Preparation method of high-porosity polyolefin lithium-ion battery diaphragm

A lithium-ion battery, high-porosity technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as inability to achieve effects, and achieve the effects of excellent high-temperature thermal shrinkage, easy control of conditions, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

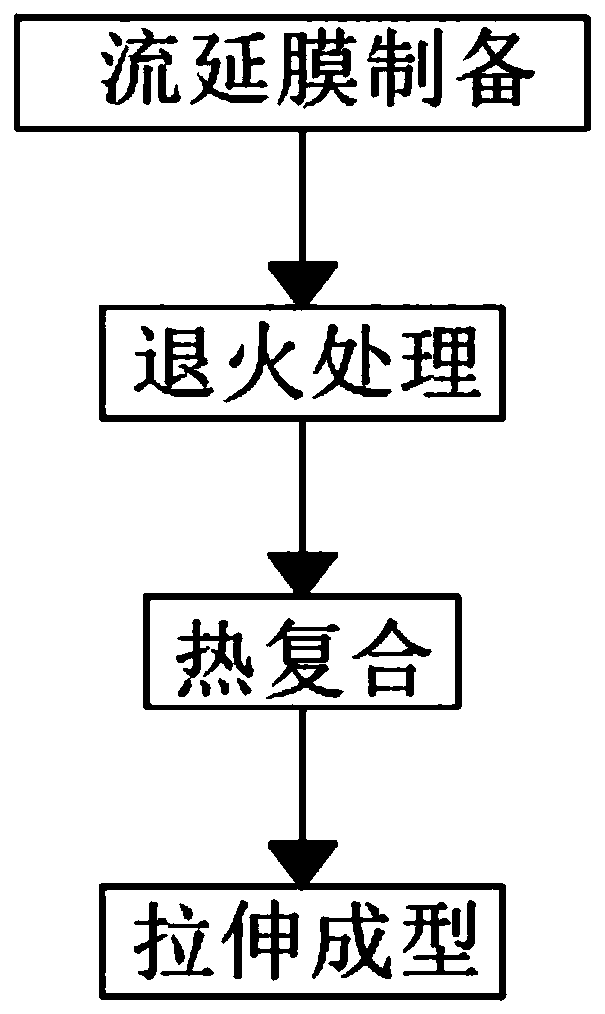

[0032] A method for preparing a high-porosity polyolefin lithium-ion battery diaphragm, comprising casting film preparation-annealing treatment-thermal compounding-stretch setting:

[0033] ①Preparation of cast film: put polypropylene granules into the production extrusion system with extruder temperature of 220°C, runner temperature of 225°C, die temperature of 210°C, cast sheet temperature of 90°C and production speed of 90m / min Extrusion is carried out, and then monolayer cast film is collected;

[0034] ②Annealing treatment: put the prepared single-layer cast film into an annealing device for annealing treatment with an annealing temperature of 110°C and annealing time of 12 hours;

[0035] ③ Thermal lamination: superimpose the single-layer cast film after annealing treatment, so that the cast film with two superimposed layers is put into the lamination device for thermal lamination treatment at a lamination temperature of 80°C to obtain a lamination film;

[0036] ④ Stre...

Embodiment example 2

[0038] A method for preparing a high-porosity polyolefin lithium-ion battery diaphragm, comprising casting film preparation-annealing treatment-thermal compounding-stretch setting:

[0039] ①Preparation of cast film: put polypropylene granules into the production extrusion system with extruder temperature of 230°C, runner temperature of 225°C, die temperature of 210°C, cast sheet temperature of 100°C and production speed of 90m / min Extrusion is carried out, and then monolayer cast film is collected;

[0040] ②Annealing treatment: Put the prepared single-layer cast film into an annealing device for annealing treatment with an annealing temperature of 120°C and annealing time of 18 hours;

[0041] ③ Thermal lamination: superimpose the single-layer cast film after annealing treatment, so that the cast film with two superimposed layers is put into the lamination device for thermal lamination treatment at a lamination temperature of 80°C to obtain a lamination film;

[0042] ④ Str...

