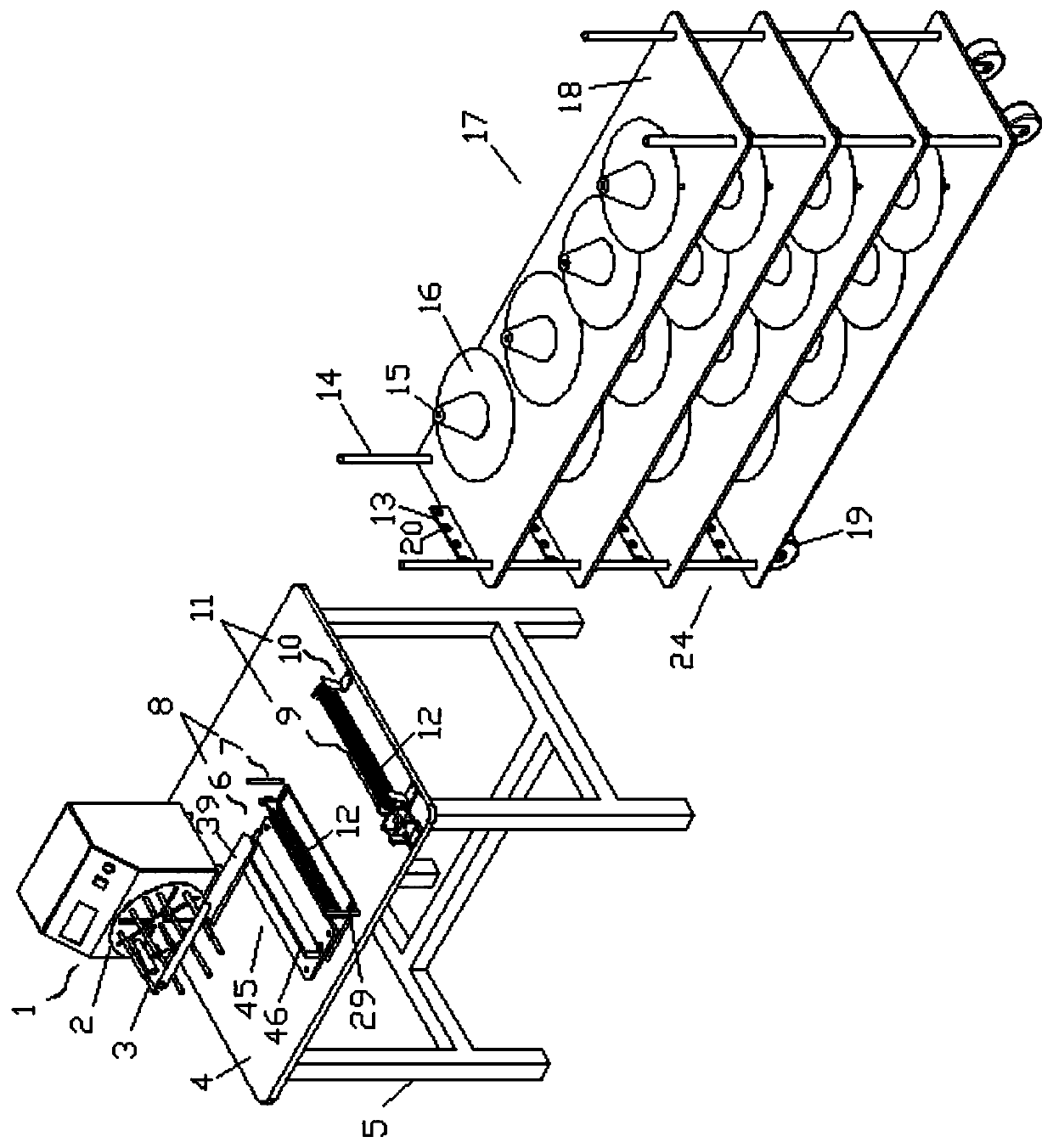

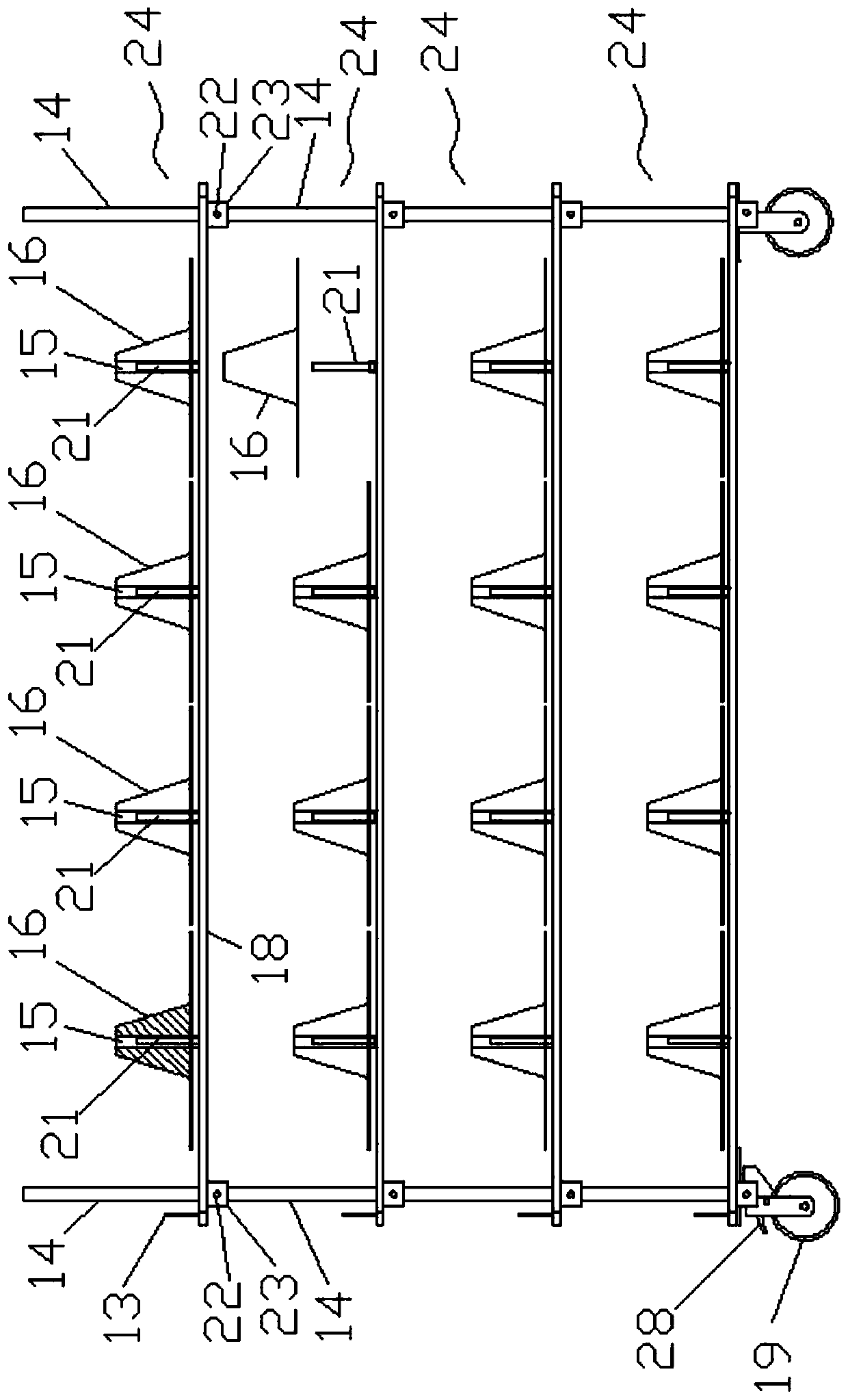

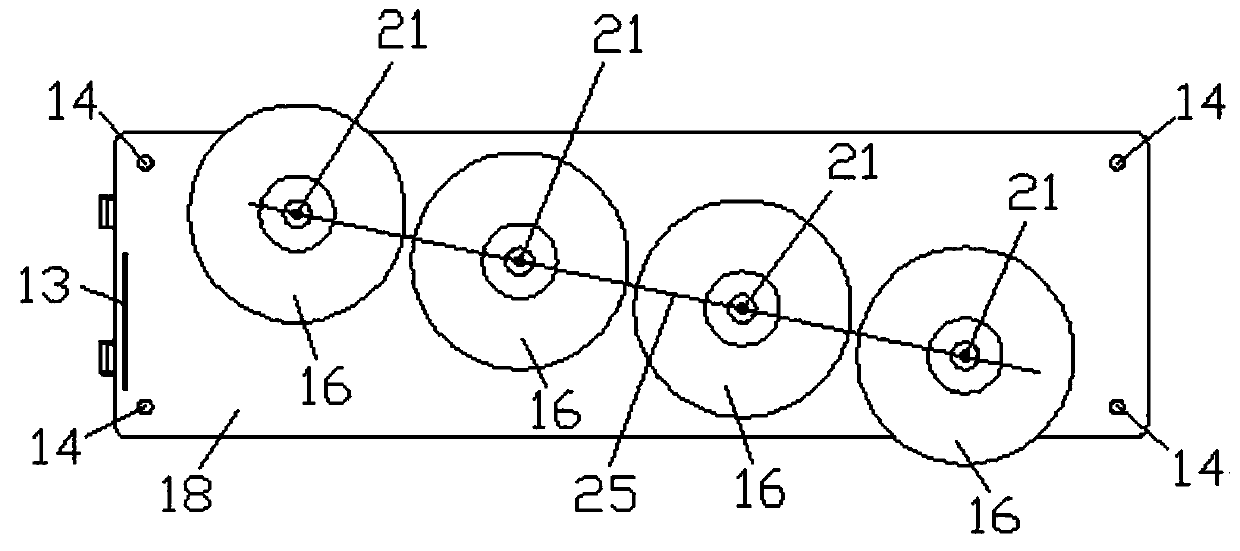

[0057] Depend on Figure 1-Figure 12 A kind of electrical cabinet secondary wire production system shown, comprises wire rack 17 and workbench 4, and workbench 4 and wire rack 17 are arranged at intervals left and right.

[0058] Several horizontal laminates 18 are sequentially arranged at intervals from top to bottom on the wire frame 17. Specifically, the wire frame 17 includes several laminate units 24 arranged sequentially from top to bottom, and the laminate units 24 include the layer Plate 18 and four pillars 14 are fixed on the upper side of the laminate 18, the laminate 18 is a rectangular plate extending vertically and horizontally on the left and right, and the four pillars 14 are respectively fixed at the four corners of the laminate 18, and the laminate 18 The bottom surface is provided with four protrusions 23, and each protrusion 23 is provided with a groove with a notch downward. In the upper and lower adjacent two-layer board units 24: the tops of the four pill...

Embodiment 2

[0066] Depend on Figure 13-Figure 30 As shown, the method for manufacturing the secondary wire of the electrical cabinet realized by using the secondary wire manufacturing system of the electrical cabinet described in Embodiment 1 includes the following steps:

[0067] (1) At least one wire reel 16 is wound with wires on the outer ring. The wires here are the secondary wires used to form the secondary wire harness. Since the secondary wires are bought, they are wound into rolls, so the secondary wires are directly placed outside the wire reel. Only one wire is wound on one wire reel. In this embodiment, several wire reels on the wire rack 17 are wound with wires, and the several wires wound on several wire reels 16 are pulled to the left and made They pass through several wire holes 20 respectively. The number of wires in a bundle of secondary wire harnesses is determined by the number of tooling. The wires on the upper wire reel on any layer pass through the wire holes on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap