Processing method for preheating section spraying box and final cooling section spraying box

A processing method and technology of preheating section, applied in the field of processing and manufacturing of spray box, can solve the problems of nozzle flatness and welding deformation being difficult to control, inner welding seam not being able to be welded, and the height of spray box being low, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be explained below based on the embodiments shown in the drawings. The embodiment disclosed this time can be considered to be an illustration in all aspects and not restrictive. The scope of the present invention is not limited by the description of the following embodiments, but is shown only by the scope of the claims, and includes the same meaning and all modifications within the scope of the claims.

[0033] The processing method of the spray box of the preheating section and the final cooling section of the present invention will be described below with reference to specific embodiments.

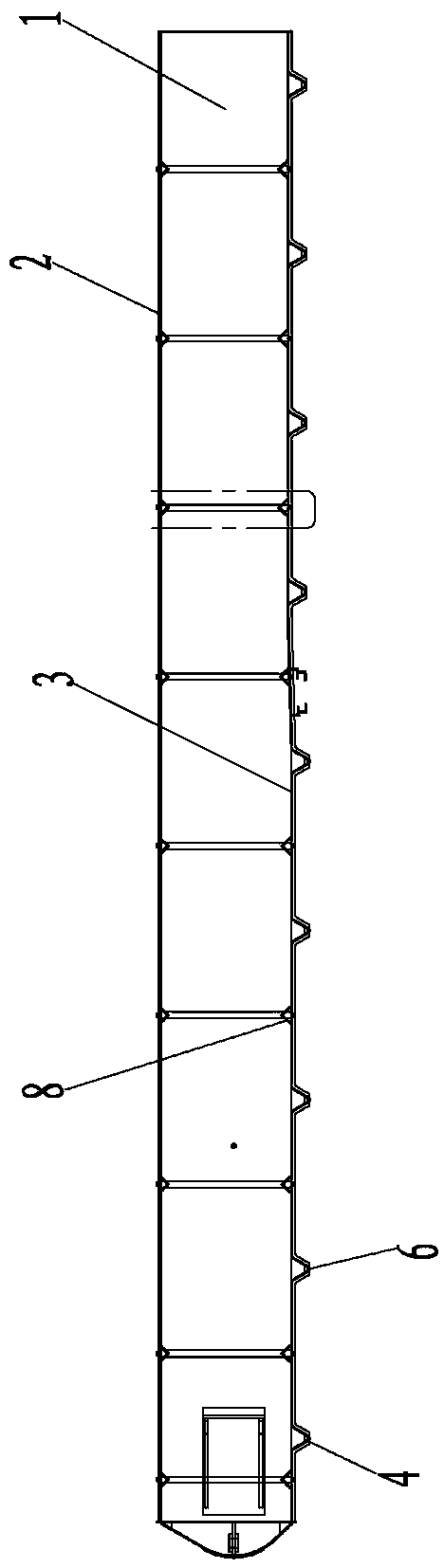

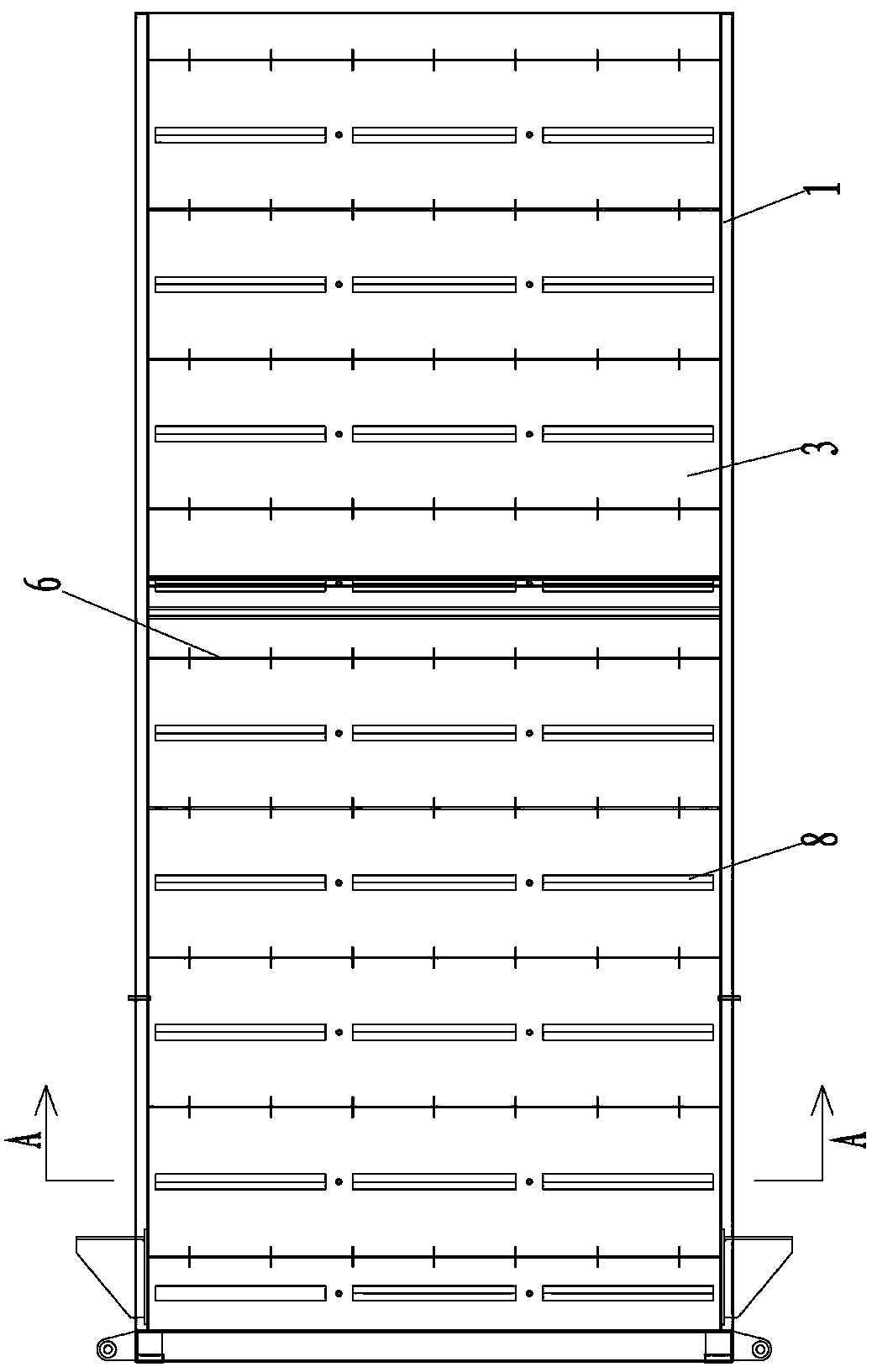

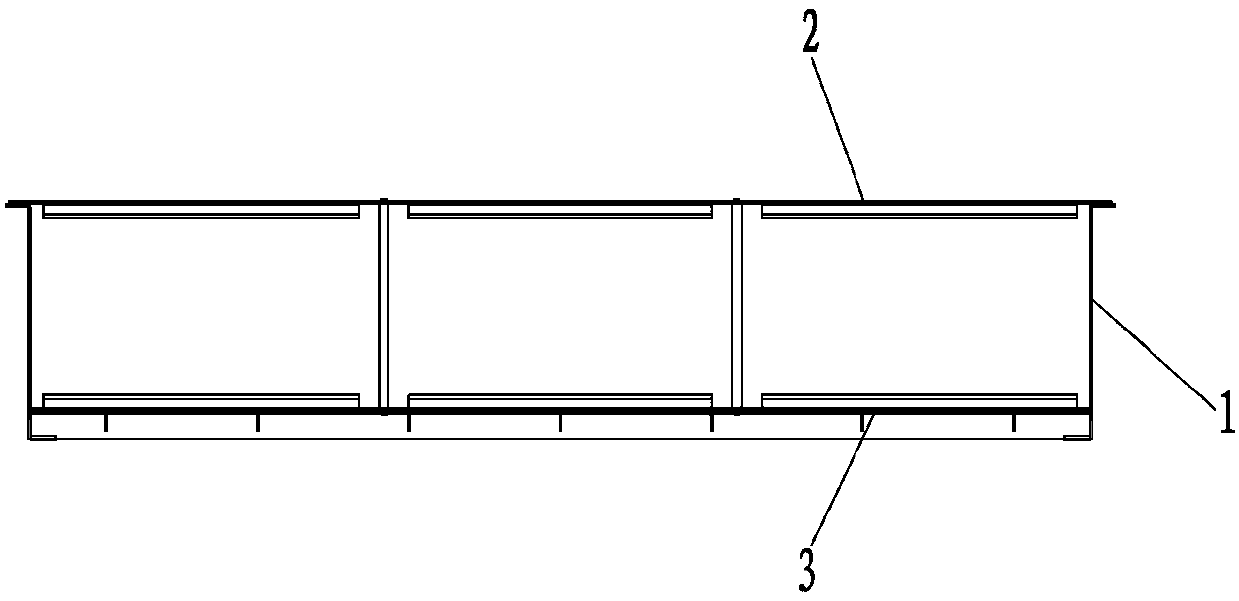

[0034] reference Figure 1 to Figure 3 As shown, the method for processing the spray box in the preheating section of the annealing furnace of the cold rolling vertical continuous rolling line and the galvanizing line of the present invention includes the following steps:

[0035] (1) Choose the material. Because the inherent stress of the original flat plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com