Process method for achieving three surface finishing effects in one printing

A process method and technology of printing unit, applied in the post-processing of printing, printing, printing device, etc., can solve the problems of high cost and defect rate, inaccurate overprinting, low production efficiency, etc., to improve production efficiency and printing quality, The effect of improving position accuracy and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

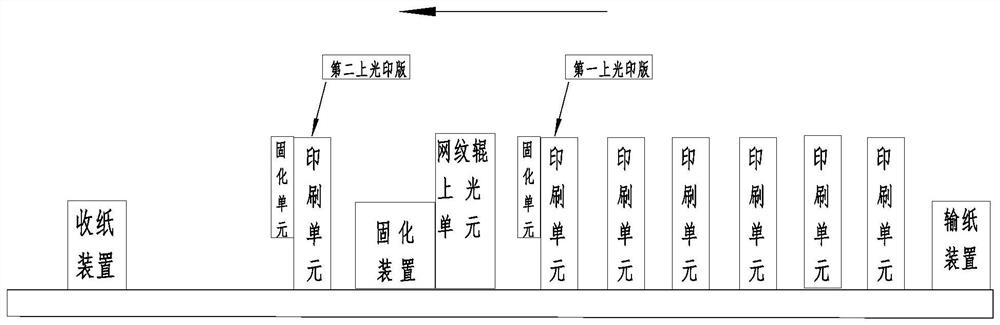

[0025] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. in figure 1 The right side is the "upstream" mentioned in this specification, and the left side is "downstream", figure 1 The plurality of printing units are respectively the first printing unit, the second printing unit, the third printing unit...the seventh printing unit from right to left.

[0026] See attached figure 1 The printing equipment shown is provided with a paper feeding device, 6 printing units, anilox roller glazing unit, curing device, 1 printing unit, and paper delivery device in sequence from upstream to downstream. The paper feeding device and paper delivery device form a basic Material delivery system for powering the substrate. The printing device also includes a first glazing printing plate having a first glazing area (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com