Underground engineering radon gas adsorption treatment apparatus

A technology of adsorption treatment and underground engineering, applied in gas treatment, nuclear engineering, membrane technology, etc., can solve the problems of secondary pollution, easy desorption, easy saturation, etc., to reduce the amount of use, reduce the resistance of activated carbon, and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

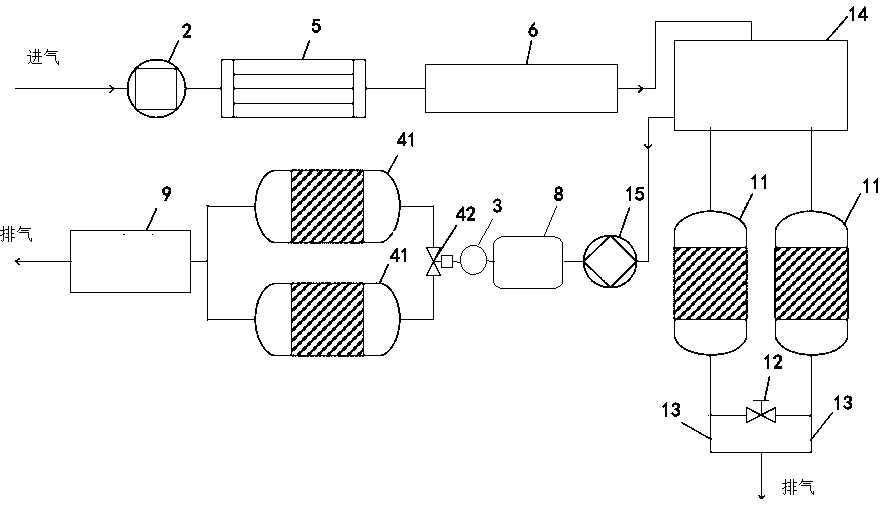

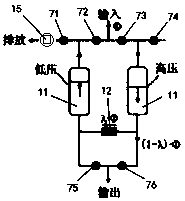

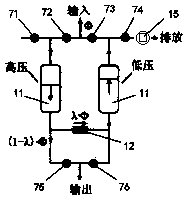

[0026] like figure 1 The shown underground engineering radon adsorption treatment device includes a plurality of activated carbon beds 11 for adsorbing radon or desorbing radon, air compressor 2 that will contain radon air from the source into the activated carbon bed, and the activated carbon bed 11 is at least two A throttling valve 12 is installed between adjacent activated carbon beds, so that the air flow circulates between adjacent activated carbon beds; an exhaust pipe 13 is connected to the connecting pipe between each end of the throttle valve 12 and the activated carbon bed 11, including After the radon air is compressed by the air compressor 2, it is sent into one or more activated carbon beds 11 through the electromagnetic valve 14 for radon adsorption. After that, part of the air coming out of the activated carbon beds 11 for radon adsorption is discharged through the exhaust pipe 13. (The air adsorbed by the activated carbon bed is clean air), the other part ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com