Assembling clamp for scissors legs

A technology for assembling fixtures and scissor feet, which is applied in the field of assembling fixtures for scissor feet, and can solve problems such as increased labor costs, personnel noise and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] This embodiment provides an assembly fixture for scissor feet.

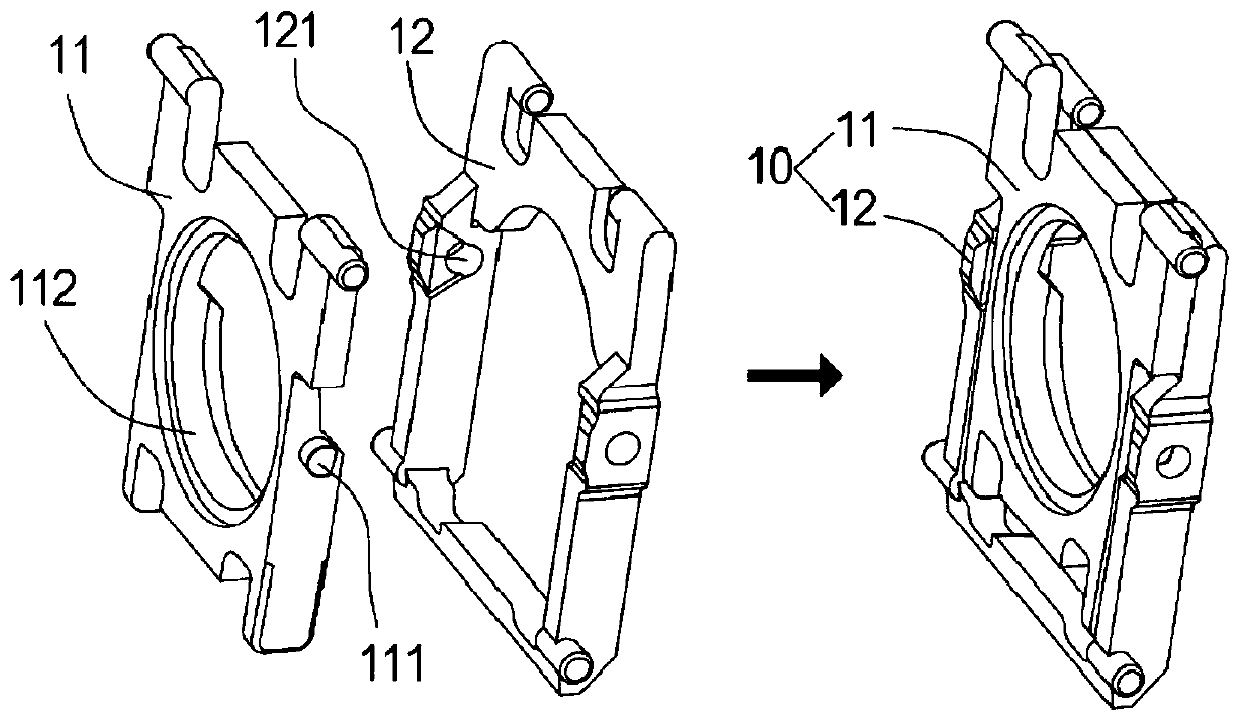

[0040] Such as figure 1 As shown in , the scissor foot 10 includes the scissor foot inner part 11 and the scissor foot outer frame 12. In this embodiment, the process of installing the scissor foot inner part to the scissor foot outer frame to form the scissor foot is called assembly, and the assembly is The two shafts 111 on the scissors inner part are pressed into the two shaft holes 121 of the scissors outer frame, and the assembled scissors inner part and the scissors outer frame can be relatively movable.

