Composite type waste gas treatment device

A kind of waste gas treatment equipment and composite technology, which can be used in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to remove particulate matter and dust, and achieve good purification effect, speed up flow rate, and improve the effect of filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

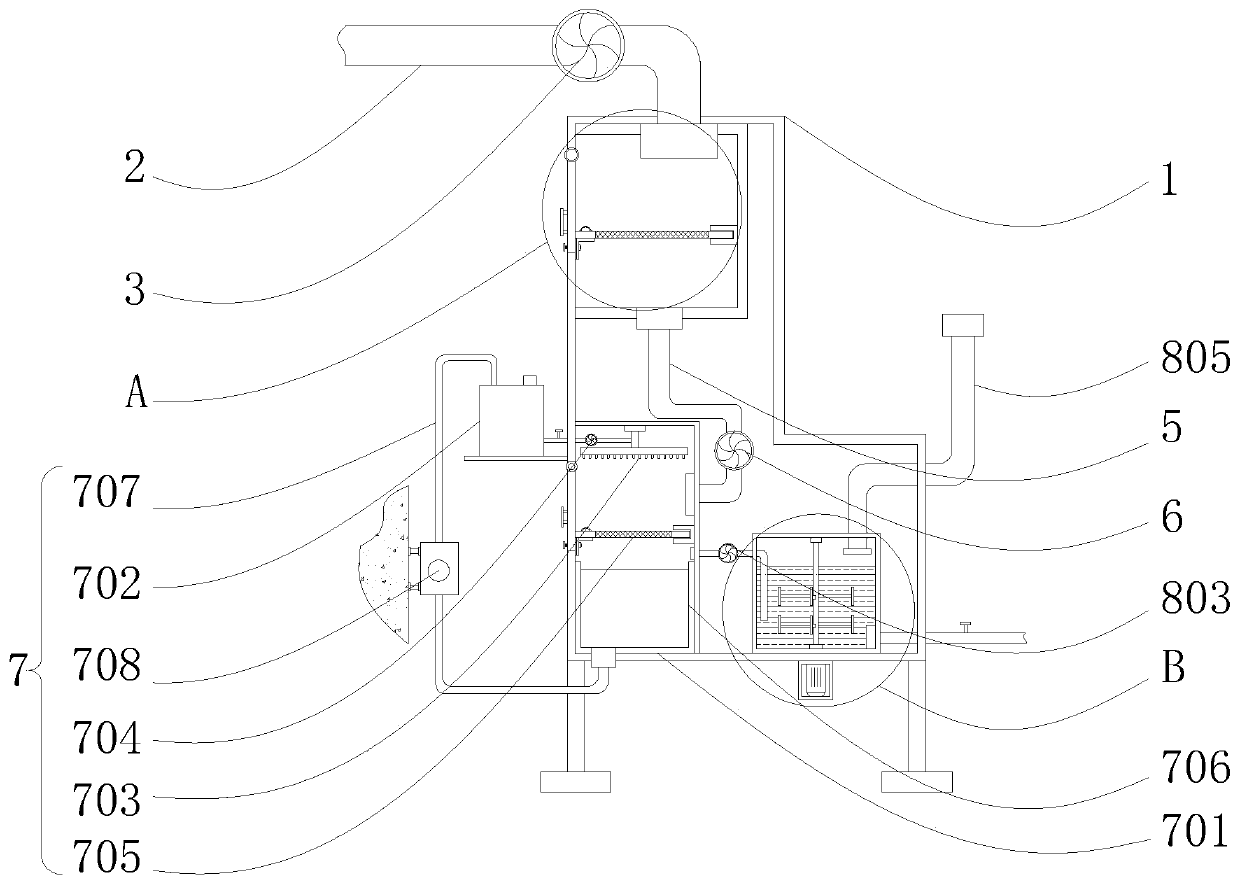

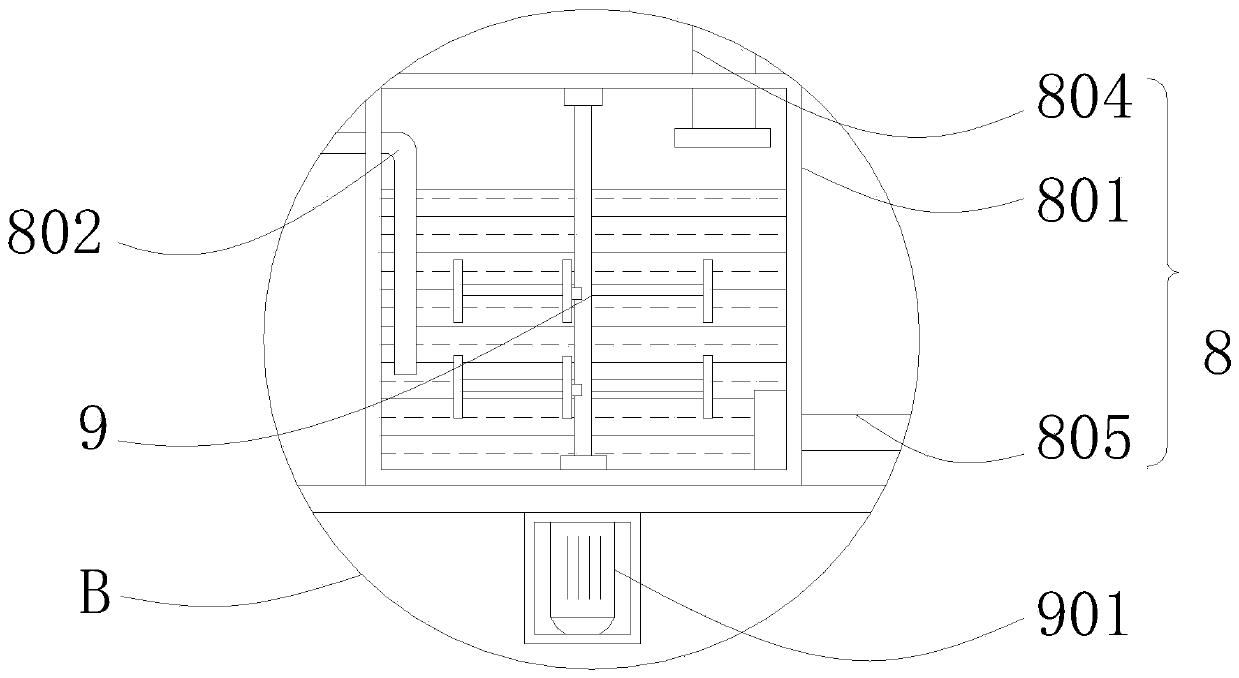

[0028] see Figure 1-4 , the present invention provides the following technical solutions: a compound exhaust gas treatment equipment, including a casing 1, a smoke pipe 2, a first air pump 3, a filter device 4, a gas delivery pipe 5, a second air pump 6, a settling device 7, and a purification device 8 and the stirring