Color protecting technology for processing and producing convenient hotpot vegetable bag from high-salt salty raw materials

A technology for convenient hot pot and vegetable bag, which is applied in food science and other directions to achieve the effect of solving the problem of perennial supply, wide application and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

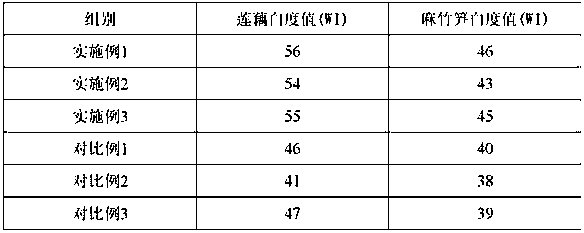

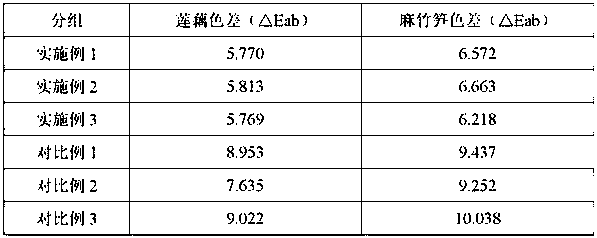

Examples

Embodiment 1

[0031] A color protection process for processing high-salt salted raw materials to produce instant hot pot vegetable buns

[0032] (1) Selection and removal of impurities: manual selection of high-salt salted lotus root and high-salt salted bamboo shoots (concentration: 13%) that do not meet the specifications and have abnormal color;

[0033] (2) Prepare desalinated water: completely dissolve 0.1% sodium erythorbate, 0.02% EDTA, 0.04% sodium metabisulfite and 0.06% citric acid in sterile drinking water, adjust the pH value to 4.7, and obtain desalinated water for later use;

[0034] (3) One-time desalination: Put high-salt salted lotus root and high-salt salted bamboo shoots into desalted water of equal quality, turn on the aeration device (the purpose of aeration is to fully mix the material and desalinated water), aerate and desalinate for 20 minutes, Then static desalination for 24 hours, the desalted water should completely submerge the materials, and the first desalted l...

Embodiment 2

[0043] A color protection process for processing high-salt salted raw materials to produce instant hot pot vegetable buns

[0044] (1) Selection and removal of impurities: manual selection of high-salt salted lotus root and high-salt salted bamboo shoots (concentration: 10%) that do not meet the specifications and have abnormal color;

[0045] (2) Prepare desalinated water: completely dissolve 0.1% sodium erythorbate, 0.02% EDTA, 0.04% sodium metabisulfite and 0.06% citric acid in sterile drinking water, adjust the pH value to 4.6, and obtain desalinated water for later use;

[0046] (3) One-time desalination: Put high-salt salted lotus root and high-salt salted bamboo shoots into desalted water of equal quality, turn on the aeration device (the purpose of aeration is to fully mix the material and desalinated water), aerate and desalinate for 20 minutes, Then static desalination for 24 hours, the desalted water should completely submerge the materials, and the first desalted l...

Embodiment 3

[0055] A color protection process for processing high-salt salted raw materials to produce instant hot pot vegetable buns

[0056] (1) Selection and removal of impurities: manual selection of high-salt salted lotus root and high-salt salted bamboo shoots (concentration: 17%) that do not meet the specifications and have abnormal color;

[0057] (2) Prepare desalinated water: completely dissolve 0.1% sodium erythorbate, 0.02% EDTA, 0.04% sodium metabisulfite and 0.06% citric acid in sterile drinking water, adjust the pH value to 4.9, and obtain desalinated water for later use;

[0058] (3) One-time desalination: Put high-salt salted lotus root and high-salt salted bamboo shoots into desalted water of equal quality, turn on the aeration device (the purpose of aeration is to fully mix the material and desalinated water), aerate and desalinate for 20 minutes, Then static desalination for 24 hours, the desalted water should completely submerge the materials, and the first desalted l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com