New calibration method of lysimeter weighing system

A technology of weighing system and calibration method, which is applied in the new calibration field of lysimeter weighing system, can solve the problems such as the increase of error value, achieve the effect of increasing accuracy, reducing error rate and error value, and improving contradiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A new calibration method for a weighing system of a lysimeter, comprising the following steps:

[0042] 1) Adopt static calibration method

[0043] ① Zero point calibration: do not add weights, wait until the weighing system of the lysimeter is in a stable state, and perform zero point calibration.

[0044] ②Repeated calibration: starting from the smallest weight, place the weight of each specification 5 times to measure 5 values, and finally take the average value.

[0045] ③Linear calibration: starting from the smallest weight, place weights of 200g, 300g, 500g, 700g, 900g, 1000g, 2000g, etc. for linear calibration, repeat the array, and take the average value to make a linear graph.

[0046] ④Maximum capacity calibration: place weights according to the required maximum capacity.

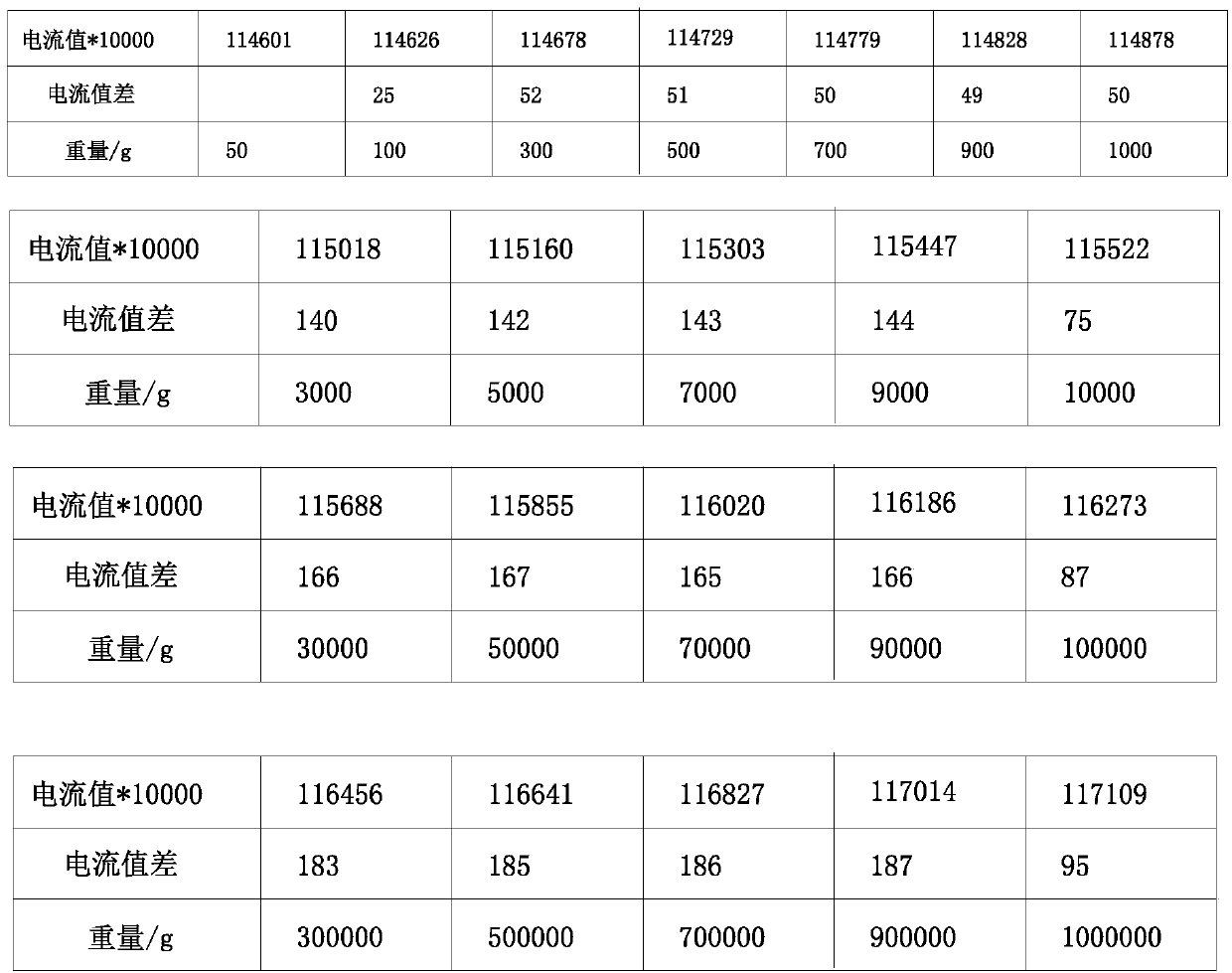

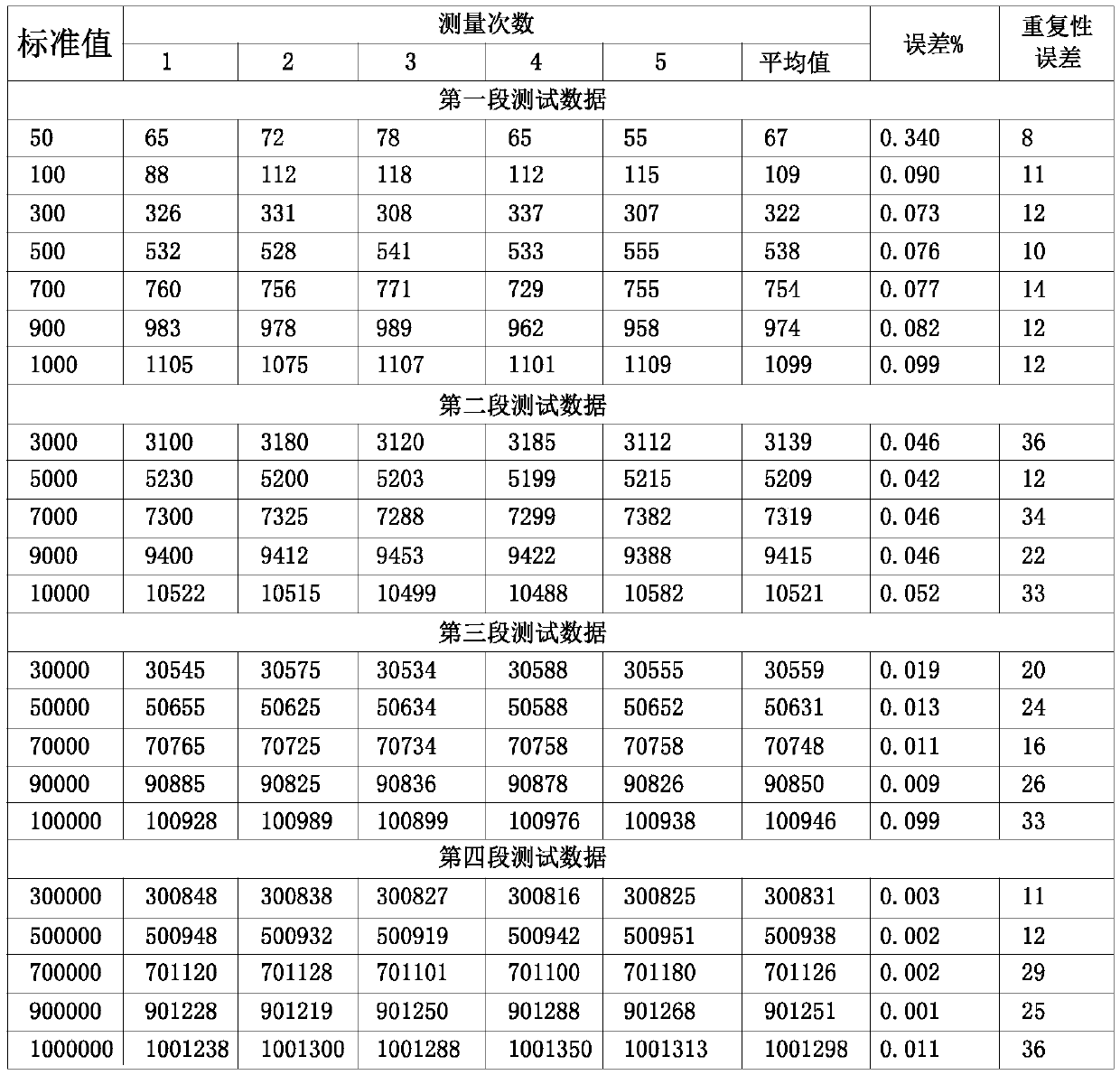

[0047] ⑤ Calibration result inspection: place weights in order, repeat multiple groups and record the value as figure 1 shown in the four tables.

