Closestool flushing mechanism and flushing control method thereof

A control method and toilet technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve the problems of high water supply requirements in pipelines and affect the life of flushing components, etc., achieve simple structure, ensure flushing effect, and realize flushing of large and small rows Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

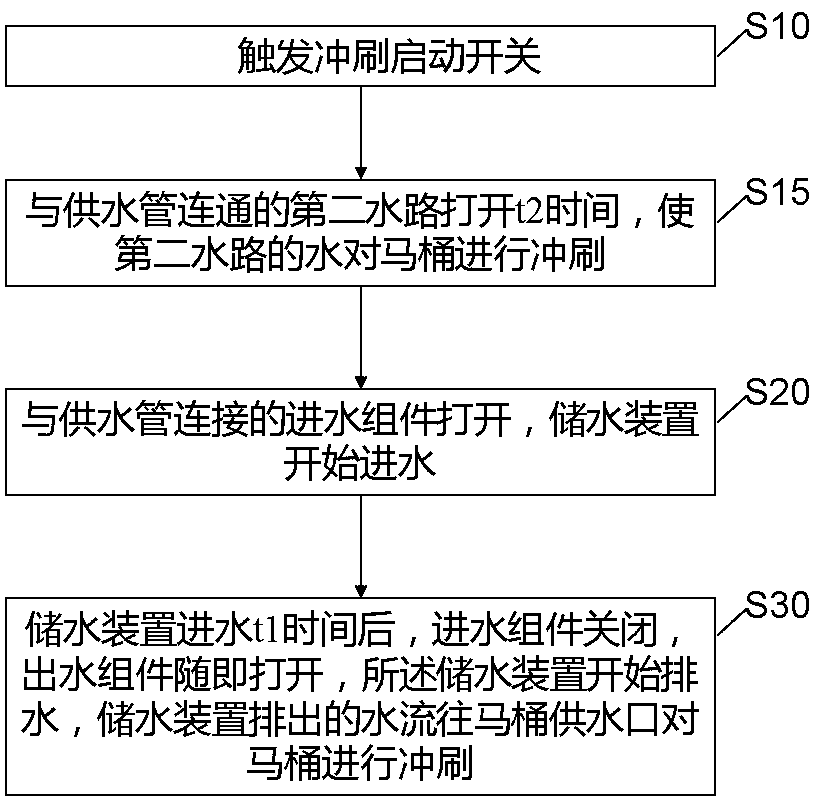

Method used

Image

Examples

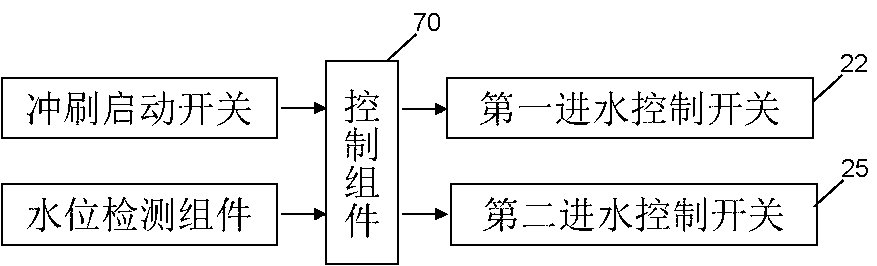

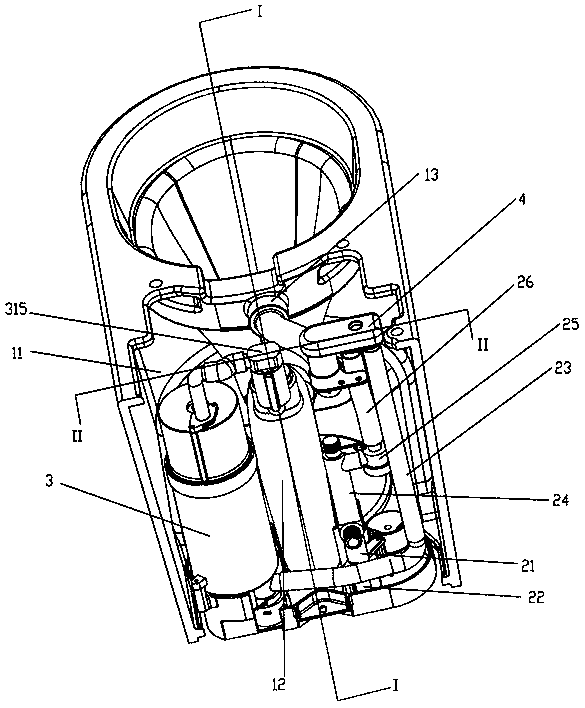

Embodiment 1

[0044] Such as figure 1 As shown, in the application state, the flushing mechanism is installed in the accommodating space 11 at the rear of the toilet 1, and the flushing mechanism includes a first water inlet pipe 21, a first water inlet control switch 22, and a first water outlet pipe 23; The first water inlet control switch 22 is connected to the water supply source through the first water inlet pipe 21. The water inlet assembly 35 is provided with a water inlet 351, and the water outlet assembly 36 is provided with a water outlet 361. The first water inlet control switch 22 is connected to the storage tank. The water inlet 351 of the water device 3 is connected, and the water outlet 361 of the water storage device 3 is connected with the water supply port 13 of the toilet through the first water outlet pipe 23 for flushing the toilet. The flush mechanism also has a second waterway, which includes a second water inlet pipe 24, a second water inlet control switch 25 and a s...

Embodiment 2

[0062] The difference between this embodiment and the first embodiment is that: the water outlet assembly 36 also uses a water outlet control switch 60 communicatively connected with the control assembly 70 to control water outlet, and the water outlet control switch 60 is preferably a solenoid valve. Therefore, the linkage control between the water inlet component and the water outlet component is realized through electronic control, that is, the control logic of the control component 70 is: when the first water inlet control switch 22 is turned on, the water outlet control switch 60 is turned off; the first water inlet control switch 22 When closed, the water outlet control switch 60 is opened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com