A liquid level sensor device for a beer machine

A sensing device and liquid level sensor technology, which is applied in the direction of beer brewing, measuring device, engine lubrication, etc., can solve the problems of brewing coking, malt soaking enough, poor taste, etc., and achieve the effect of preventing coking and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

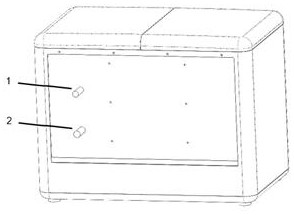

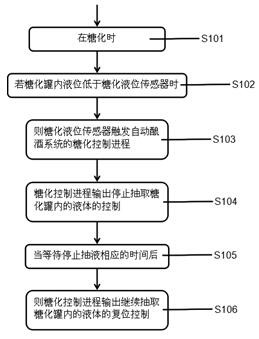

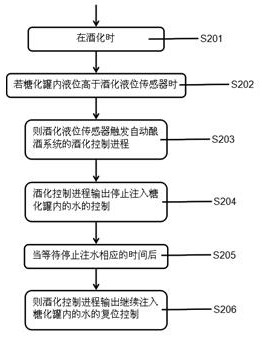

[0032] This embodiment: as figure 1 As shown, a liquid level sensor device for a beer machine, including a saccharification liquid level sensor 1 and a liquoration liquid level sensor 2 respectively arranged in the saccharification tank, the saccharification liquid level sensor 1 is used to automatically draw liquid at S101 during saccharification Processing, the alcoholization liquid level sensor 2 is used for S201 automatic water injection processing during alcoholization.

[0033] Since the saccharification liquid level sensor is used for automatic liquid extraction during saccharification, and the alcoholization liquid level sensor is used for automatic water injection during saccharification, since two liquid level sensors are installed behind the saccharification tank of the beer machine, The upper and lower ones do not interfere with each other. The "upper sensor limit" ensures that the malt is fully soaked during saccharification, and the "lower sensor limit" ensures t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com