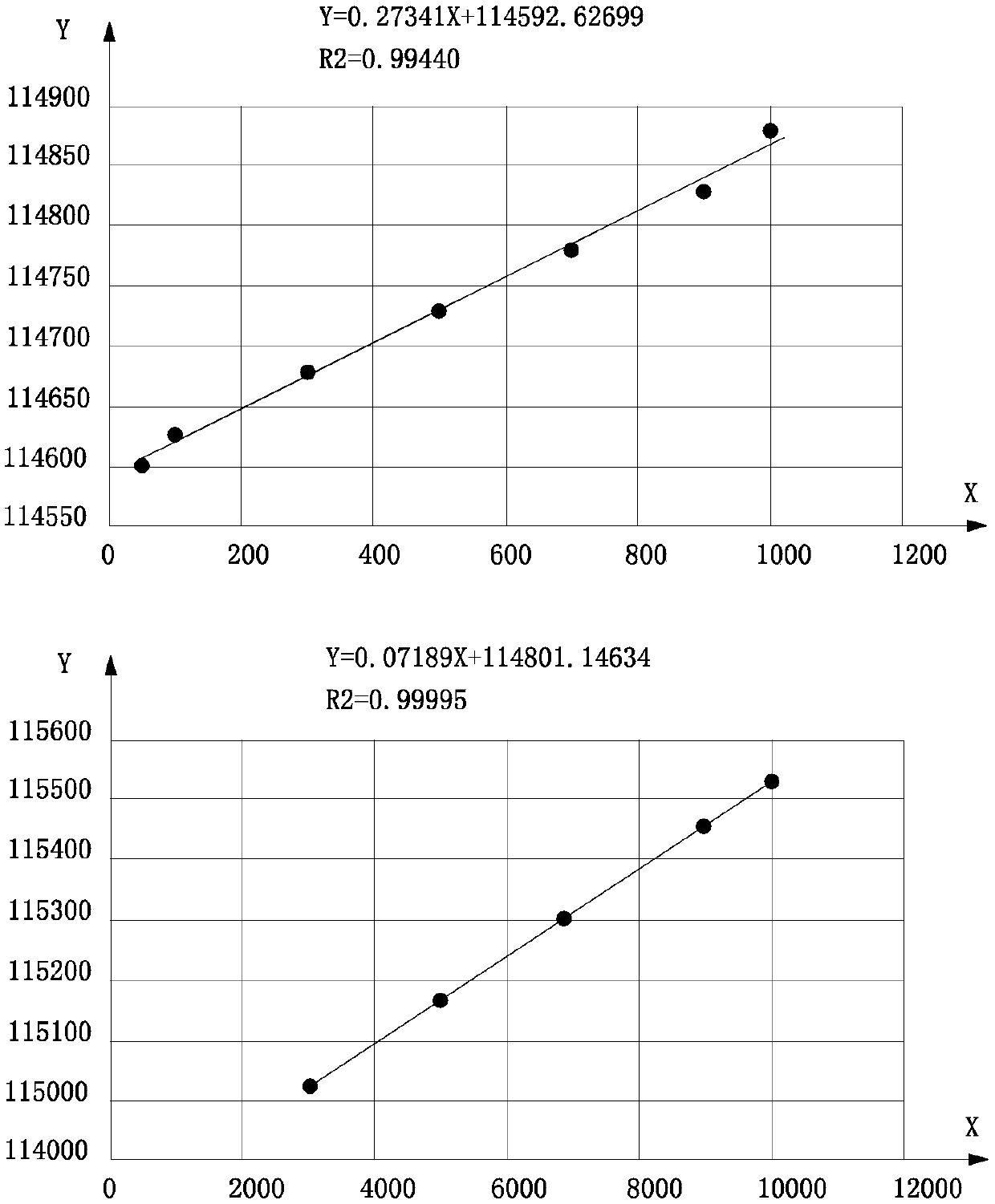

[0048] 2) Fit a straight line accordi...

Embodiment 2

[0055] A new calibration method for a weighing system of a lysimeter, comprising the following steps:

[0056] 1) Adopt static calibration method

[0057] ① Zero point calibration: do not add weights, wait until the weighing system of the lysimeter is in a stable state, and perform zero point calibration.

[0058] ②Repeated calibration: starting from the smallest weight, place the weight of each specification 5 times to measure 5 values, and finally take the average value.

[0059] ③Linear calibration: starting from the smallest weight, place weights of 200g, 300g, 500g, 700g, 900g, 1000g, 2000g, etc. for linear calibration, repeat the array, and take the average value to make a linear graph.

[0060] ④Maximum capacity calibration: place weights according to the required maximum capacity.

[0061] ⑤ Calibration result inspection: place weights in order, repeat multiple groups and record the value as figure 1 shown in the four tables.

[0062] 2) Fit a straight line accordi...

Embodiment 3

[0069] A new calibration method for a weighing system of a lysimeter, comprising the following steps:

[0070] 1) Adopt static calibration method

[0071] ① Zero point calibration: do not add weights, wait until the weighing system of the lysimeter is in a stable state, and perform zero point calibration.

[0072] ②Repeated calibration: starting from the smallest weight, place the weight of each specification 5 times to measure 5 values, and finally take the average value.

[0073] ③Linear calibration: starting from the smallest weight, place weights of 200g, 300g, 500g, 700g, 900g, 1000g, 2000g, etc. for linear calibration, repeat the array, and take the average value to make a linear graph.

[0074] ④Maximum capacity calibration: place weights according to the required maximum capacity.

[0075] ⑤ Calibration result inspection: place weights in order, repeat multiple groups and record the value as figure 1 shown in the four tables.

[0076] 2) Fit a straight line accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com