Making method of super soft cotton woven fabric

A manufacturing method and fabric technology, applied in the processing of textile materials, continuous processing of textile materials, textiles and papermaking, etc., can solve the problems of hard hand feeling, stiff hand feel of fabrics, and stiff hand feel of cotton fabrics, so as to improve softness , the effect of saving steam energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

[0024] Traditional cotton woven fabrics go through multiple wet treatment processes during the dyeing and finishing process, such as pre-treatment, mercerizing, dyeing, washing, etc. In these processes, the woven fabrics need to be dried with a drying cylinder. Then improve the fabric feel by adding some softener. In the above-mentioned manufacturing process, the woven fabric will become stiffer after repeated wetting and drying; if the general softener is only added to improve it, the improvement effect is not very satisfactory, and the softener will be washed after washing. When it falls off, the woven fabric gradually becomes stiff again.

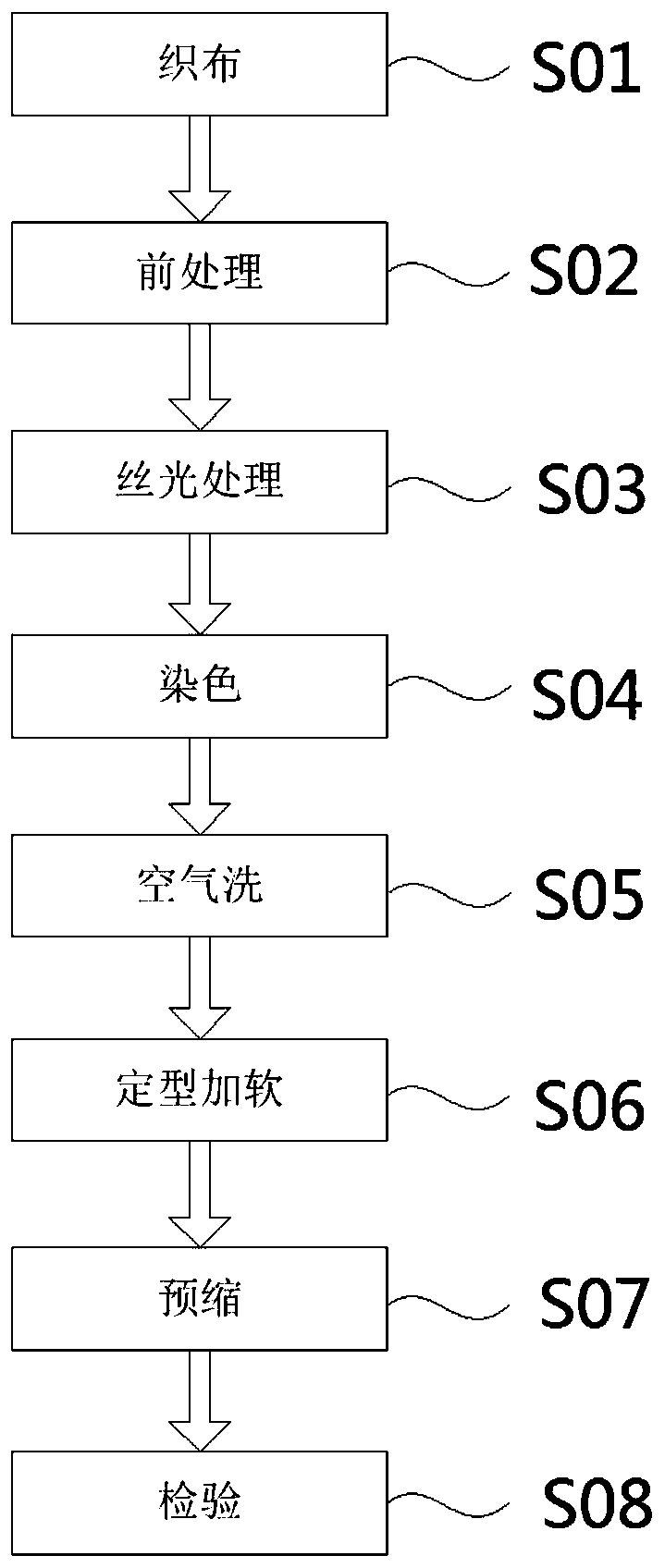

[0025] A kind of manufacture method of super soft cotton woven fabric of the present application, such as figure 1 As shown, the process steps are as follows:

[0026] S01: Weaving

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com