Solar-grade polycrystalline silicon product and production method thereof

A technology of polysilicon and polysilicon rods, which is applied in the field of solar-grade polysilicon products, can solve the unsatisfactory problems of product performance and energy saving and consumption reduction, and achieve the effect of increasing space utilization and efficient use of transportation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in detail through specific embodiments and drawings, but they are not intended to limit the present invention.

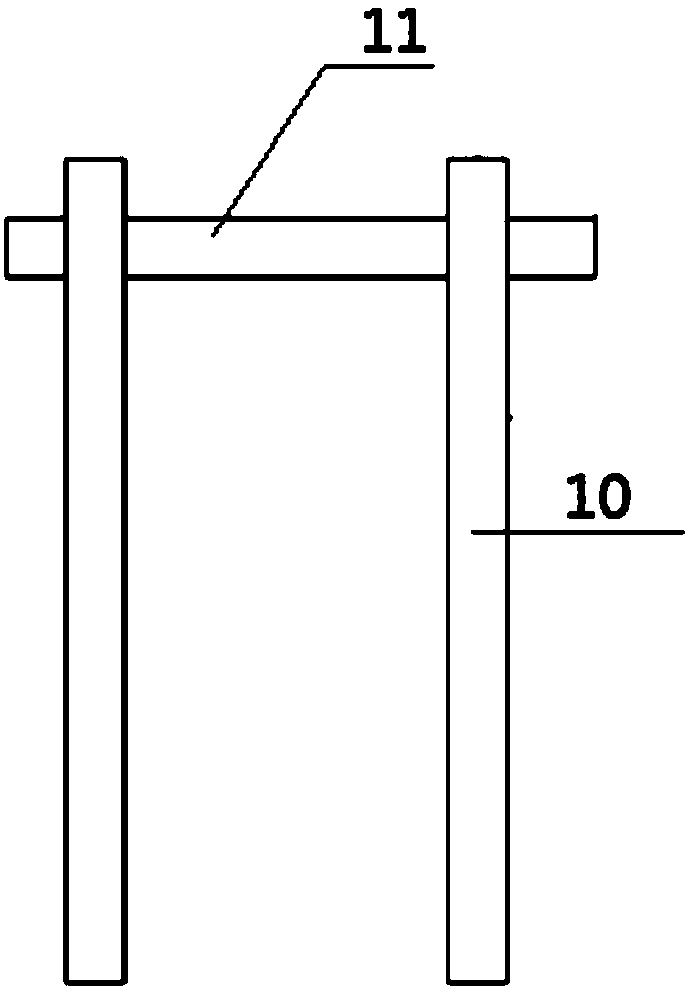

[0026] figure 1 The silicon core bridge structure of the present invention is shown, including silicon cores 10 and beams (bridges) 11 . During production, the silicon core 10 can be arranged in, for example, Figure 7 Shown on the bottom plate 1 of the reduction furnace.

