Polystyrene light guide plate

A polystyrene and light guide plate technology, applied in the field of light guide plates, can solve problems such as light guide plate fixation, light guide plate thickness, light guide plate cutting size deviation, etc., to achieve a clean working environment, better light guide effect, and cutting smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

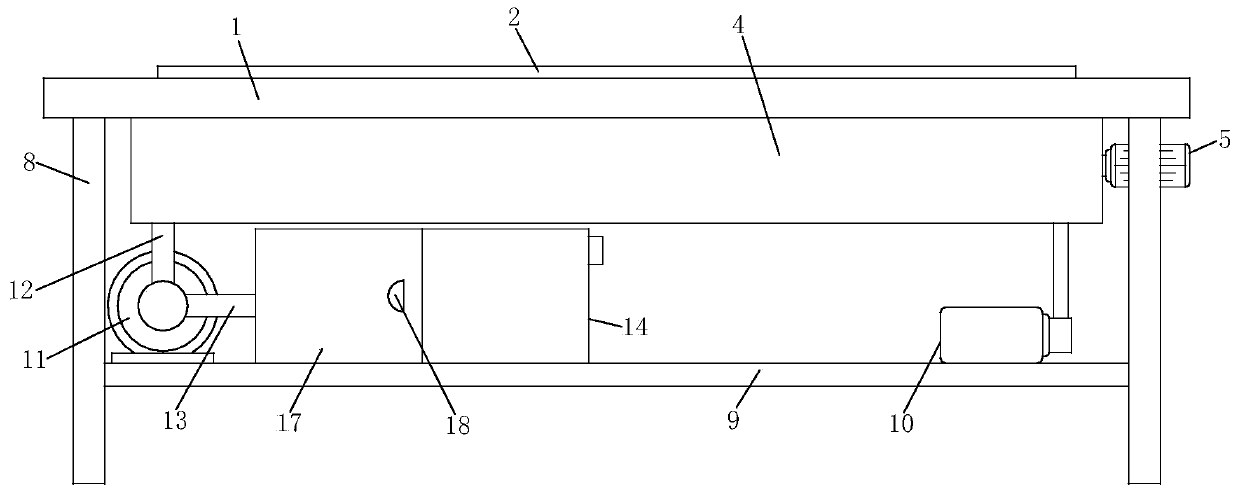

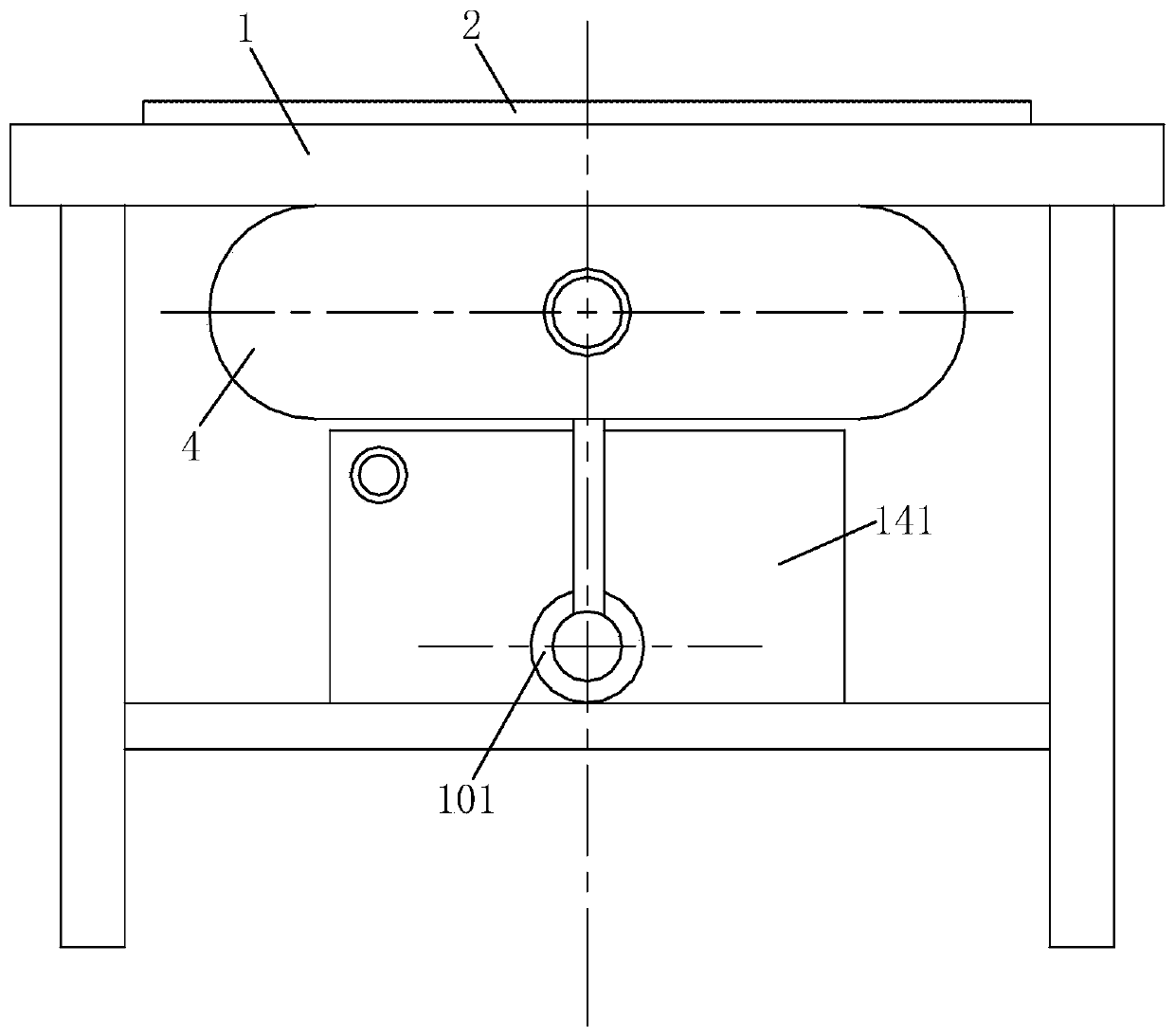

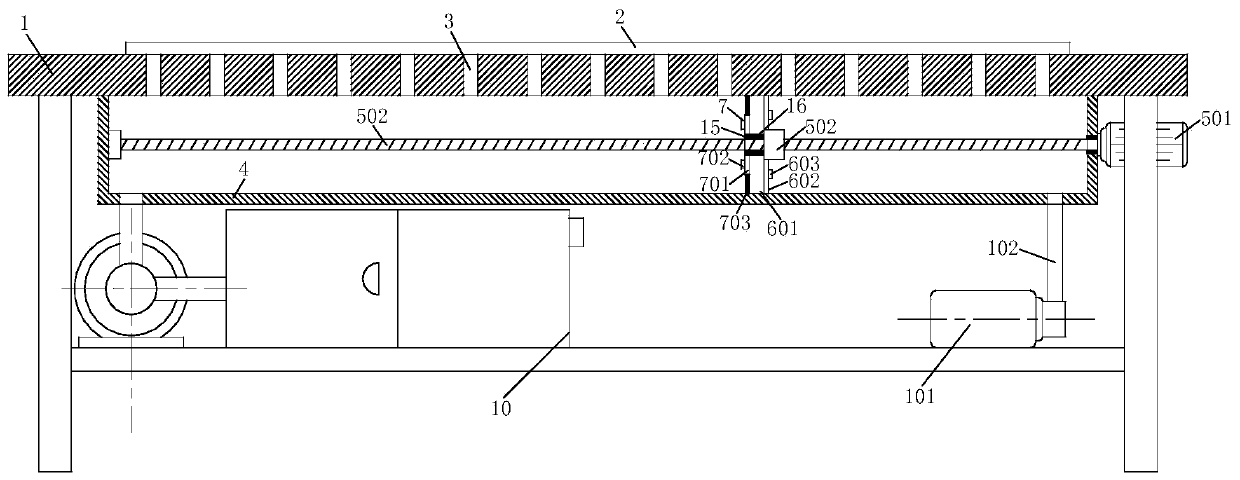

[0026] Such as Figure 1-Figure 6 As shown, a polystyrene light guide plate according to the present invention includes a cutting table 1, a light guide plate body 2 is placed on the upper surface of the cutting table 1, and through holes are evenly opened on the cutting table 1. 3, and the through hole 3 is evenly opened in a rectangular shape and the cutting table 1 is close to the middle position, the lower surface of the cutting table 1 is fixedly installed with the box body 4 corresponding to the through hole 3, and the upper surface of the box body 4 is Opening structure, the transmission mechanism 5 is fixedly installed in the box body 4, and the sealing mechanism 6 for sealing the inner wall of the box body 4 is fixedly installed on the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com