Automatic locking control system for container lifting appliance box landing and control method thereof

The technology of a container spreader and a control method is applied in the field of the control system for the automatic locking of the container spreader, which can solve the problems of shortening the service life of the handle and the hydraulic twist-lock cylinder, increasing the labor intensity of the driver, etc., so as to improve the reliability. and work efficiency, reduce labor intensity and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

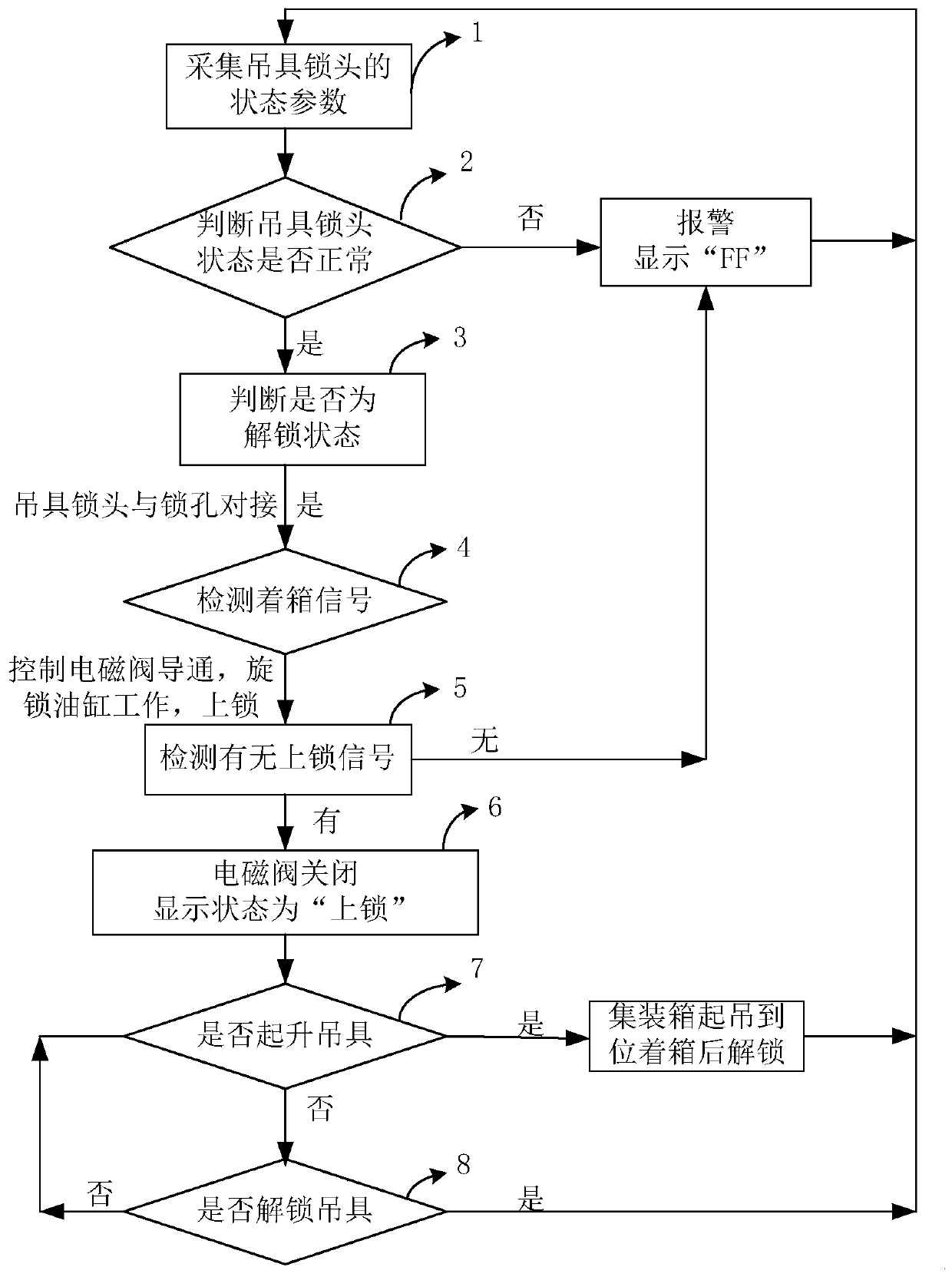

[0035] Such as image 3 As shown, a control method for automatic locking of a container spreader, comprising the following steps:

[0036] (1) Collect the signals detected by the loading sensor, unlocking sensor and locking sensor installed at the lock head of the spreader, and then judge the current state parameters of the lock head of the spreader according to the following table; among them, the loading sensor, unlocking sensor And the lock sensor is represented by "1" when the signal is detected, and "0" when the signal is not detected:

[0037] Check-in signal unlock signal lock signal Lock state of spreader 0 0 0 failure or power failure 0 0 1 Normal (locked) state 0 1 0 Normal (idle or unlocked) state 0 1 1 Fault 1 0 0 Malfunction or working during locking or unlocking 1 0 1 Normal (packed and locked) condition 1 1 0 Normal (boxed and unlocked) state 1 1 1 Fault

[0038] (2) According to...

