Swing feeding mechanism for carrying out precision extrusion forming of parts with internal and external teeth based on generating method

A technology of extrusion forming and feeding mechanism, applied in the field of swing feeding mechanism, can solve the problems of complex structure, high economic cost and large space occupation, and achieve the effects of low economic cost, high feeding accuracy and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

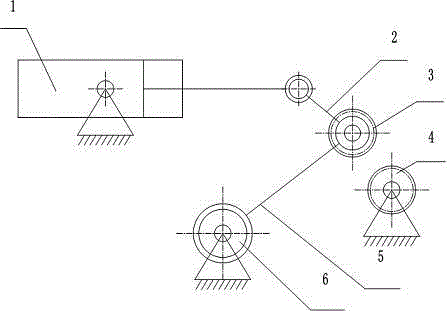

[0011] As an embodiment of the present invention, such as figure 1 As shown, an oscillating feed mechanism for precision extrusion molding parts with internal and external teeth based on the generation method, including a main shaft mold 4 and a pressing wheel mold 3, the main shaft mold 4 is installed on the main shaft, and the pressing wheel mold 3 is installed on the pressing wheel. On the wheel shaft, the pressure roller shaft is installed on the pressure roller shaft seat 2, and the pressure wheel shaft seat 2 is connected with the piston rod of the servo cylinder 1 through a pin shaft, and also includes a swing arm 5, one end of the swing arm 5 is connected with the pressure wheel shaft, and the other end is hinged on the On the swing hinge support 6. The linear motion of the driven servo cylinder 1 is transformed into the circumferential swing of the swing arm 5 , thereby realizing the radial feed between the pinch roller mold 3 and the spindle mold 4 . As a preference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com