Construction method of high-precision formwork for cast-in-place fair-faced concrete in wind tunnel

A technology of fair-faced concrete and construction methods, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problems of low precision of fair-faced concrete, Achieve the effects of various measurement and control methods, high dimensional accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

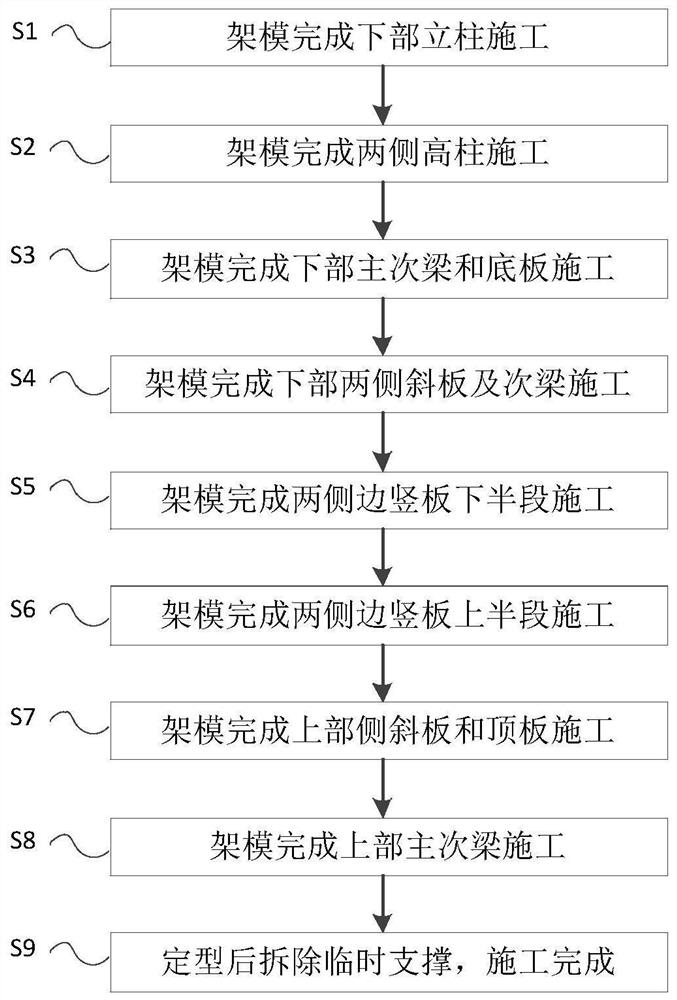

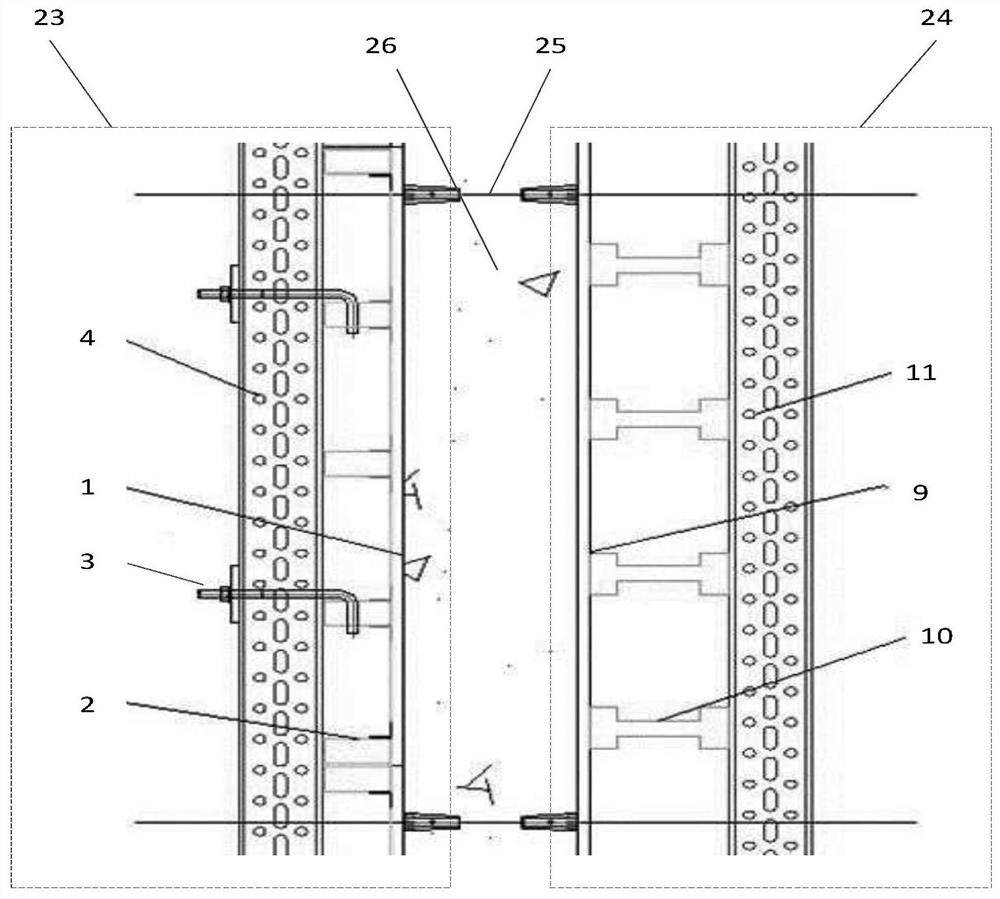

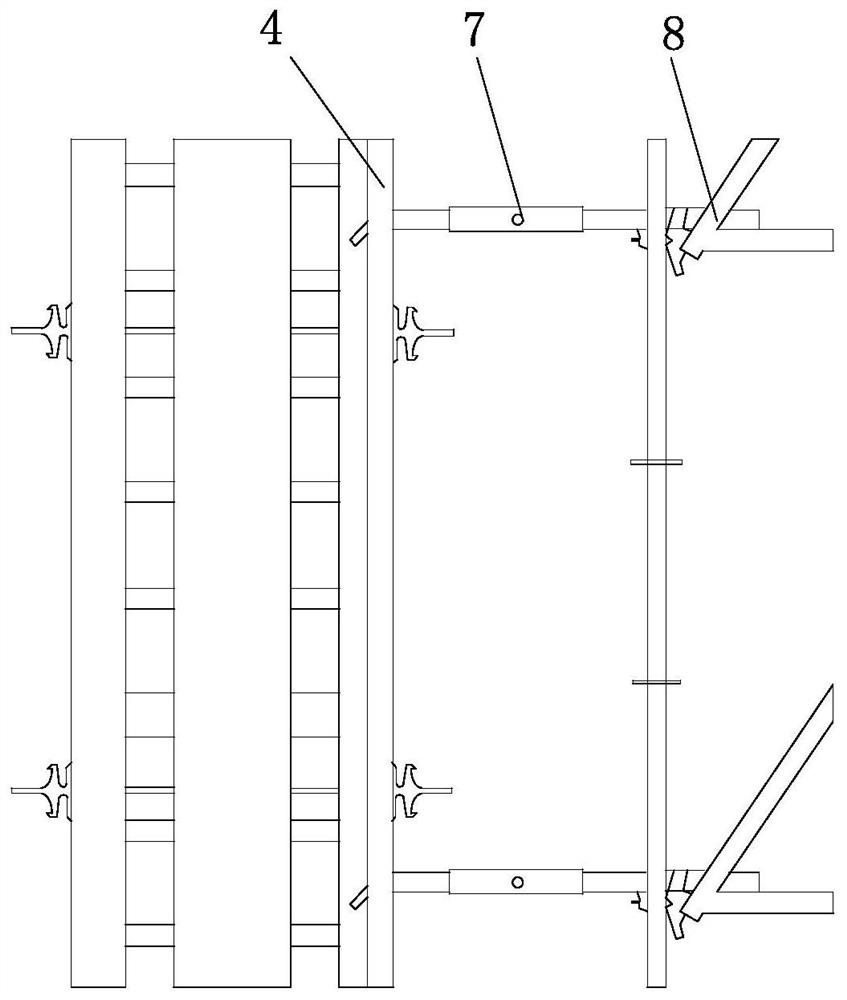

[0041] Such as figure 1 and Figure 8 As shown, the high-precision formwork construction method of cast-in-place concrete wind tunnel requires the formwork to be processed to meet the high-precision requirements. , so that all formworks with the same purpose (vertical, horizontal, and inclined) are kept at the same height, so that the formwork can be realized more accurately, and the flatness of the formwork can be adjusted so that the entire surface in contact with the concrete The inner surface is horizontal.

[0042] During specific construction:

[0043] Step 1: Use the cut formwork to set up the formwork at the determined position where the wind tunnel needs to be poured to pour the lower columns of the entire wind tunnel structure, where the number of lower columns is at least six, and all the lower columns are in two columns The distribution and simultaneous positions correspond to each other (six times, that is, they are divided into two columns, and the columns are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com