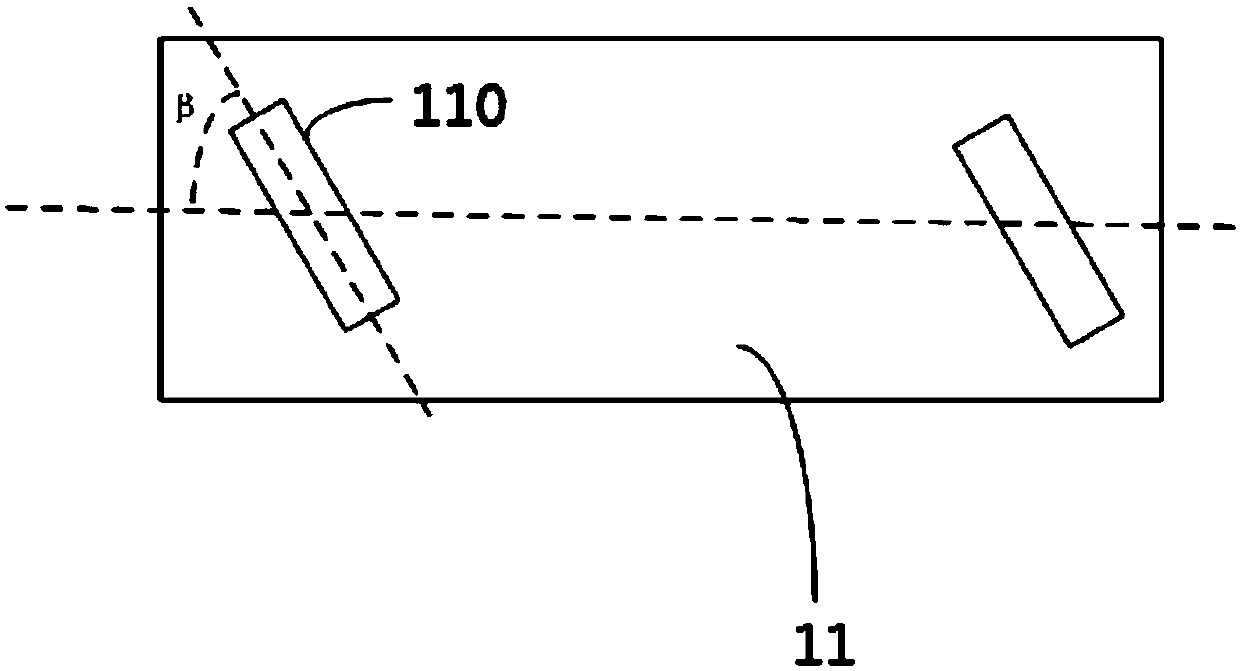

[0027] Such as Figure 5 As shown, the upper end of the silicon core 10 with a rectangular cross-section forms a tip 101 for easy insertion into the mounting holes 110 provided at both ends of the beam 11 which will be described in detail below.

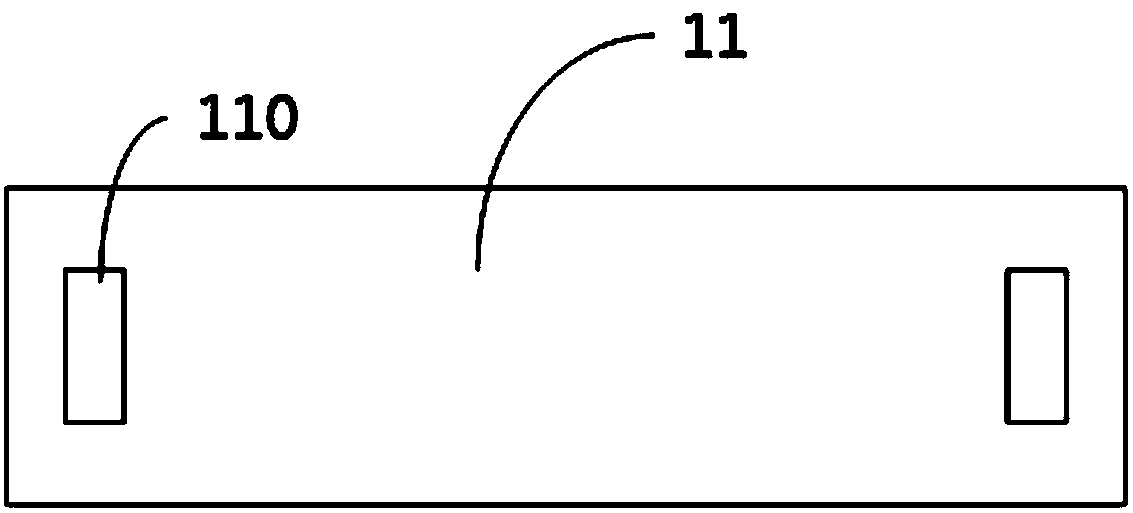

[0028] figure 2 One configuration of the beam 11 is shown. The beam 11 is a rectangular piece, which can be made of polycrystalline silicon, single crystal silicon or graphite, etc. by cutting, and a mounting hole 110 is opened at each end. The illustrated mounting hole 110 is also for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com