Embodiment example 3

[0044] A method for preparing a high-porosity polyolefin lithium-ion battery diaphragm, comprising casting film preparation-annealing treatment-thermal compounding-stretch setting:

[0045] ①Preparation of cast film: put polypropylene pellets into the production extrusion system with extruder temperature of 225°C, runner temperature of 225°C, die head temperature of 210°C, cast sheet temperature of 95°C and production speed of 90m / min Extrusion is carried out, and then monolayer cast film is collected;

[0046] ②Annealing treatment: Put the prepared single-layer cast film into an annealing device for annealing treatment with an annealing temperature of 115°C and annealing time of 15h;

[0047] ③ Thermal lamination: superimpose the single-layer cast film after annealing treatment, so that the cast film with two superimposed layers is put into the lamination device for thermal lamination treatment at a lamination temperature of 80°C to obtain a lamination film;

[0048] ④ Stret...

PUM

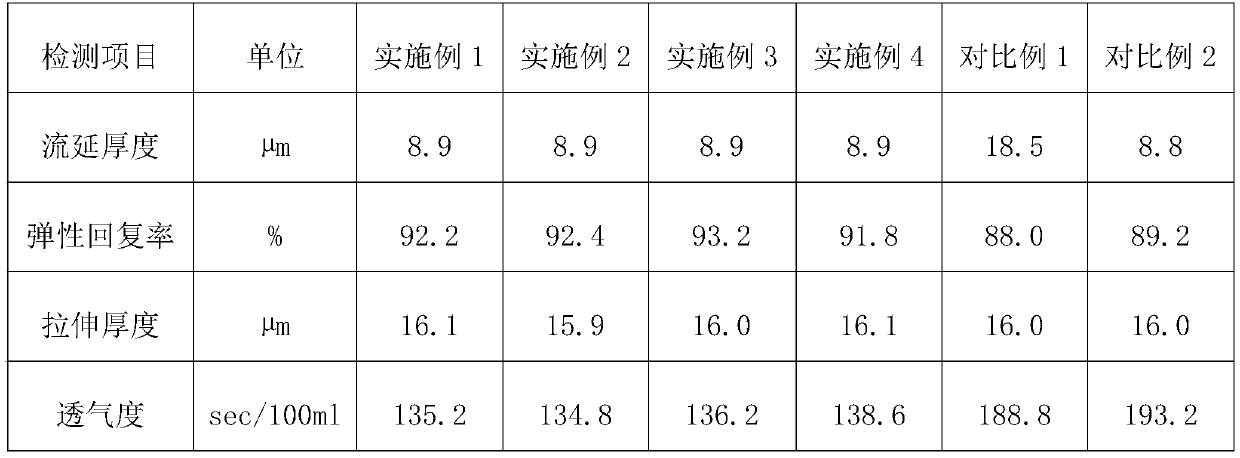

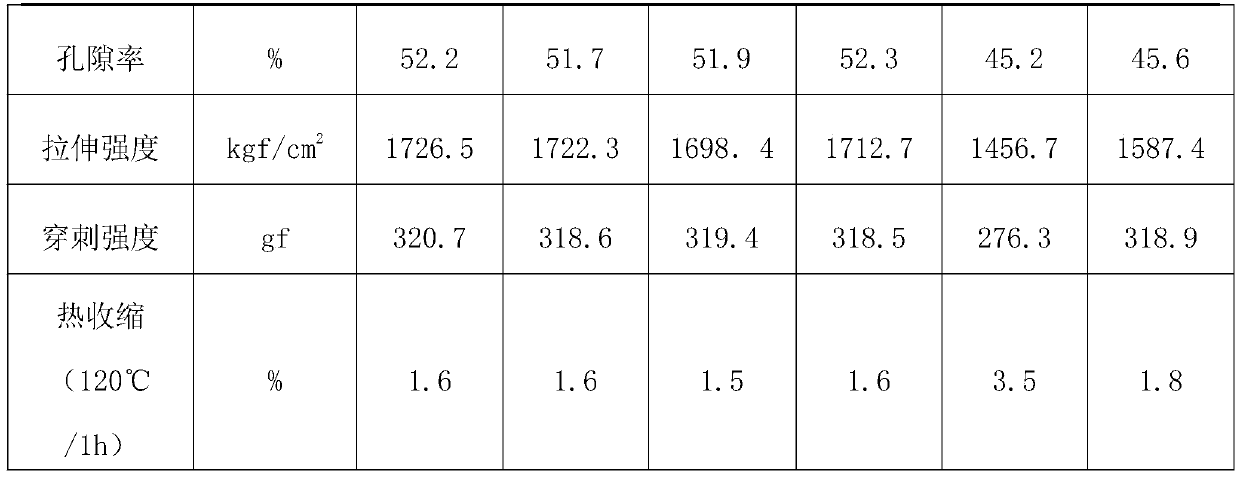

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com