Construction steel structure carrying vehicle

A technology for a pallet truck and a steel structure, which is applied in the field of automatic loading trucks for building steel structures, can solve the problems of unsuitable steel structure transfer transportation or replacement of workshops, long conveying distance and high use cost, and achieves the range of power and transmission speed. The effect of large, low manufacturing cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means that the present invention realizes, creation feature, reach purpose and effect easy to understand, the present invention is further set forth below.

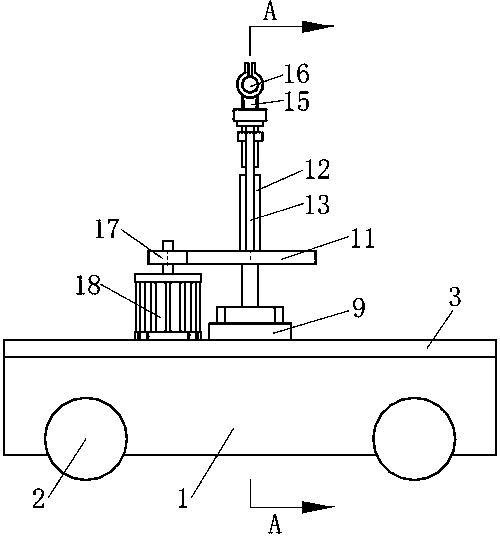

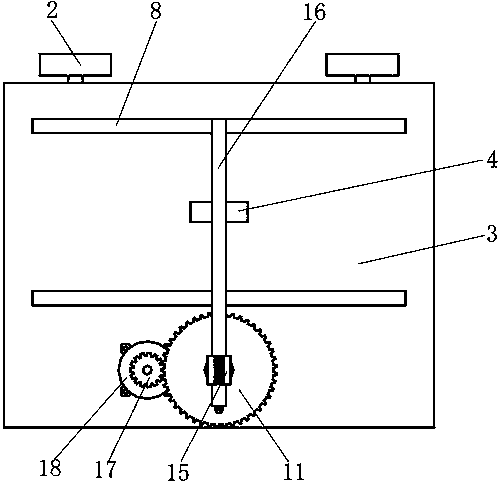

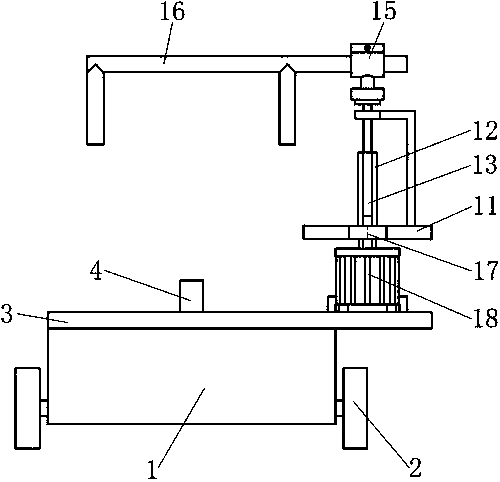

[0034] like Figure 1 to Figure 10 Shown, a kind of construction steel structure truck comprises vehicle body 1, and the both sides of described vehicle body 1 are equipped with traveling wheel 2, and the upper end of described vehicle body 1 is equipped with bearing plate 3, and the middle and lower part of described bearing plate 3 is installed with The lower compression clamping device, and the upper indexing clamping device is installed on the right side of the bearing plate 3 . When the middle part of the steel structure is placed sideways on the bearing plate 3 by driving, the lower compression clamping device will be driven to work, so as to limit the two sides of the lower part of the steel structure. After that, the upper indexing clamping device will start to work , when it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com