Cool circularly-knitted fabric

A fabric and cool feeling technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve the problems of resin easy to fall off, poor washing durability, etc., and achieve the effect of increasing the contact area, superior crispness, and reducing void ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

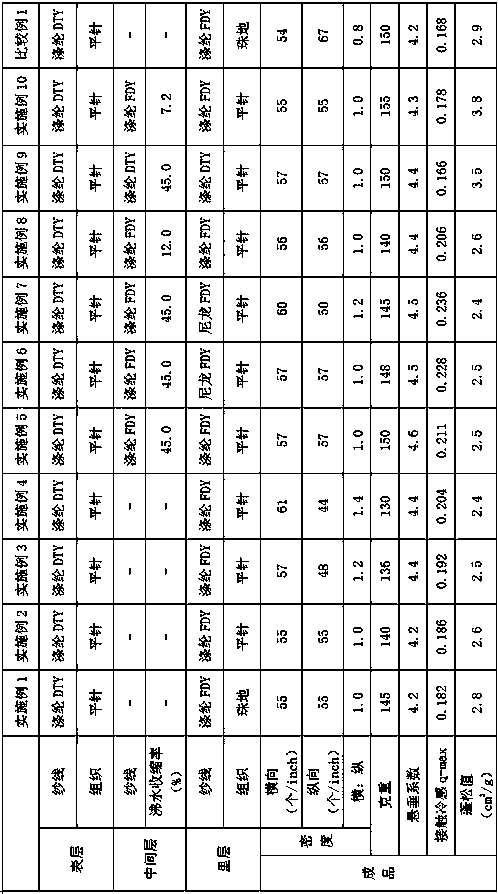

Embodiment 1

[0046] On the 28G double-sided circular knitting machine, the surface yarn uses 84dtex-72f-ordinary polyester DTY, the inner yarn uses 83dtex-36f-ordinary polyester FDY, and the weave adopts the double-sided weave of surface flat needle / inner piqué to obtain knitted gray fabric. After scouring and pre-shrinking under normal conditions (95°C×10 minutes), intermediate setting (temperature 180°C, longitudinal stretch rate 5%, transverse shrinkage rate 10%), dyeing and finishing processing (160°C×1 minute) After that, the ratio of transverse density to longitudinal density is 1.0, and the grammage is 145g / m 2 For fabrics, see Table 1 for specific parameters.

Embodiment 2

[0048] Weaving adopts the double-sided structure of surface flat stitch / back flat stitch, and all the other are the same as embodiment 1, and the ratio of obtaining horizontal density and vertical density is 1.0, and the gram weight is 140g / m 2 For fabrics, see Table 1 for specific parameters.

Embodiment 3

[0050]When setting in the middle, the longitudinal elongation rate is 15%, the transverse shrinkage rate is 15%, and all the other are the same as in Example 2, and the ratio of obtaining the transverse density and the longitudinal density is 1.2, and the grammage is 136g / m 2 For fabrics, see Table 1 for specific parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| drape coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com