Upper part C-ring cutting device of canned-motor pump

A technology of cutting device and bottom support, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine tool parts, etc., can solve the problems such as complex structure of cutting device, achieve positioning and stable operation in the circumferential direction, The effect of avoiding pollution and ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0034] After removing the main bolts of the shielded main pump and leaving four symmetrical bolts, the upper C-ring of the shielded main pump is cut by an upper C-ring cutting device of the present invention.

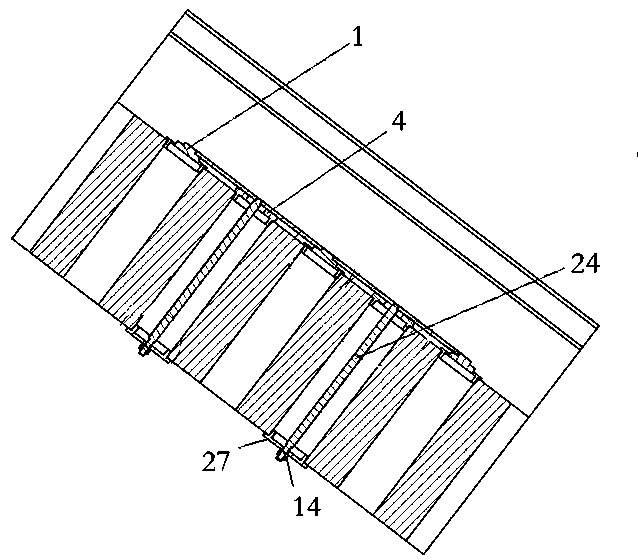

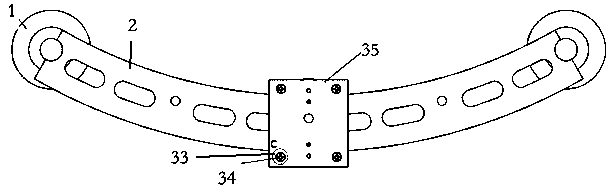

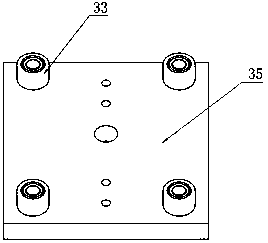

[0035] Such as figure 1 , A C-ring cutting device for shielding the upper part of the main pump of the present invention includes a circumferential guide rail 2 , a circumferential slider 6 , a radial guide rail 7 , a radial slider 8 , and an angle grinder 10 . The circumferential guide rail 2 is installed on the main pump flange 13 through the circumferential support body assembly, so that there is a gap between the circumferential guide rail 2 and the main pump flange 13, that is, the circumferential guide rail is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com