Green light induction controlled hydrophilic/hydrophobic intelligent surface material and preparation method and application thereof

A surface material and hydrophilic technology, applied in the field of photosensitive materials, can solve the problems of photosensitive molecular bleaching on the surface of materials, restricting materials, etc., and achieve the effect of expanding the potential of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

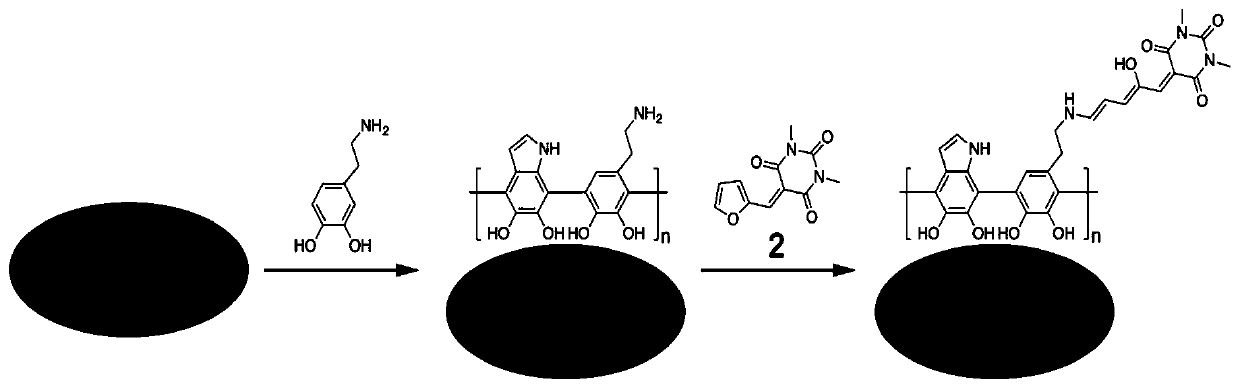

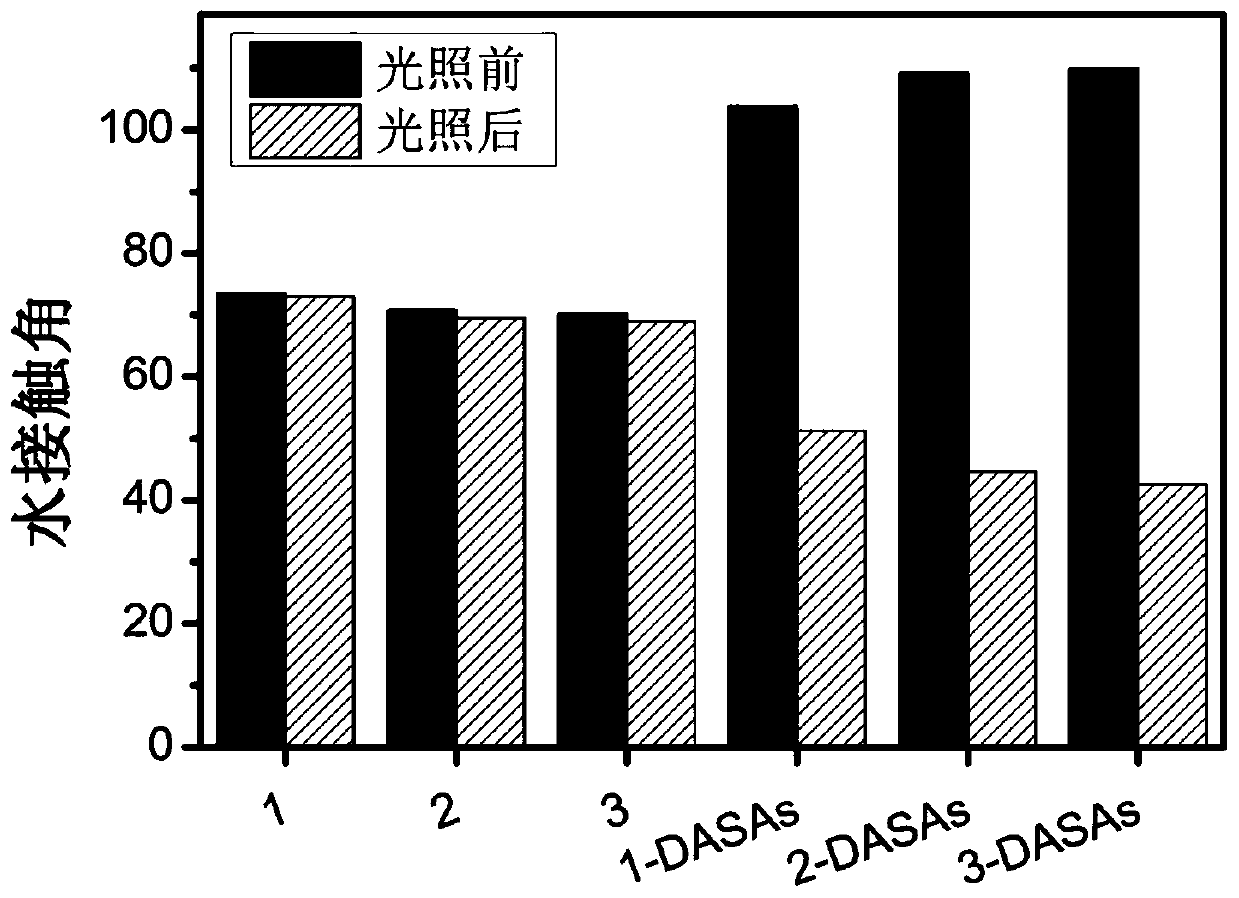

[0038] A preferred embodiment of the present invention provides a method for preparing a hydrophilic / hydrophobic smart surface material induced and controlled by green light. The specific preparation steps are as follows:

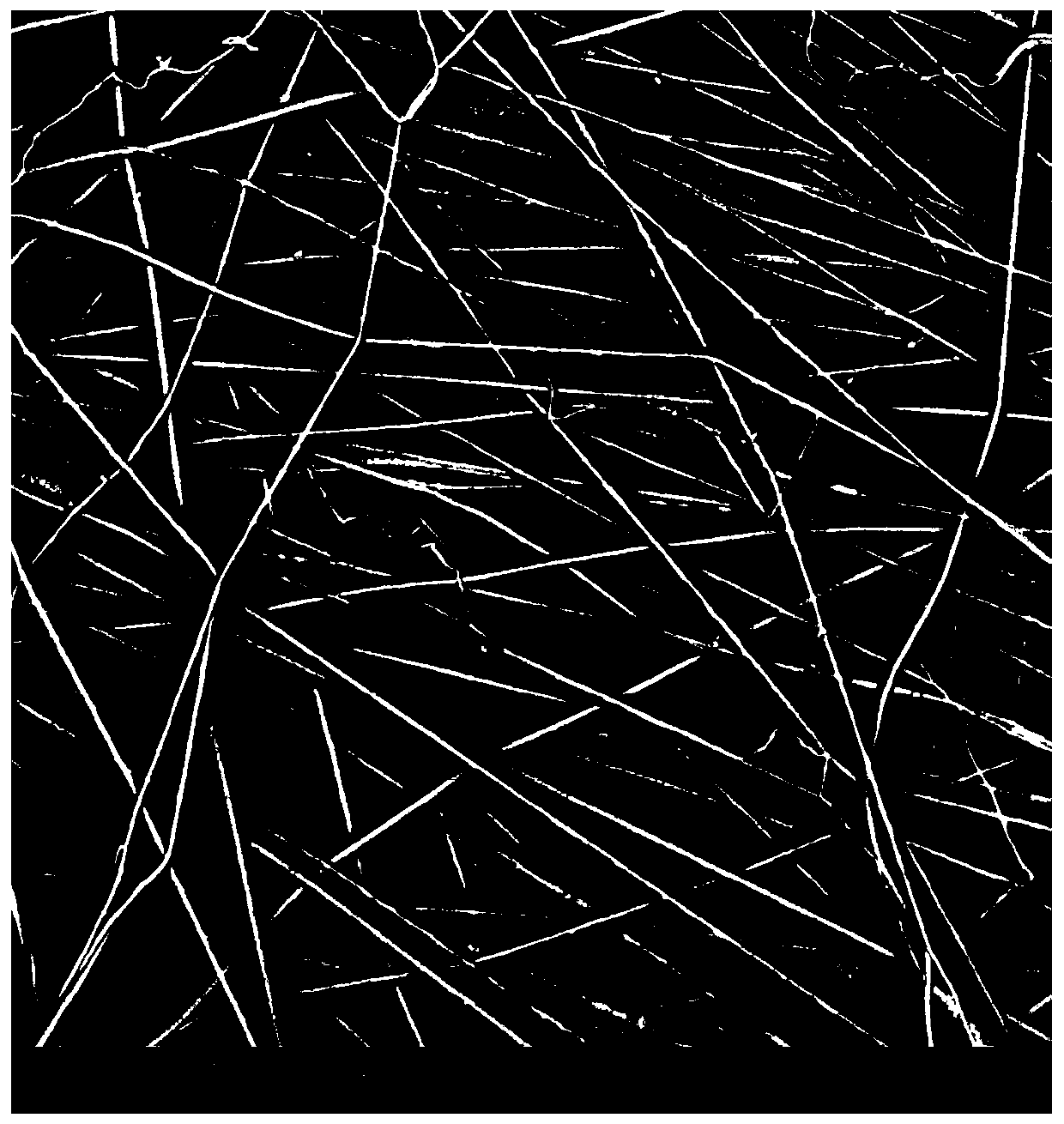

[0039]Using N-methylpyrrolidone as the solvent and polycaprolactone with a concentration of 10wt% as the substrate, the nanofiber substrate was prepared by electrospinning. The electrospinning voltage was 15kV, the receiving plate distance was 16cm, and the injection speed was is 15mL / h; the dopamine is polymerized and coated on the surface of the nanofiber substrate, and a dopamine solution is first prepared, using tris buffer (tris buffer, pH=8.5) as a solvent, and the dopamine concentration is 5mg / mL, and then In turn, add copper sulfate pentahydrate at a concentration of 0.5 mg / mL and hydrogen peroxide at a concentration of 0.5 mg / mL to the dopamine solution at a mass ratio of 1:1. The mass ratio of dopamine to copper sulfate pentahydrate is 10:1. The c...

Embodiment 2

[0042] A preferred embodiment of the present invention provides a method for preparing a hydrophilic / hydrophobic smart surface material induced and controlled by green light. The specific preparation steps are as follows:

[0043] Using N-methylpyrrolidone as the solvent and polycaprolactone with a concentration of 12wt% as the substrate, the nanofiber substrate was prepared by electrospinning. The electrospinning voltage was 15kV, the receiving plate distance was 16cm, and the injection speed was is 15mL / h; the dopamine is polymerized and coated on the surface of the nanofiber substrate, and a dopamine