Double-layer tablet press and method for preparing double-layer tablets by adopting double-layer tablet press

A double-layer tablet and tablet press technology, which is applied to presses, material forming presses, manufacturing tools, etc., can solve the problems affecting the production efficiency of double-layer tablets, cumbersome operation procedures, and collisions with metering tracks, so as to avoid tablet The effect of reducing the weight of the agent, improving production efficiency, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

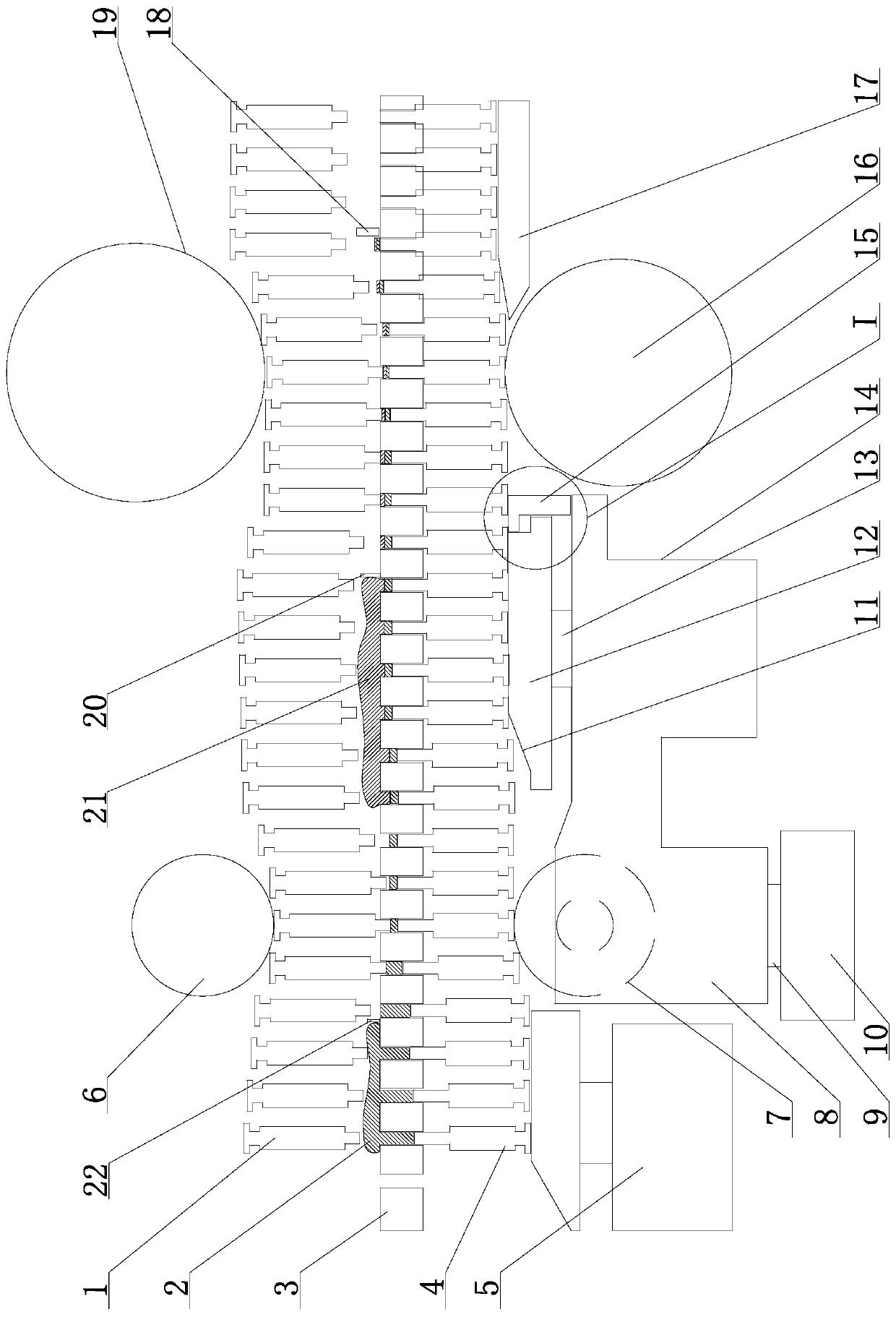

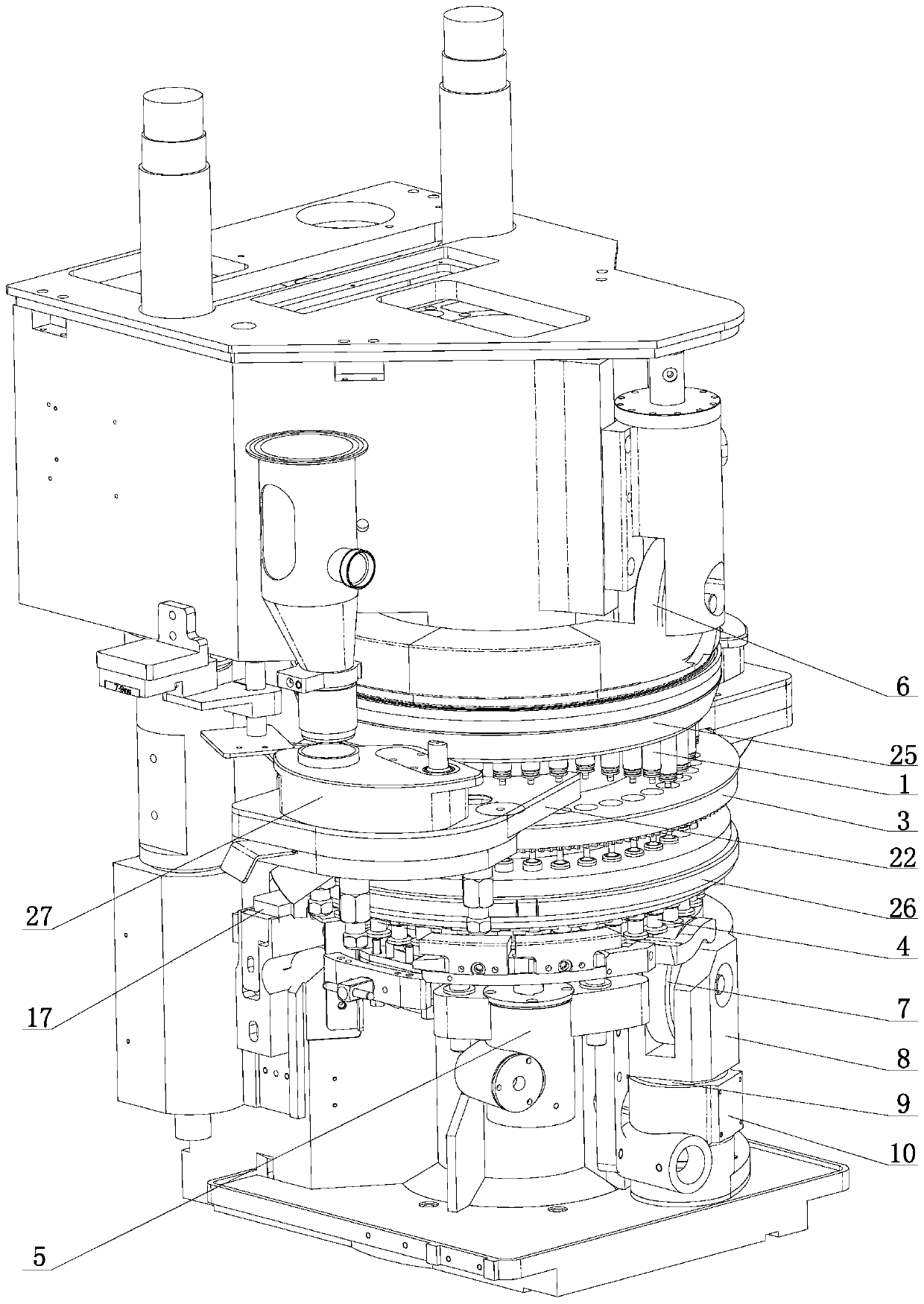

[0030] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

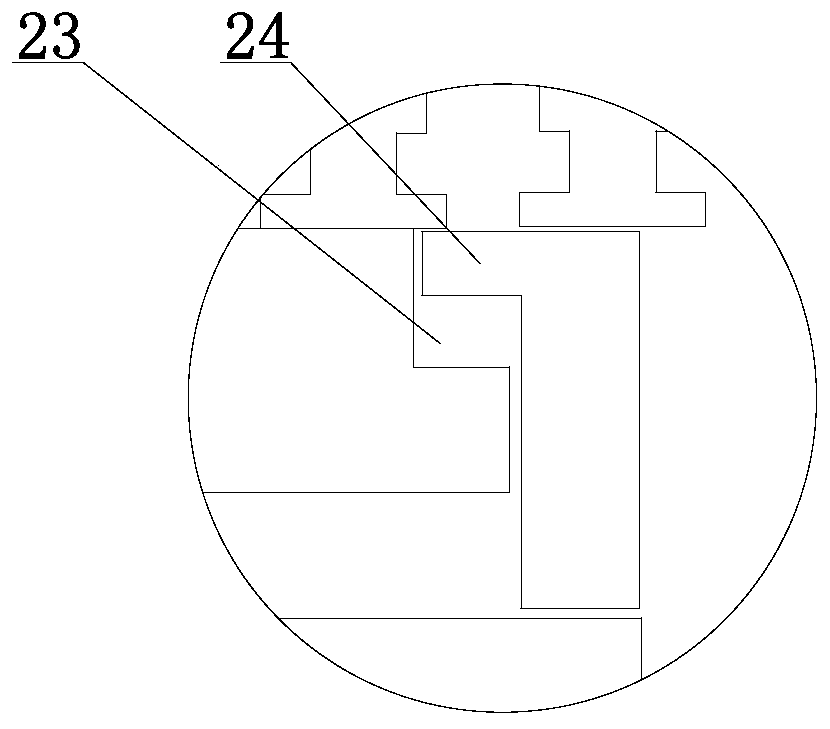

[0031] like Figures 1 to 5 As shown, the double-layer tablet press includes a first-layer metering assembly 5, a first-layer pre-compression assembly, and a second-layer metering assembly arranged in sequence; the first-layer pre-compression assembly includes a pre-compression cylinder, an upper pre-compression wheel 6 and the lower pre-pressing wheel 7, the piston rod 9 of the pre-pressing cylinder faces downward and is connected to the adjustment base 10 below it, and the lower pre-pressing wheel 7 is installed on the pre-pressing cylinder cylinder 8; the second-layer metering assembly includes the metering track 12 and The metering cylinder, the end of the piston rod 13 of the metering cylinder is connected to the metering track 12, and the end of the metering track 12 near the lower pre-pressing wheel has an inclined guide table 11; The metering cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com