Flat steel semi-finished product, method for producing a component, and use thereof

A technology of semi-finished products and flat steel, applied in chemical instruments and methods, layered products, aircraft parts, etc., can solve problems such as component failure, burden, and reduced deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

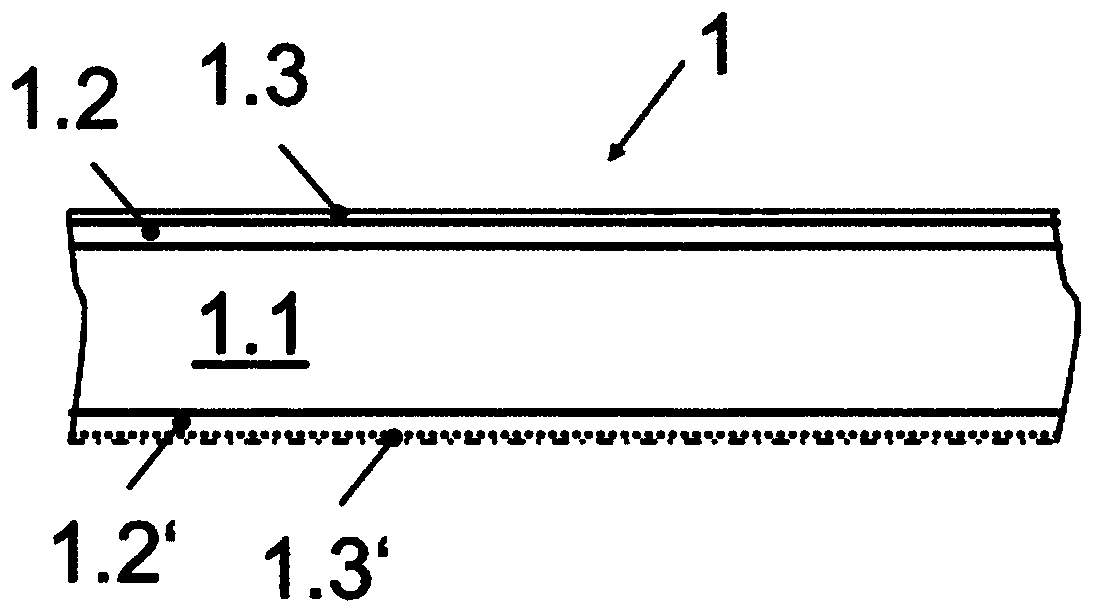

[0036] The single figure shows a schematic sectional view through a flat steel semi-finished product ( 1 ) according to the invention. The flat steel semi-finished product (1) according to the invention comprises a first layer (1.1) of a steel alloy (martensitic phase steel) with a martensitic structure, with a tensile strength > 1200 MPa and / or a hardness > 370 HV10, especially resistant to Tensile strength>1300MPa and / or hardness>400HV10, preferably tensile strength>1400MPa and / or hardness>435HV10, more preferably tensile strength>1500MPa and / or hardness>465HV10, especially preferred tensile strength>1600MPa and / or hardness> 490HV10, and two second layers (1.2, 1.2') consisting of mild steel alloys with a tensile strength < 600MPa, and / or a hardness < 190HV10, especially a tensile strength < 550MPa and / or a hardness < 175HV10, preferably resistant to With a tensile strength of <450 MPa and / or a hardness of <140 HV10, more preferably a tensile strength of <380 MPa and / or a ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com