A multi-vehicle flexible transfer system and its working method

A transfer system and flexible technology, applied in the direction of rollers, mechanical conveyors, conveyor objects, etc., can solve problems such as the inability to meet the requirements of collinear conveying, and achieve the effect of high degree of automation, reduction of production costs, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

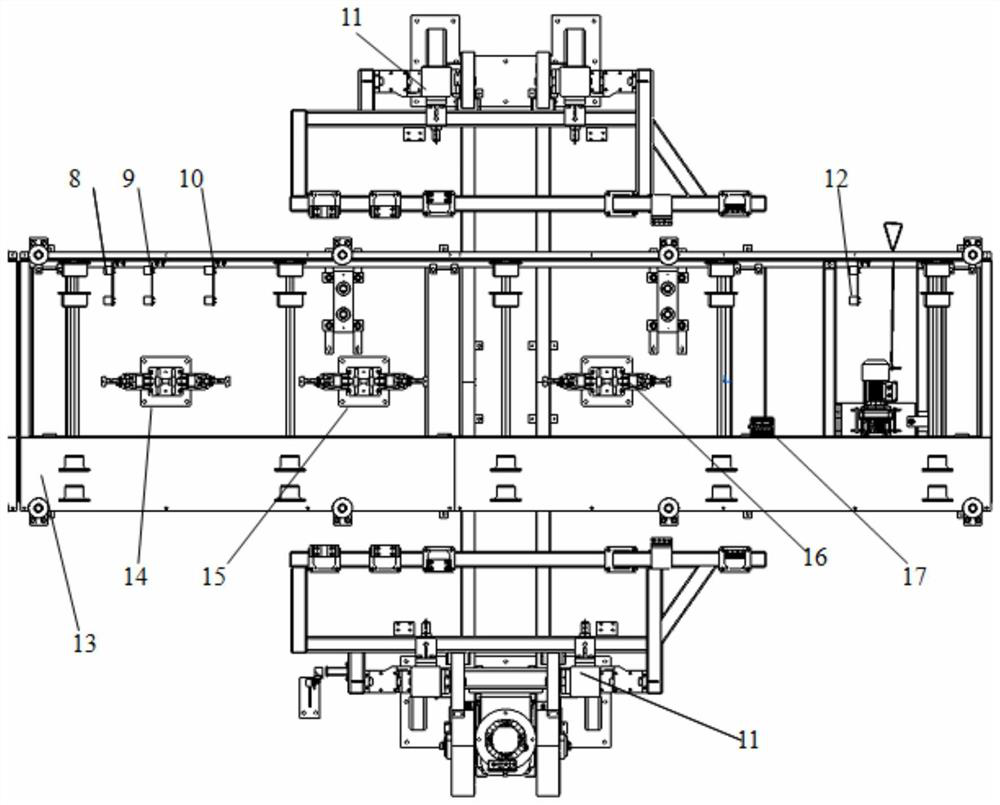

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing and a specific embodiment, and its content is explanation of the present invention rather than limitation:

[0034] According to the planning and process requirements of new products of a certain car model, it is necessary to realize the collinear conveying of new and old products, and meet the collinear conveying of 4 types of vehicle body-in-white. The four types of longitudinal beams are as follows: Figure 7 , where the floor is divided into flat floor and high-low floor. The high-low floor is divided into two height differences of 120mm and 255mm, and three lengths of 1700mm, 2000mm and 2300mm, as shown in the following table:

[0035] car model height difference length Model A 0 1700 Model B 120 2000 Model C 120 2300 Model D 255 2300

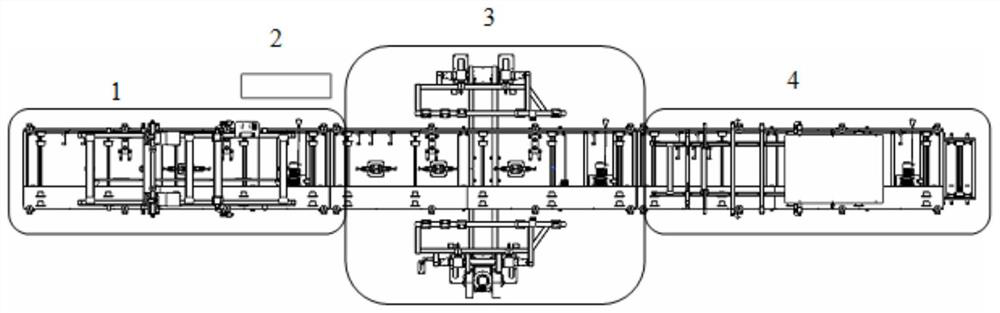

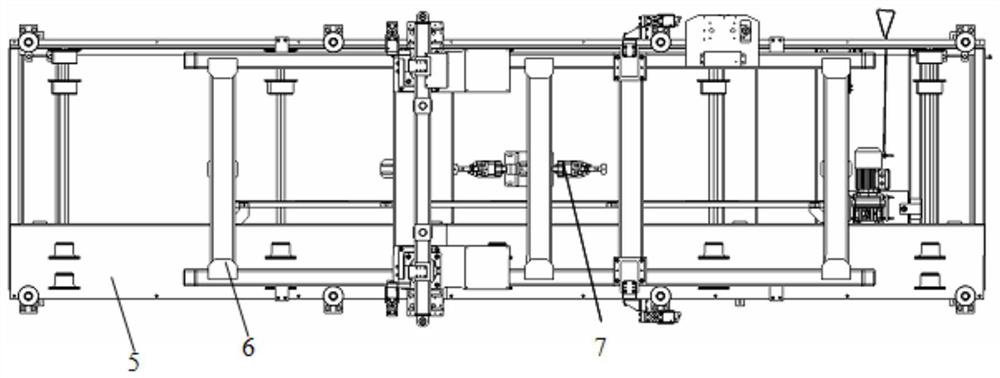

[0036] Such as figure 1 , is a multi-vehicle flexible transfer system of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com