Vertical high-precision powder dosing device with three-axis movement

A quantitative feeding device, vertical technology, applied in the field of three-axis moving vertical powder high-precision quantitative feeding device, can solve the problems of poor stability, easy interference, etc., to achieve good sealing, smooth surface, simple and fast action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

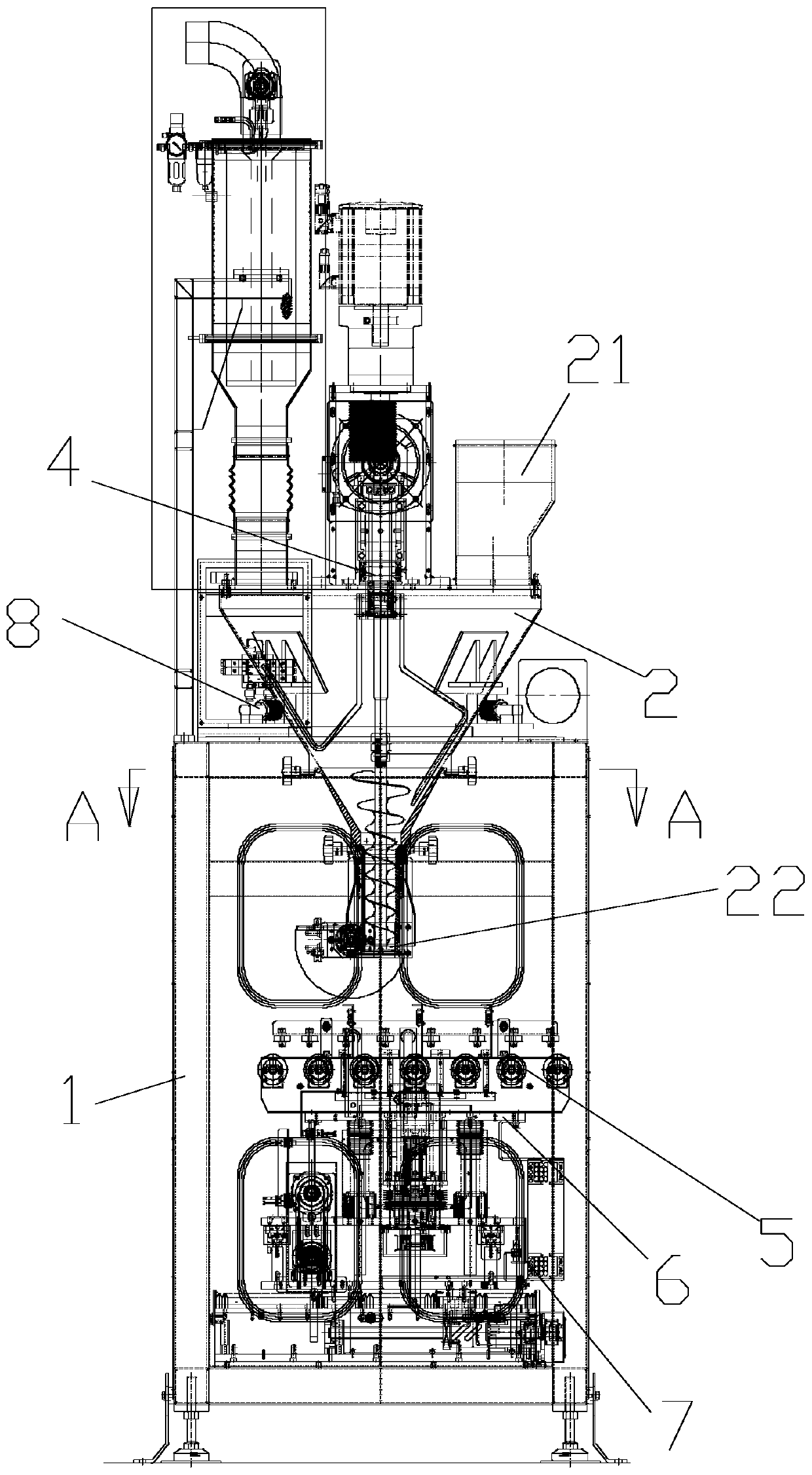

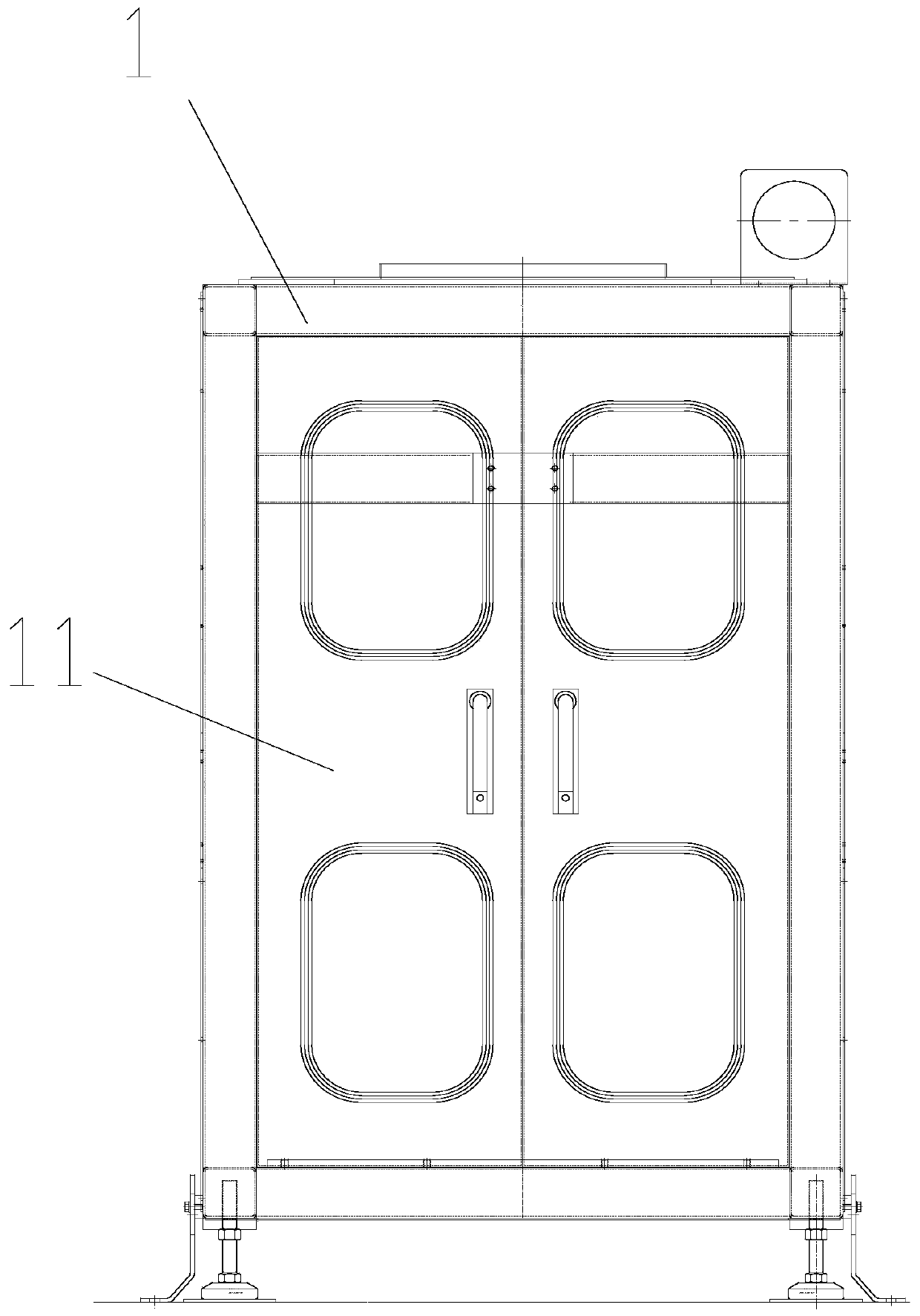

[0038] like Figure 1~2 , a three-axis mobile vertical powder high-precision quantitative feeding device, including a frame 1, a storage bin 2 is arranged above the frame 1, a feeding port 21 is arranged on the top of the storage bin 2, and a feeding port 21 is arranged at the bottom of the storage bin 2 Outlet 22, the frame 1 is provided with a door switch mechanism 3 for closing or opening the outlet 22 near the outlet 22, and the storage bin 2 is provided with an unloading unit 4 for outputting materials.

