A low-cost black fdm printing wire prepared by recycling cigarette film masterbatch and its preparation method and application

A low-cost printing wire technology, applied in the field of materials, can solve the problems of expensive PLA-type 3D printing materials, increase the time and cost of production, and high printing costs, achieve good coloring effects, simplify production processes and processes, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the low-cost black FDM printing wire rod prepared by recycling cigarette film masterbatch according to the present invention comprises the following steps:

[0041] A. Dry the raw material recycled tobacco film masterbatch and polylactic acid (PLA) in a vacuum drying oven for 24 hours for later use;

[0042] B. Weigh the dried recycled cigarette film masterbatch and polylactic acid, compatibilizer, additives, and white oil according to the formula ratio, add them to the high-mixer and heat to 90~110°C, and stir at a speed of 4000~6000rpm for 30 ~50min to get material a;

[0043] C. Extrude material a through a twin-screw extruder, then cool to room temperature and send it to a pelletizer to cut to obtain material b;

[0044] D. Extrude material b through a die in a twin-screw extruder to obtain the target product.

[0045] The temperature of the twin-screw extruder described in step C is 150~210nb°C, and the rotation speed is 50~70rpm.

[00...

Embodiment 1

[0049] (1) The weight percentage formula is as follows:

[0050] Recycled tobacco film masterbatch 5

[0051] PLA 95

[0052] PE-g-MAH 2

[0053] DA-310ST 0.5

[0054] White oil 0.5

[0055] (2) Preparation method:

[0056] A. Place the reclaimed cigarette film masterbatch and PLA in a vacuum drying oven to dry;

[0057] B. According to the weight percentage formula, weigh the dried recycled cigarette film masterbatch, PLA, PE-g-MAH, P990, white oil;

[0058] C. Place the weighed components in a high-speed kneader, keep the speed at 2000 rpm, and stir at high speed for 20 minutes;

