Parallel LED current-sharing circuit of motor driving system

An LED circuit and motor drive technology, applied in control systems, electric light sources, electrical components, etc., can solve problems such as accelerated LED aging or damage, and achieve the effects of improving reliability, improving current sharing, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

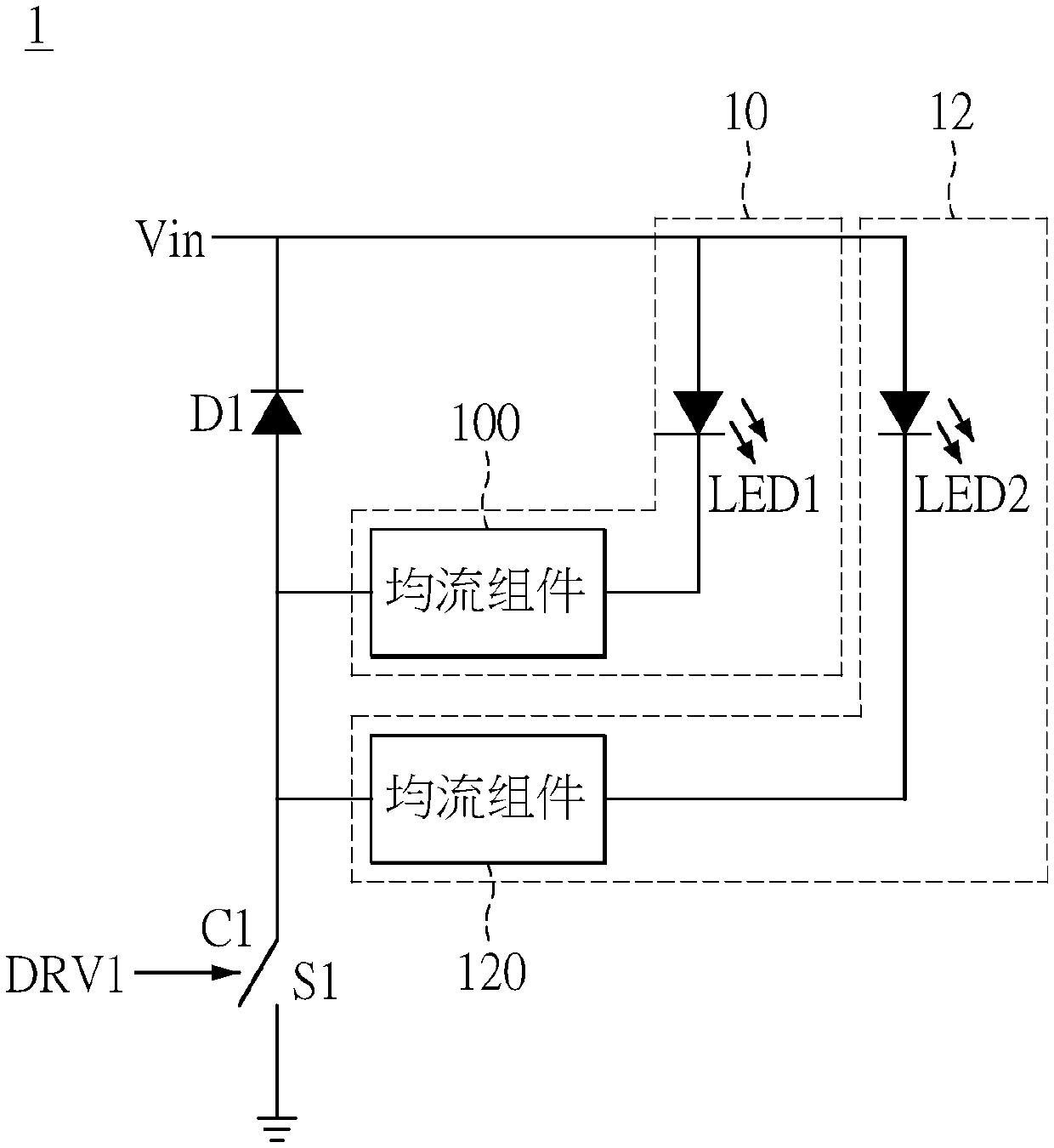

[0027] see figure 1 as shown, figure 1 It is a circuit layout diagram of a parallel LED current sharing circuit according to the first embodiment of the present invention. As can be seen from the above figures, the first embodiment of the present invention provides a parallel LED current equalizing circuit 1 , including LED circuits 10 and 12 connected in parallel, an input power source Vin, a switch component S1 and a diode D1. The LED circuit 10 includes a light emitting diode LED1 and a current equalizing component 100 connected in series with the light emitting diode LED1 , and the LED circuit 12 includes a light emitting diode LED2 and a current balancing component 120 connected in series with the light emitting diode LED2 . One end of the current equalizing component 100 is connected to the negative pole of the light emitting diode LED1, and one end of the current equalizing component 120 is connected to the negative pole of the light emitting diode LED2. The input pow...