solution is first prepared, using tris buffer (tris buffer, pH=8.5) as a solvent, and the dopamine concentration is 5mg / mL, and then In turn, add copper sulfate pentahydrate at a concentration of 0.5 mg / mL and hydrogen peroxide at a concentration of 0.5 mg / mL to the dopamine solution at a mass ratio of 1:1. The mass ratio of dopamine to copper sulfate pentahydrate is 10:1. The ...

Embodiment 3

[0046] A preferred embodiment of the present invention provides a method for preparing a hydrophilic / hydrophobic smart surface material induced and controlled by green light. The specific preparation steps are as follows:

[0047] Using N-methylpyrrolidone as the solvent and polycaprolactone with a concentration of 14wt% as the substrate, the nanofiber substrate was prepared by electrospinning. The electrospinning voltage was 15kV, the receiving plate distance was 16cm, and the injection speed was is 15mL / h; the dopamine is polymerized and coated on the surface of the nanofiber substrate, and a dopamine solution is first prepared, using tris buffer (tris buffer, pH=8.5) as a solvent, and the dopamine concentration is 5mg / mL, and then In turn, add copper sulfate pentahydrate at a concentration of 0.5 mg / mL and hydrogen peroxide at a concentration of 0.5 mg / mL to the dopamine solution at a mass ratio of 1:1. The mass ratio of dopamine to copper sulfate pentahydrate is 10:1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com