device 9, the smoke pipe 2 is connected to the upper end of the casing 1, the first air pump 3 is fixedly connected between the smoke pipes 2, the filter device 4 is connected to the lower end of the smoke pipe 2, and the air pipe 5 is connected to the lower end of the filter device 4 , the second air pump 6 is fixedly connected between the gas delivery pipes 5, the settling device 7 is connected to the lower end of the gas delivery pipe 5, the purification device 8 is connected to one side of the settling device 7, and the stirring device 9 is rotatably connected to the inside of the purification device 8.

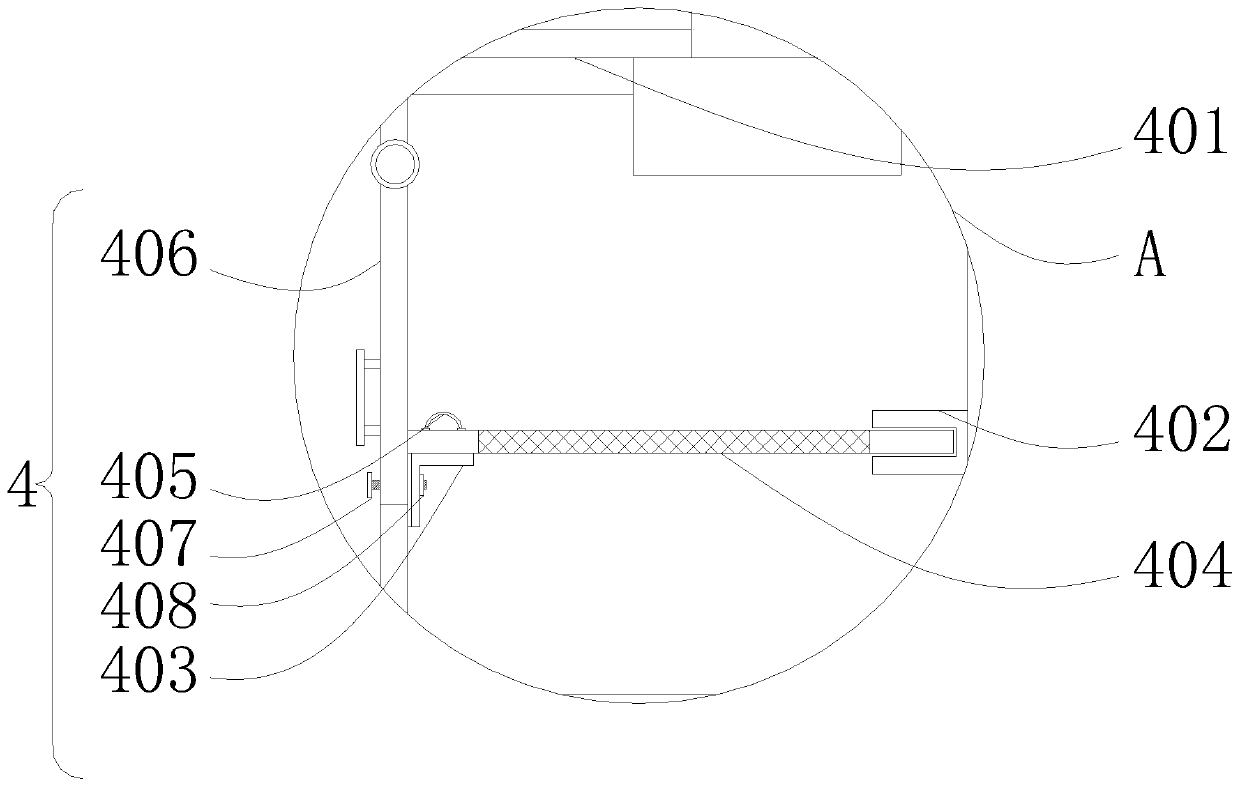

[0029] The filter device 4 includes a filter box 401...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com