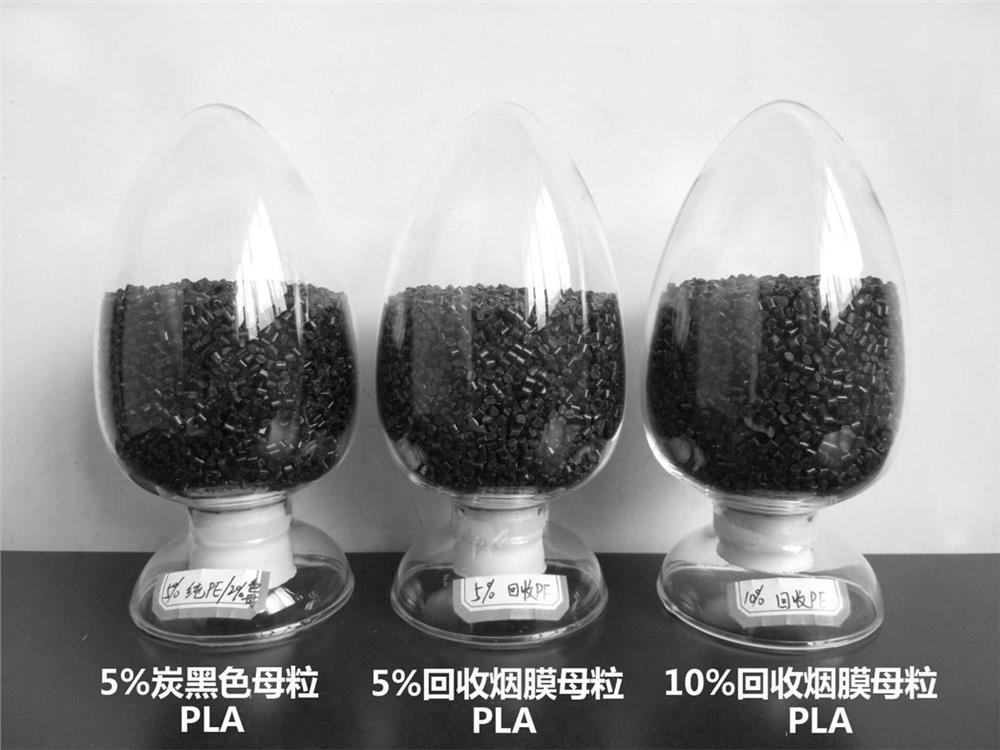

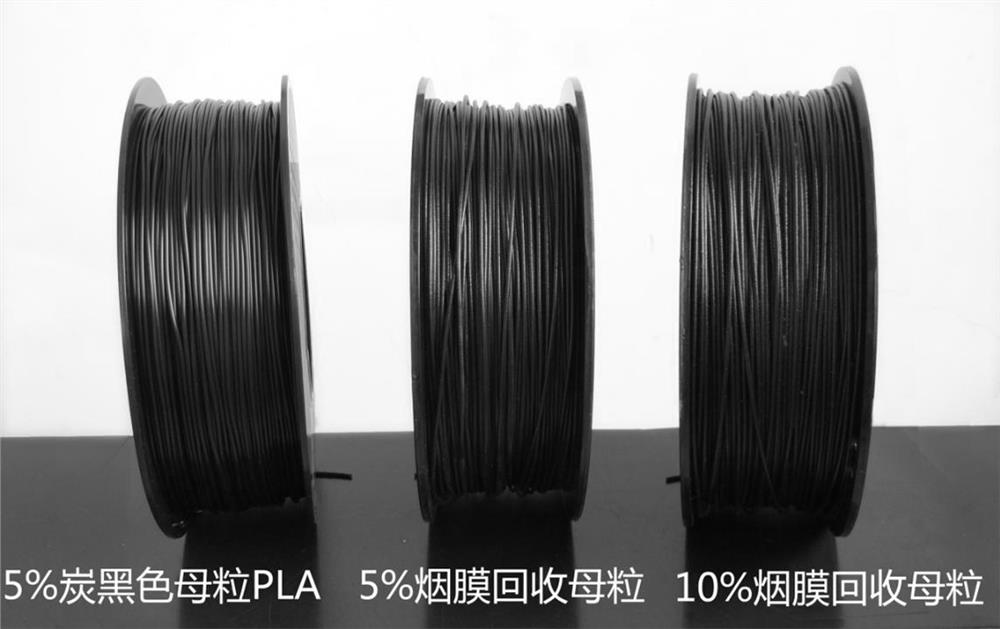

[0059] D. Add the uniformly mixed recycled cigarette film masterbatch, PLA, PE-g-MAH, P990, and white oil to the feeding port of the twin-screw extruder. The temperature of the twin-screw extruder is 150-210°C, and the rotation speed is 70rpm; The raw material extruded from the screw is sent to the pelletizer after being cooled and cut into pellets, such as figure 1 As shown, dry and set as...

Embodiment 2

[0064] (1) The weight percentage formula is as follows:

[0065] Recycled tobacco film masterbatch 10

[0066] PLA90

[0067] POE-g-GMA 5

[0068] DA-310ST 1

[0069] white oil 1

[0070] (2) Preparation method:

[0071] A. Place the reclaimed cigarette film masterbatch and PLA in a vacuum drying oven to dry;

[0072] B. According to the weight percentage formula, weigh the dried recycled cigarette film masterbatch, PLA, POE-g-GMA, DA-310ST, white oil;

[0073] C. Place the weighed components in a high-speed kneader, keep the speed at 1000-6000rpm, and stir at high speed for 5-30min;

[0074] D. Add the uniformly mixed recycled cigarette film masterbatch, PLA, POE-g-GMA, DA-310ST, and white oil to the feeding port of the twin-screw extruder. The temperature of the twin-screw extruder is 150-210°C, and the speed is 150rpm; the raw material extruded from the screw is cooled and sent to the pelletizer to be cut into pellets, such as figure 1 As shown, dry and set aside; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com