Logistics control system and method with artificial intelligence

A technology of artificial intelligence and control method, applied in the field of intelligent logistics, can solve problems such as insufficient utilization of resources, and achieve the effect of reducing space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

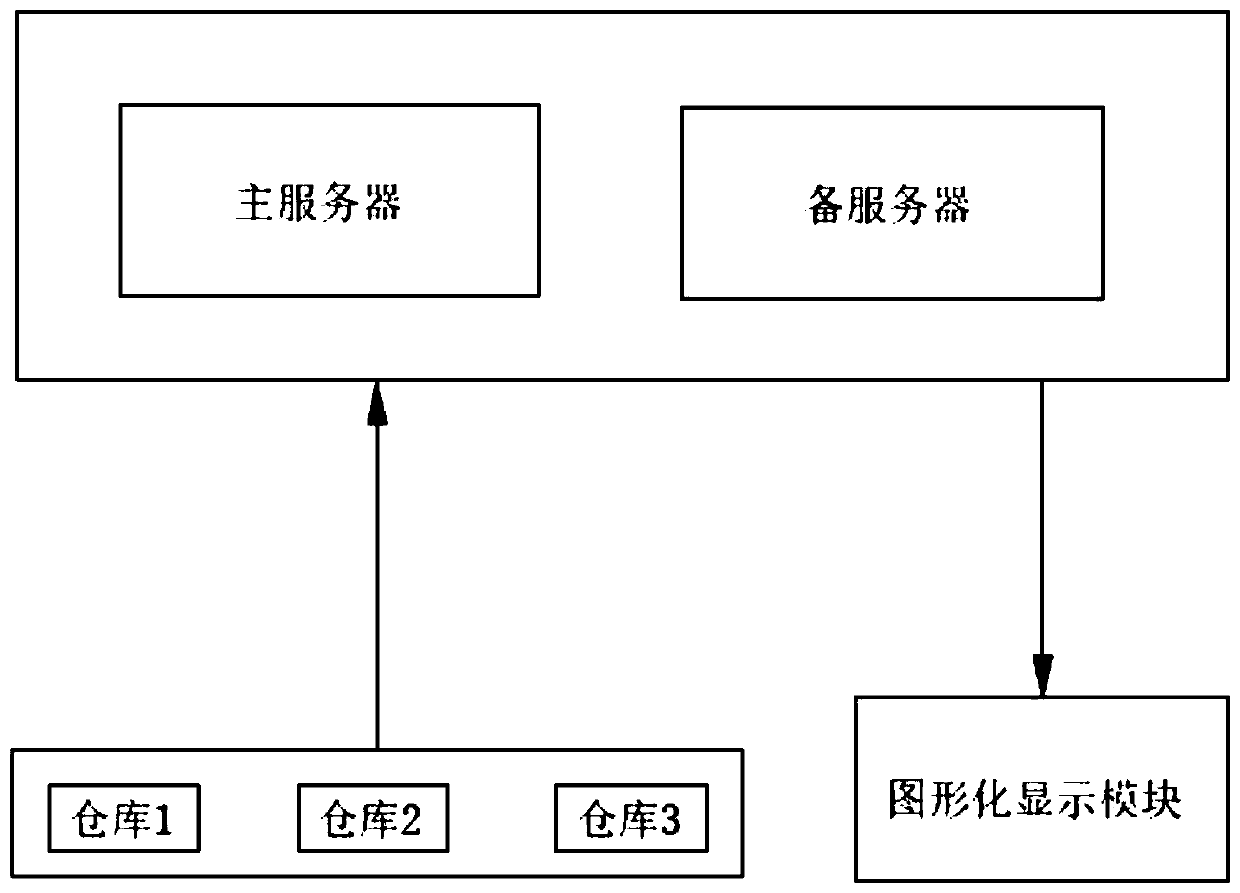

[0023] A logistics control system equipped with artificial intelligence, including a cloud system module, a data acquisition module, and a graphical display module, wherein the cloud system module includes a master server and a backup server, and the master server and the backup server include A data collection unit, a data calculation unit and a data analysis unit.

[0024] Furthermore, the region and the products ordered by customers in each region are uploaded to the main server as features, and the main server builds a prediction model with the collected information, and the staff promptly configures the goods in the corresponding region’s warehouse with the same goods as the model’s prediction results. There is only one working between the server and the standby server at the same time and the data is synchronized in real time. When the failure of the primary server is detected, the standby server becomes the primary server.

[0025] Through the above technical solution, ...

Embodiment 2

[0033] A logistics control system equipped with artificial intelligence, more specifically, clothing including shirts for men, dresses for girls and sneakers for children. Warehouses include Shanghai Warehouse, Beijing Warehouse, and Chengdu Warehouse. The warehouse and the corresponding clothing sales volume are put into the supervised learning algorithm as the training data set, and the weight is calculated to obtain the model. It is predicted that the Shanghai Warehouse should store 100 pieces of men’s shirts, 120 sets of girls' dresses, 140 pairs of children's sports shoes, Beijing warehouse should store 200 pieces of men's shirts, 220 sets of girls' dresses, 240 pairs of children's sports shoes, Chengdu warehouse should store 300 pieces of men's shirts, 320 sets of girls' dresses, and 340 pairs of children's sports shoes . If you find that there are only 10 men’s shirts in the Shanghai warehouse, you should pre-order enough shirts in advance. If you find that there are 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com