no. 2 example

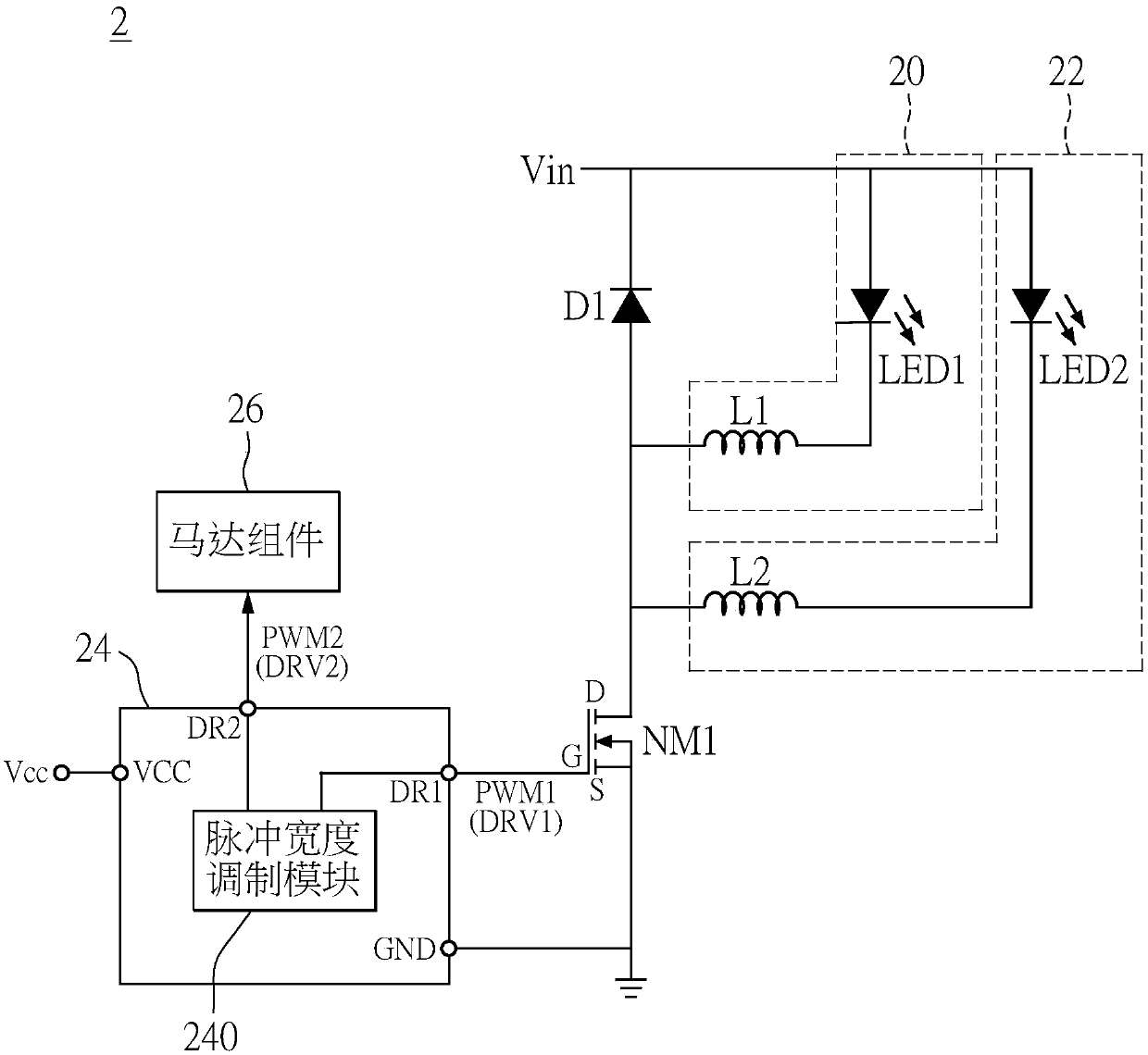

[0038] Please refer to figure 2 , figure 2 It is a circuit layout diagram of the parallel LED current sharing circuit of the motor driving system according to the second embodiment of the present invention. In this embodiment, similar to the first embodiment, similar component symbols represent similar components, and details are not repeated here.

[0039] As shown in the figure, the second embodiment of the present invention provides a parallel LED current sharing circuit 2 for a motor drive system, including LED circuits 20 and 22 connected in parallel, an input power supply Vin, an N-type MOS field effect transistor NM1, a diode D1 and Motor drive circuit 24.

[0040] The LED circuit 20 includes a light emitting diode LED1 and an inductor L1 connected in series with the light emitting diode LED1 , and the LED circuit 22 includes a light emitting diode LED2 and an inductor L2 connected in series with the light emitting diode LED2 . One ends of the inductors L1 and L2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com