Display panel and display device

A display panel and substrate technology, applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems of low light transmission efficiency and low color gamut of display devices, improve transmittance and backlight utilization, reduce costs, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

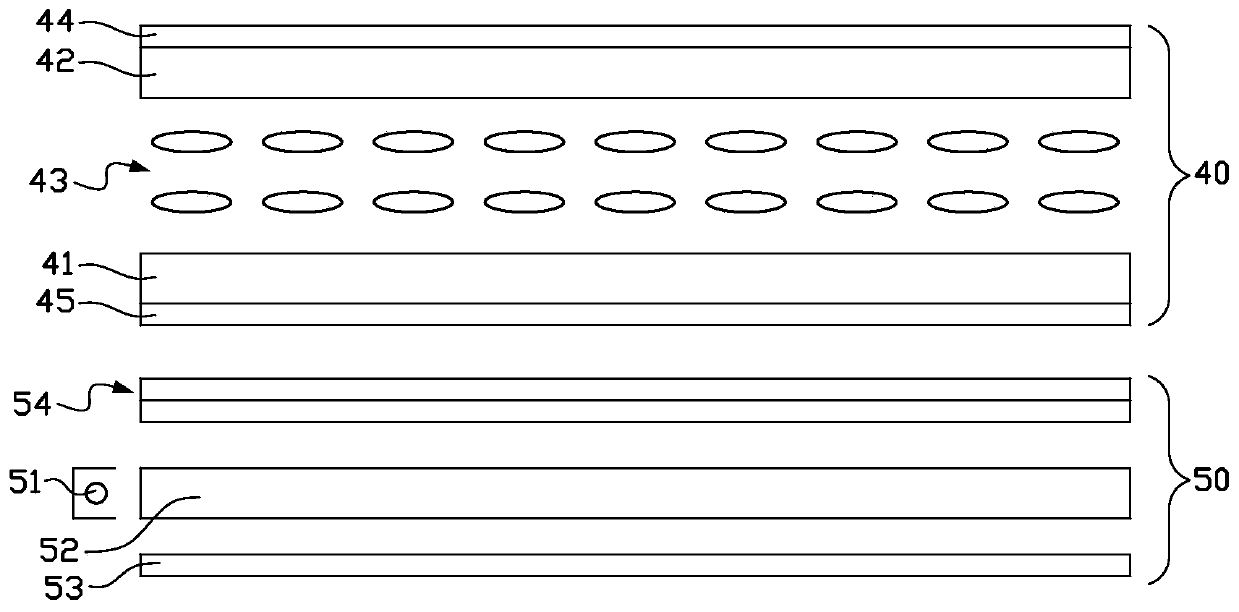

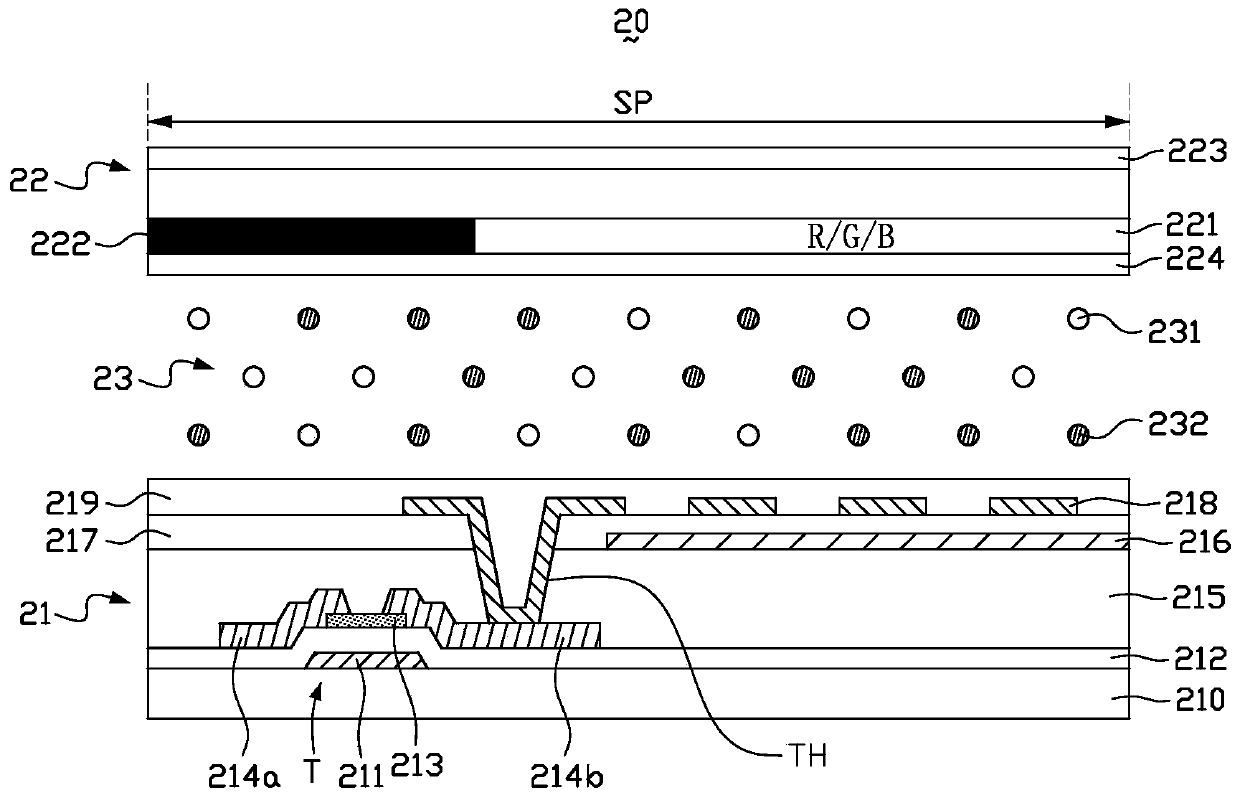

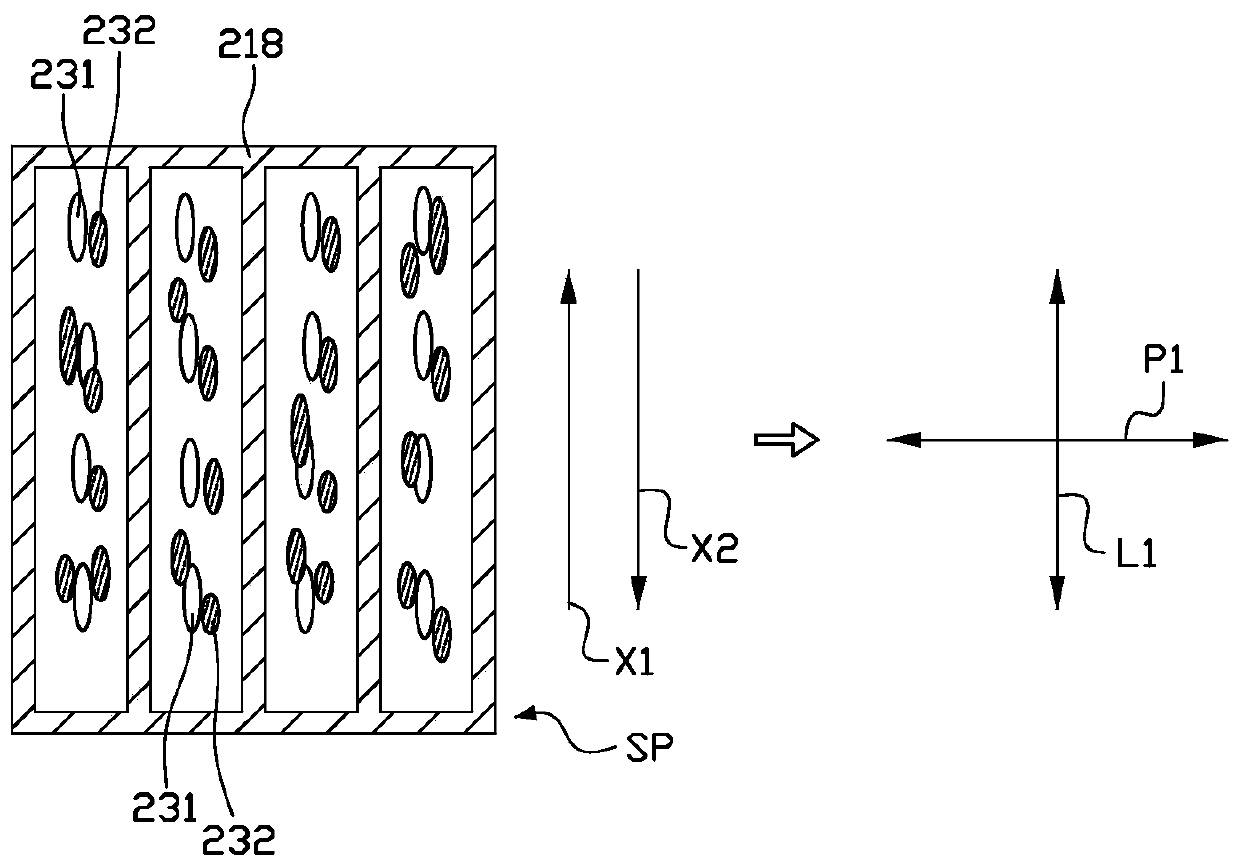

[0032] Please refer Figure 2 to Figure 5 The first embodiment of the present invention provides a display panel 20 including a first substrate 21, a second substrate 22 disposed opposite to the first substrate 21, and a liquid crystal layer 23 located between the first substrate 21 and the second substrate 22.

[0033] The first substrate 21 may be a thin film transistor array substrate. The first substrate 21 is provided with multiple scan lines (not shown), multiple data lines (not shown), and multiple One thin film transistor T, a common electrode 216 and a plurality of pixel electrodes 218. The plurality of scan lines and the plurality of data lines are insulated and crossed to define a plurality of pixel regions SP arranged in an array ( Figure 2 to Figure 5 Indicates one of the pixel regions SP). Each pixel region SP is provided with a thin film transistor T and a pixel electrode 218, and the pixel electrode 218 is connected to a corresponding scan line and a data line th...

no. 2 example

[0055] Please refer Figure 6 to Figure 9 The second embodiment of the present invention provides a display panel 20 including a first substrate 21, a second substrate 22 disposed opposite to the first substrate 21, and a liquid crystal layer 23 located between the first substrate 21 and the second substrate 22. The first substrate 21 may be a thin film transistor array substrate, and the second substrate 22 may be a color filter substrate.

[0056] The main difference between this embodiment and the above-mentioned first embodiment is that the pixel electrode 218 and the common electrode 216 are respectively located on different substrates. The pixel electrode 218 is formed on the first substrate 21 and the common electrode 216 is formed on the second substrate 22. For other structures of this embodiment, reference may be made to the above-mentioned first embodiment, which will not be repeated here.

[0057] Such as Image 6 with Figure 7 As shown, when no voltage is applied bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com