Green light-induced controlled hydrophilic/hydrophobic smart surface materials and their preparation methods and applications

A surface material and hydrophilic technology, applied in the field of light-sensitive materials, can solve the problems of bleaching of light-sensitive molecules on the surface of materials, limiting materials, etc., and achieve the effect of expanding the potential of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

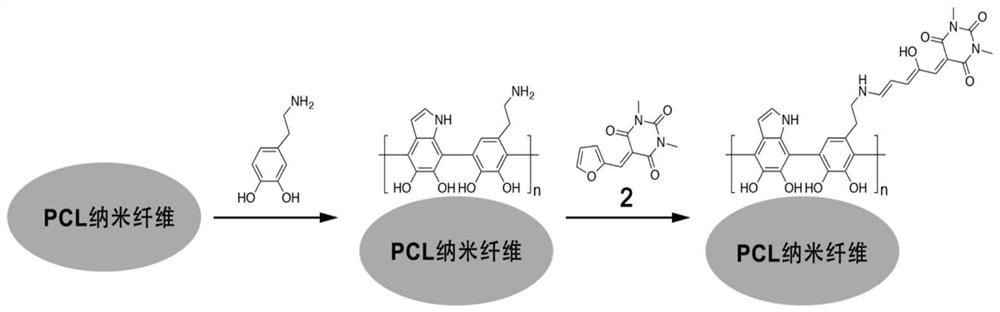

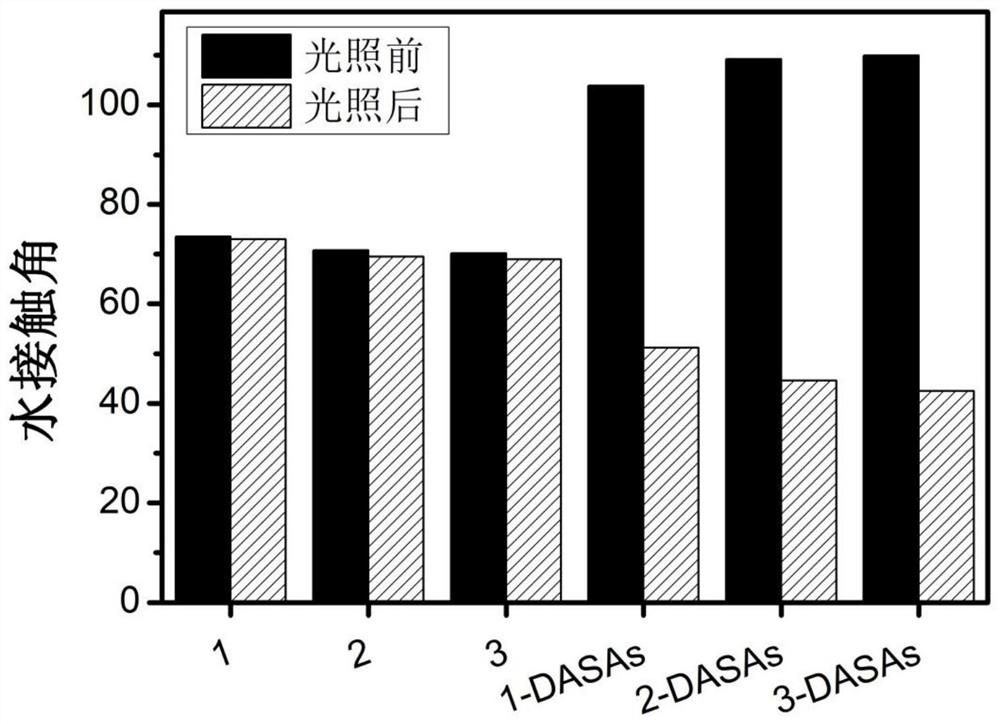

[0038] A preferred embodiment of the present invention provides a method for preparing a hydrophilic / hydrophobic smart surface material induced and controlled by green light. The specific preparation steps are as follows:

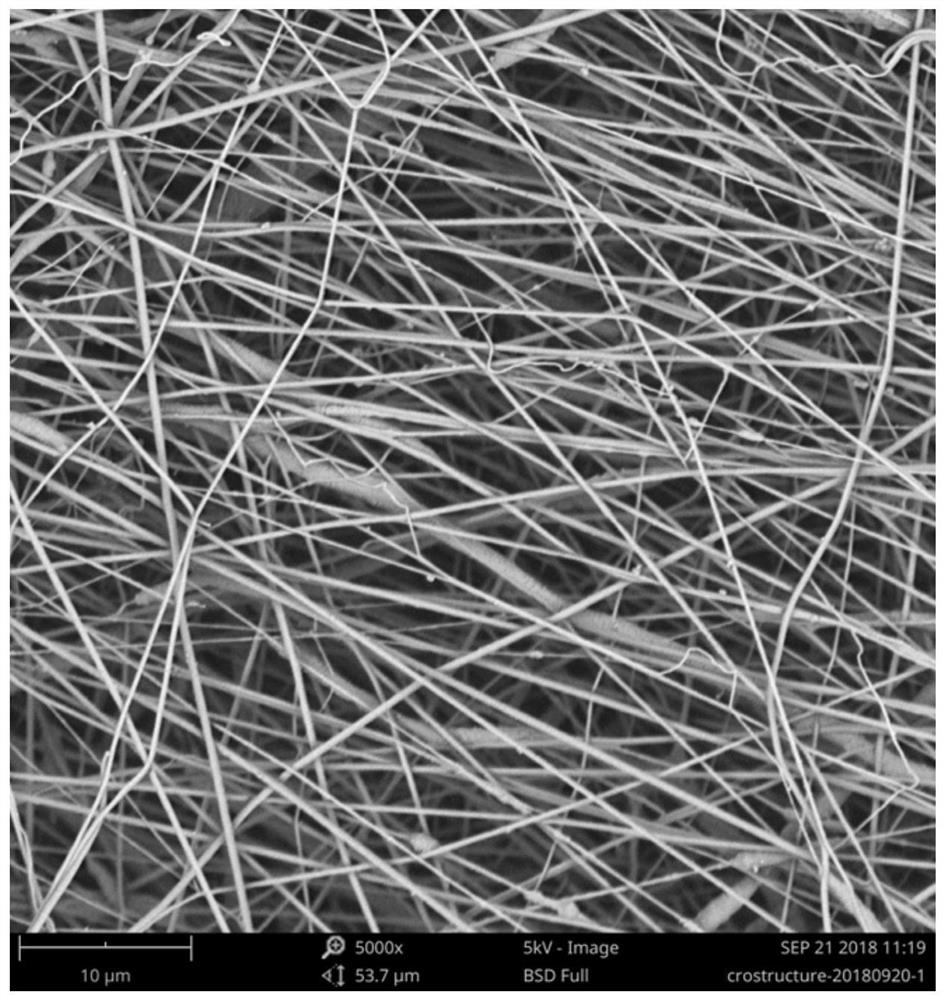

[0039]Using N-methylpyrrolidone as the solvent and polycaprolactone with a concentration of 10wt% as the substrate, the nanofiber substrate was prepared by electrospinning. The electrospinning voltage was 15kV, the receiving plate distance was 16cm, and the injection speed was is 15mL / h; the dopamine is polymerized and coated on the surface of the nanofiber substrate, and a dopamine solution is first prepared, using tris buffer (tris buffer, pH=8.5) as a solvent, and the dopamine concentration is 5mg / mL, and then In turn, add copper sulfate pentahydrate at a concentration of 0.5 mg / mL and hydrogen peroxide at a concentration of 0.5 mg / mL to the dopamine solution at a mass ratio of 1:1. The mass ratio of dopamine to copper sulfate pentahydrate is 10:1. The c...

Embodiment 2

[0042] A preferred embodiment of the present invention provides a method for preparing a hydrophilic / hydrophobic smart surface material induced and controlled by green light. The specific preparation steps are as follows:

[0043] Using N-methylpyrrolidone as the solvent and polycaprolactone with a concentration of 12wt% as the substrate, the nanofiber substrate was prepared by electrospinning. The electrospinning voltage was 15kV, the receiving plate distance was 16cm, and the injection speed was is 15mL / h; the dopamine is polymerized and coated on the surface of the nanofiber substrate, and a dopamine solution is first prepared, using tris buffer (tris buffer, pH=8.5) as a solvent, and the dopamine concentration is 5mg / mL, and then In turn, add copper sulfate pentahydrate at a concentration of 0.5 mg / mL and hydrogen peroxide at a concentration of 0.5 mg / mL to the dopamine solution at a mass ratio of 1:1. The mass ratio of dopamine to copper sulfate pentahydrate is 10:1. The ...

Embodiment 3

[0046] A preferred embodiment of the present invention provides a method for preparing a hydrophilic / hydrophobic smart surface material induced and controlled by green light. The specific preparation steps are as follows:

[0047] Using N-methylpyrrolidone as the solvent and polycaprolactone with a concentration of 14wt% as the substrate, the nanofiber substrate was prepared by electrospinning. The electrospinning voltage was 15kV, the receiving plate distance was 16cm, and the injection speed was is 15mL / h; the dopamine is polymerized and coated on the surface of the nanofiber substrate, and a dopamine solution is first prepared, using tris buffer (tris buffer, pH=8.5) as a solvent, and the dopamine concentration is 5mg / mL, and then In turn, add copper sulfate pentahydrate at a concentration of 0.5 mg / mL and hydrogen peroxide at a concentration of 0.5 mg / mL to the dopamine solution at a mass ratio of 1:1. The mass ratio of dopamine to copper sulfate pentahydrate is 10:1. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com