Quick-change oil and gas sealing system for high-speed wire rod mill

A high-speed wire and sealing system technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of aging and deformation of the sealing ring, entering the lubricating oil tank, and sealing effect failure, so as to improve the sealing effect and reduce the processing difficulty. , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

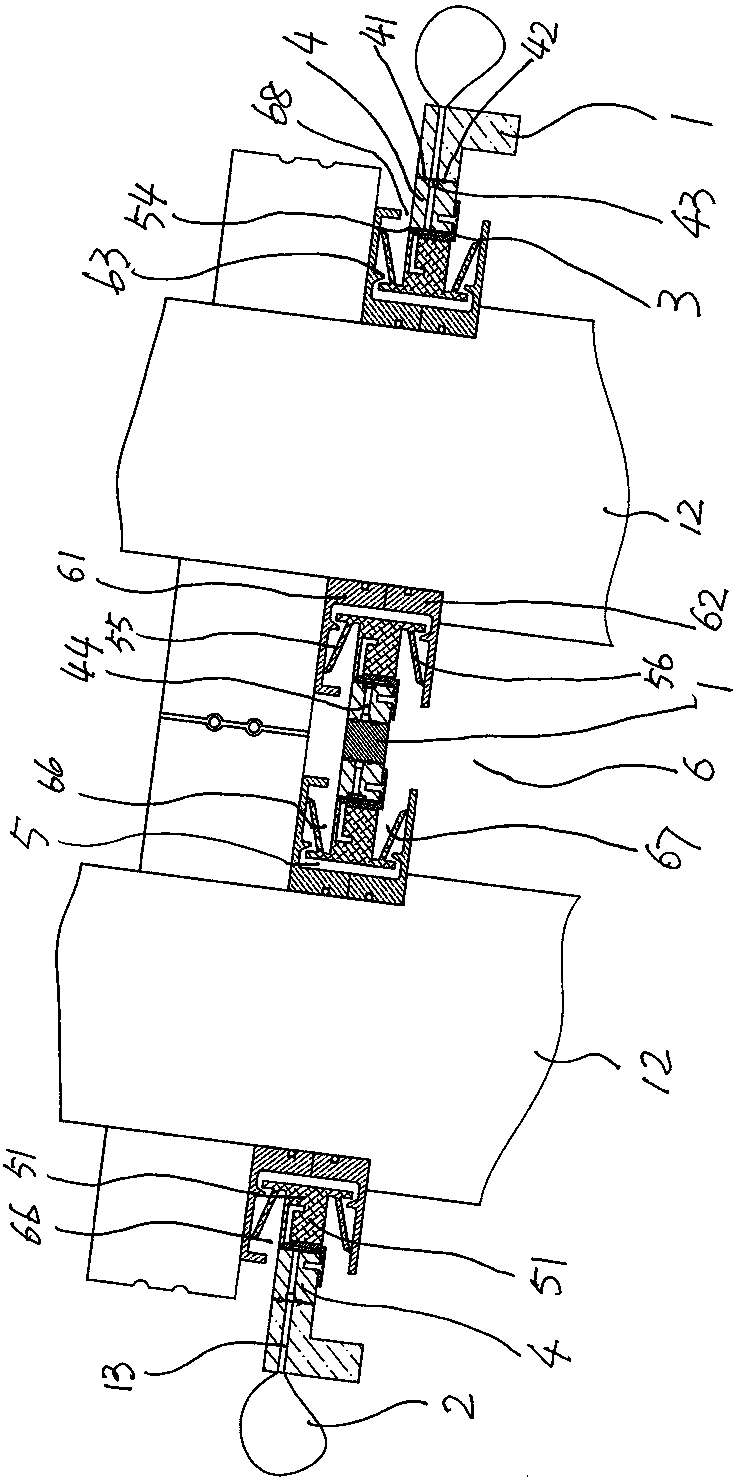

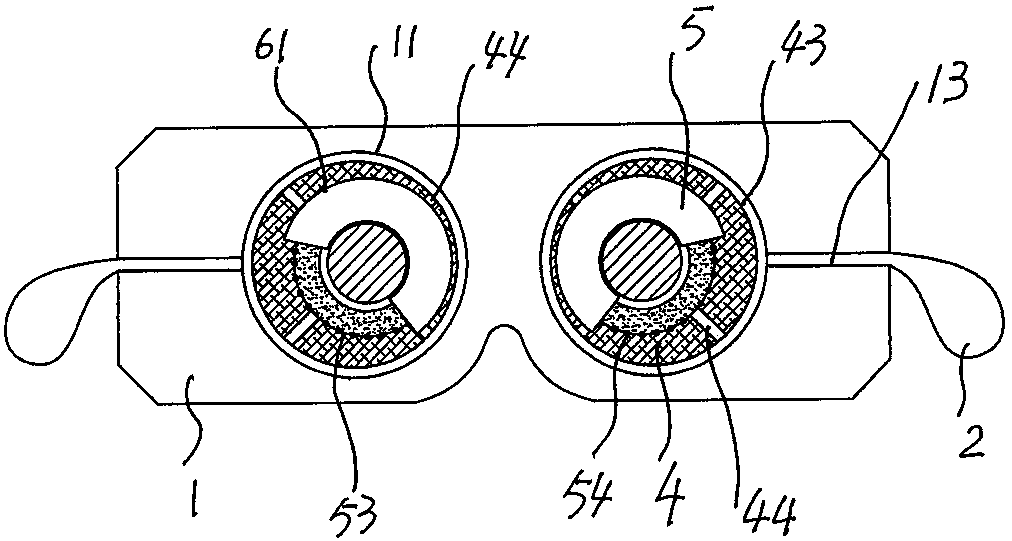

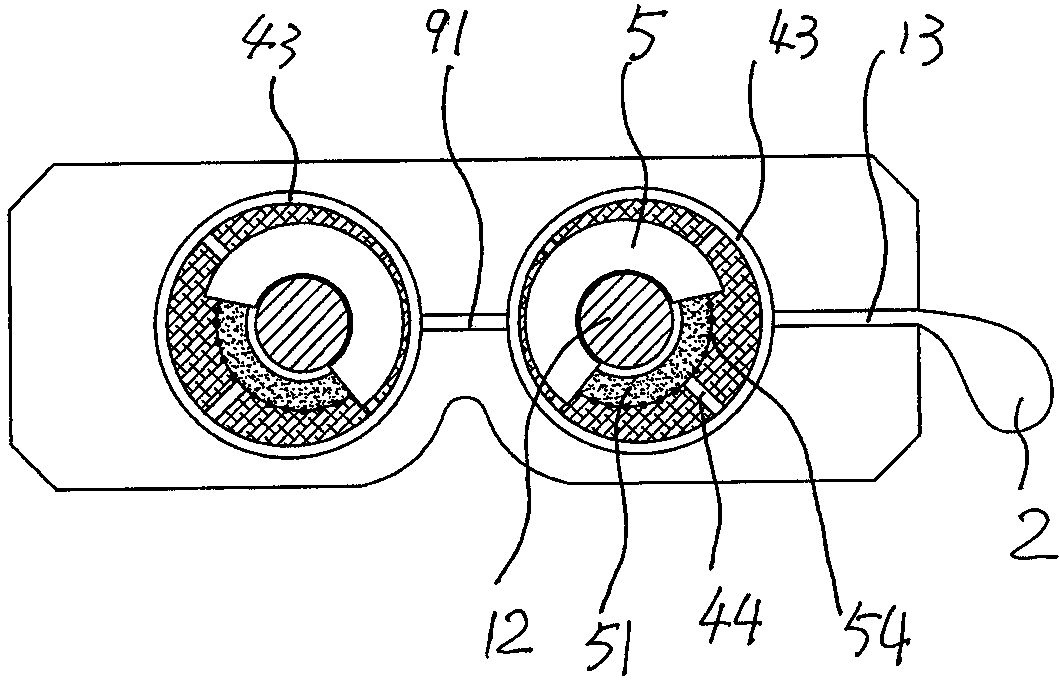

[0027] The structure and working principle of the quick-change oil-gas sealing system for a high-speed wire rolling mill provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] As shown in Figures 1, 2 and 3, it is a schematic structural diagram of the working principle of the quick-change oil-gas sealing system for a high-speed wire mill provided by the present invention. The structure constituting the quick-change oil-gas sealing system includes: two left and right "8"-shaped plates 1 for fixing the shaft holes 11 of the roll shaft are provided, and the two shaft holes are respectively provided with shafts for adjusting the left and right roll shafts. The eccentric disc 4 (also known as "quick-change oil-gas sealing plate") with a distance of 12 shafts is set on the sealing mechanism 5 in the eccentric disc; two seals are arranged on the outer circle of the above-mentioned eccentric disc, which can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com