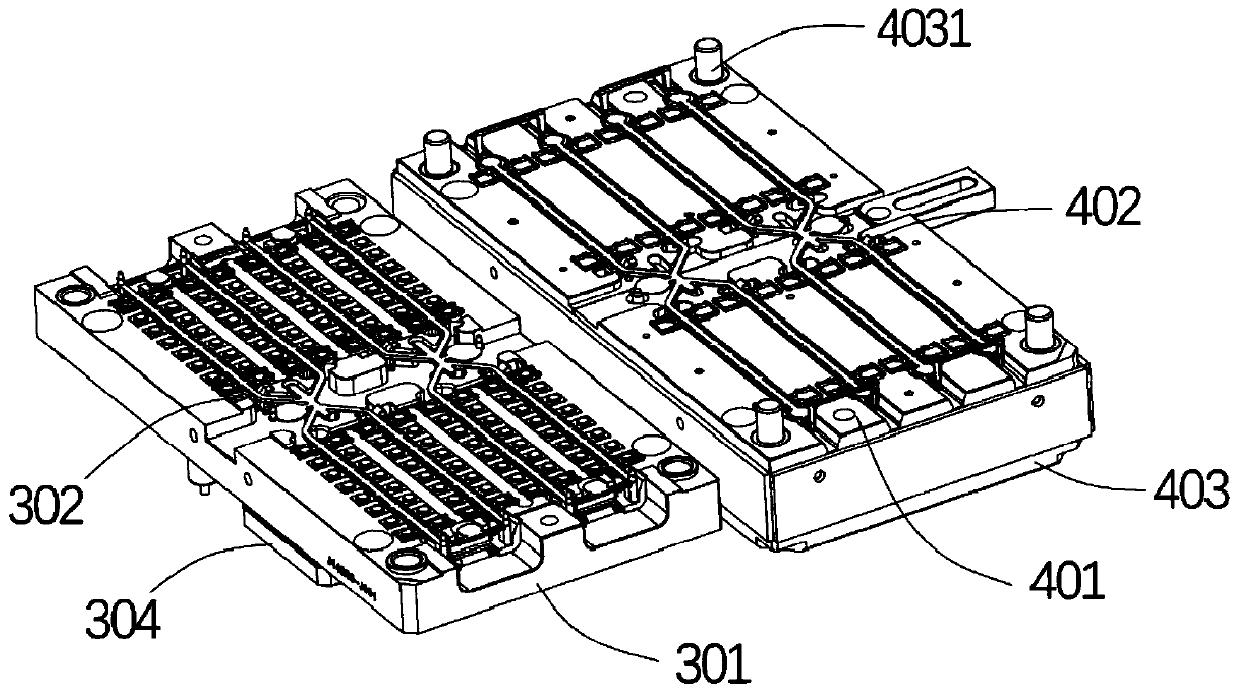

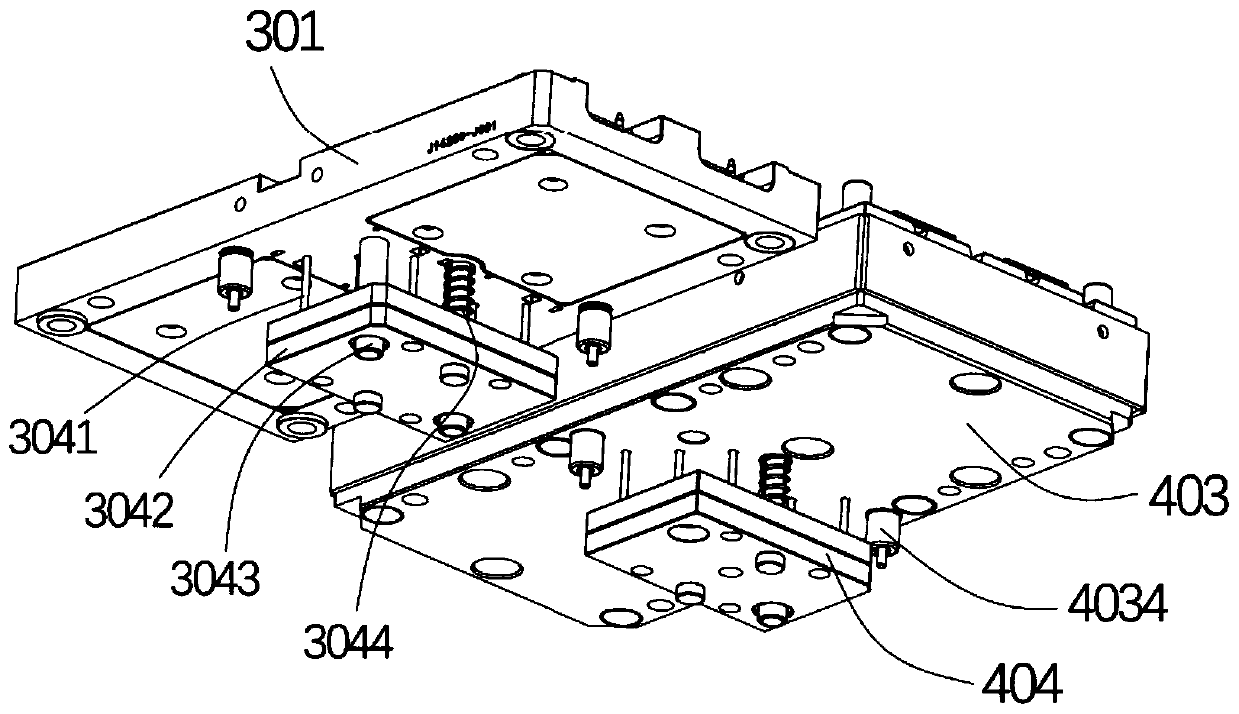

[0041] Such as Figure 4 , Figure 5 As shown, the scissor legs are made of plastic injection molding. In order to improve the production efficiency during injection molding, the inner parts of the scissor legs and the outer frame of the scissor legs are injected several times at one time. In order to facilitate assembly and moving, the injection molded parts It is made of a lot of scissor foot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com