Embodiment 2

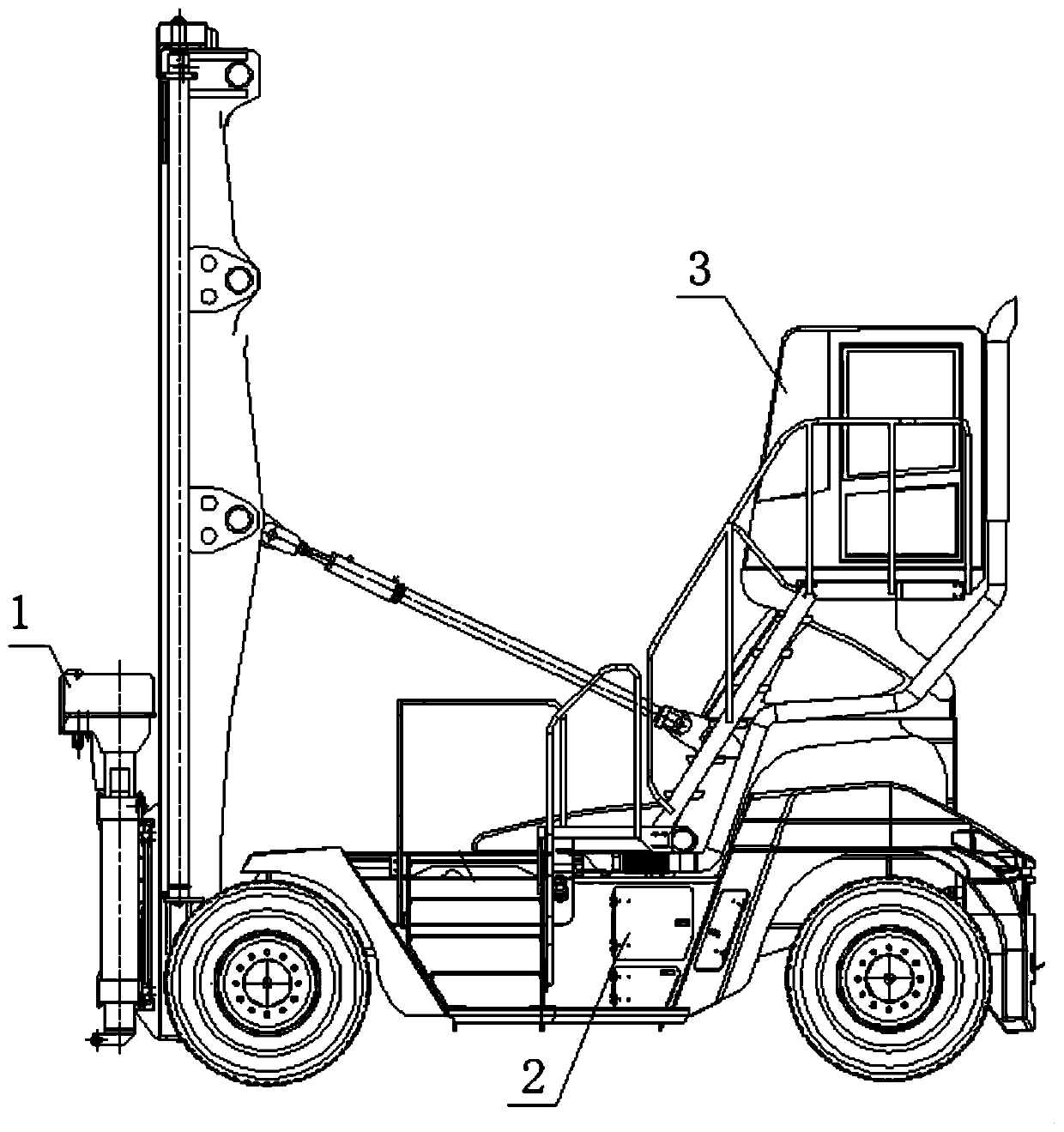

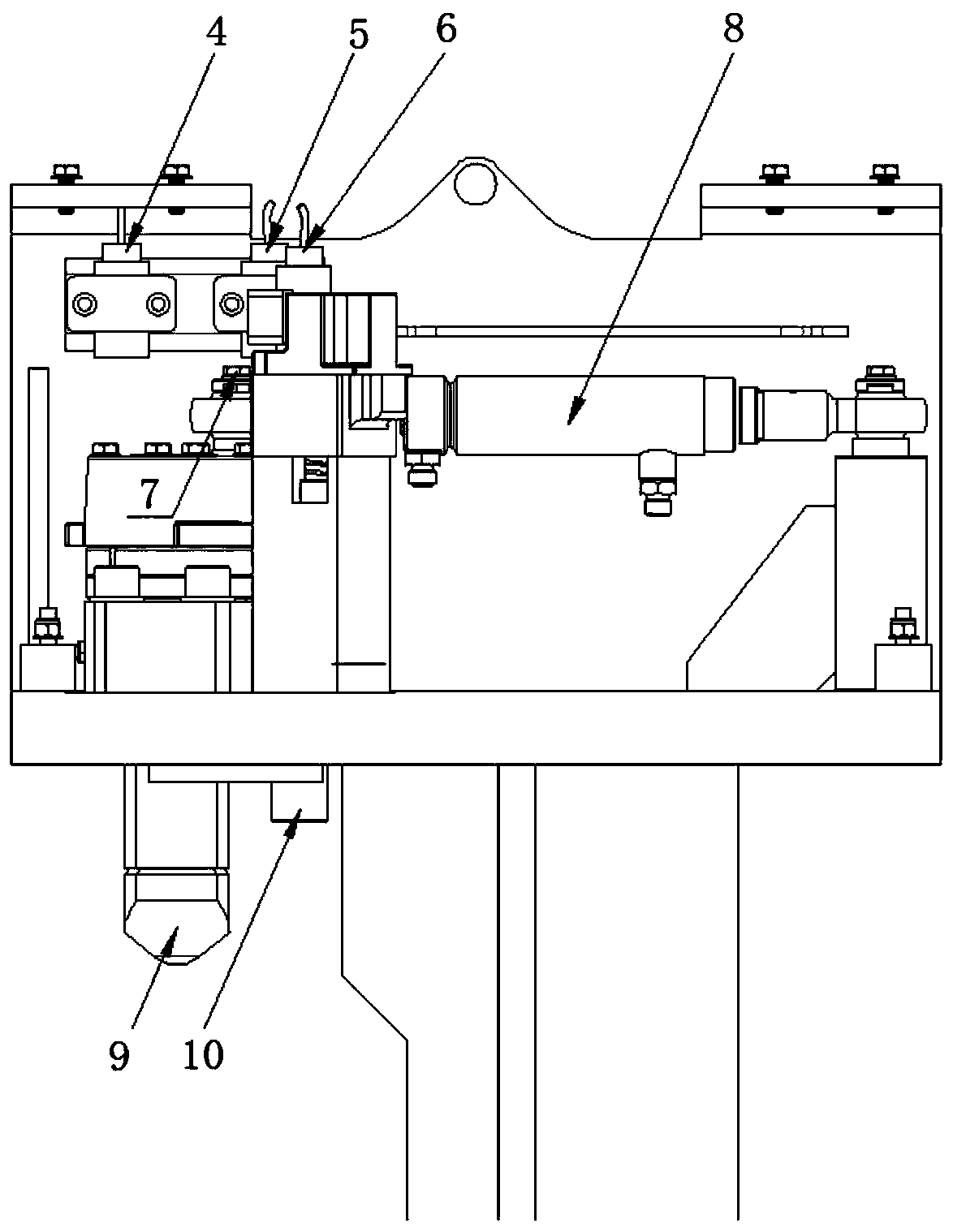

[0047] like Figure 1-3 As shown, a control system of a control method for automatic locking of a container spreader, including a vehicle controller 2, and a spreader lock head 9 and a twist lock cylinder 8 installed on a spreader 1, the spreader 1 The lock sensor 4, the unlock sensor 5 for detecting the lock head 9 of the spreader, and the box sensor 6 for detecting the contact between the spreader and the container are respectively installed on the top; the lock sensor 4, unlock sensor 5, box The signal output ends of the sensors 6 are all connected with the vehicle controller 2; the oil inlet end of the twist lock oil cylinder 8 is communicated with the output end of the hydraulic oil pump on the vehicle through a solenoid valve, and the output ends of the vehicle controller 2 are connected with the vehicle controller 2 respectively. The solenoid valve and the vehicle instrument 3 are electrically connected.

[0048] In a further scheme, the bottom end of the output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com