[0039] Below the storage bin 2 there is a conveying unit 5 for transporting the container to the discharge port 22 of the storage bin 2, the frame 1 is provided with a conveying platform 6 for carrying the conveying unit 5, and below the conveying unit 5 is provided with a The entire conveying unit 5 is lifted from the conveying platform 6 and moves the mobile jacking unit 7 .

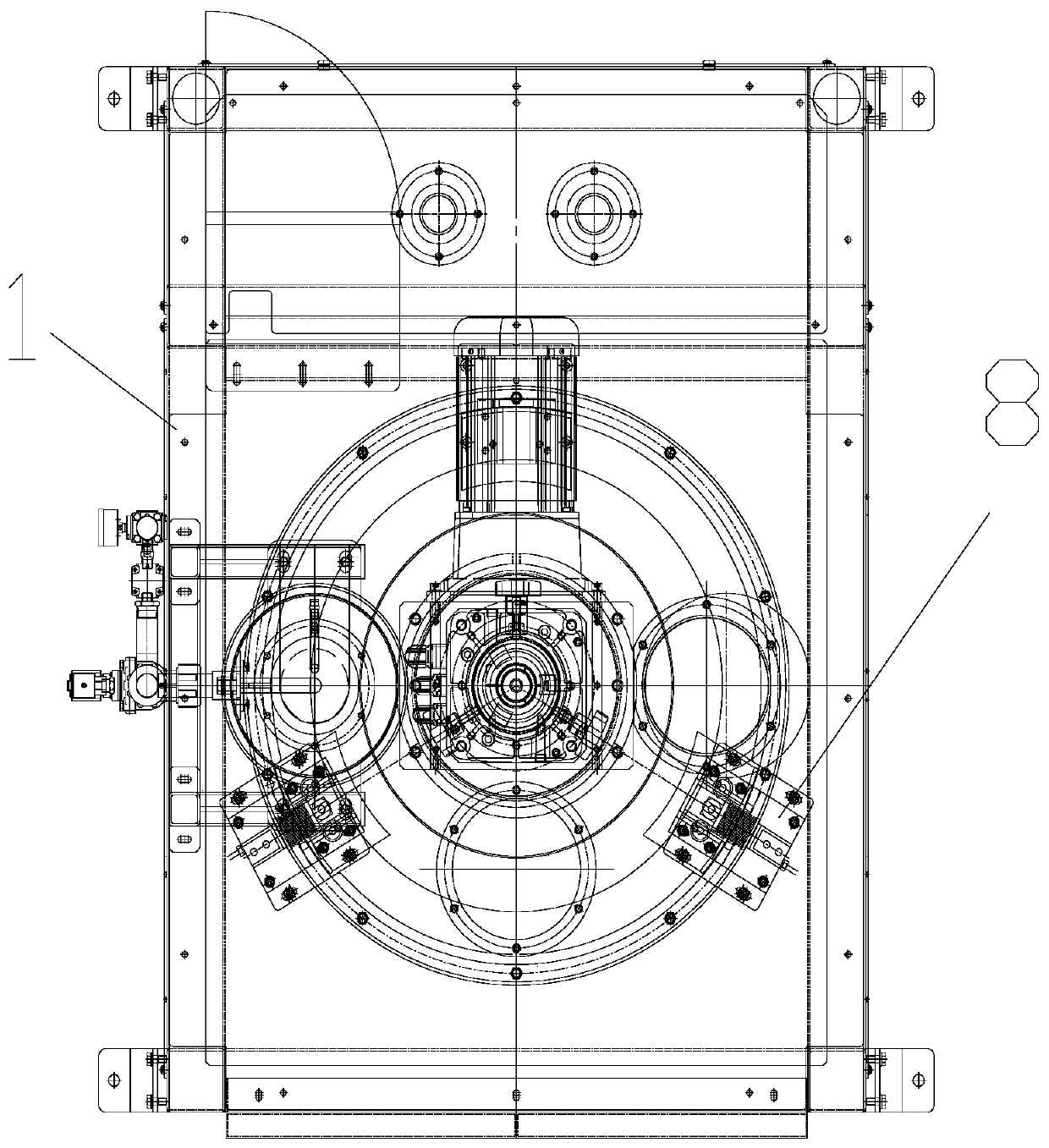

[0040] like Figure 8 , the feeding unit 4 includes a central screw feed assembly 41 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com