Standard substance for calibration of plasma ablation tester and preparation method thereof

An ablation test and reference material technology, applied in the field of metrology, can solve the problem of not being able to meet the calibration needs of a plasma ablation test machine, and achieve the effects of convenient operation, good repeatability, and accurate and reliable setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] According to the uniformity and stability requirements of the standard substance, the present invention selects the commonly used carbon fiber reinforced phenolic resin as the raw material of the plasma line ablation rate standard substance of the thermal protection material.

[0022] (1) Sample preparation

[0023] Preparation of prepreg: Measure the solid content of S157 phenolic resin solution to be 53.0%. According to the ratio of carbon fiber to effective phenolic resin mass ratio of 1:4, weigh 50g of carbon fiber with a length of 8mm and 380g of phenolic resin solution, and mix them evenly , spread out on a polyester film, dry at room temperature for 4 days, and store in the refrigerator for later use.

[0024] Pre-baking pre-treatment: Weigh 5 parts (11±0.5) g of prepreg, place the prepreg in an oven at 100°C to soften for 30 minutes, and take it out when the prepreg becomes soft and slightly sticky.

[0025] Compression molding: Take out the pretreated prepreg ...

Embodiment 2

[0050] (1) Preparation of samples:

[0051] Preparation of prepreg: Measure the solid content of S157 phenolic resin solution to be 53.8%, weigh 50g of carbon fiber with a length of 6mm and 390g of phenolic resin solution according to the mass ratio of carbon fiber and effective phenolic resin of 1:4.2, mix them evenly, and spread them out Place it on a polyester film to dry for 4 days, and place it in the refrigerator for later use.

[0052] Pre-baking pre-treatment: Weigh 5 parts (11±0.5) g of prepreg, soften the prepreg in an oven at 105°C for 28 minutes, and take it out when the prepreg becomes soft and becomes slightly sticky.

[0053] Compression molding: Take out the pretreated prepreg and quickly put it into a mold preheated to 120°C, close the mold, and exhaust the air for 3 times. Start timing at ℃, and take out the sample after constant temperature for 14 minutes.

[0054] (2) Uniformity test

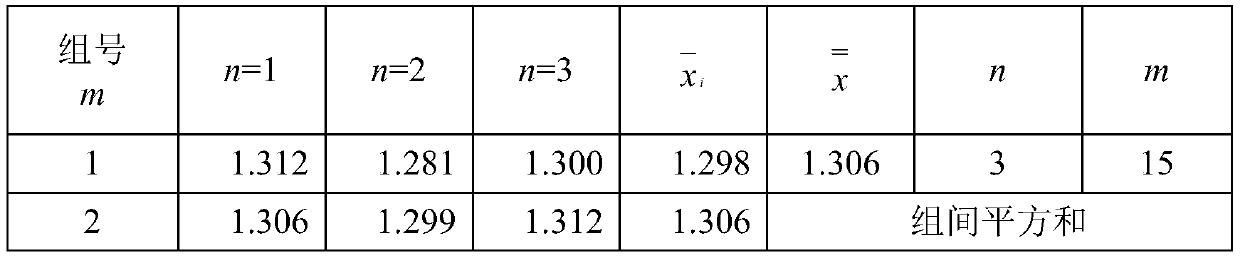

[0055] The uniformity test was carried out according to the method of...

Embodiment 3

[0065] (1) Preparation of samples:

[0066] Preparation of prepreg: Measure the solid content of S157 phenolic resin solution to be 54.2%, weigh 50g of carbon fiber with a length of 4mm and 352g of phenolic resin solution according to the mass ratio of carbon fiber and effective phenolic resin of 1:3.8, mix them evenly, and spread them out Place it on a polyester film to dry for 4 days, and place it in the refrigerator for later use.

[0067] Pre-baking pre-treatment: Weigh 5 parts (11±0.5) g of prepreg, soften the prepreg in an oven at 95°C for 32 minutes, and take it out when the prepreg becomes soft and becomes slightly sticky.

[0068] Compression molding: take out the pretreated prepreg and quickly put it into a mold preheated to 120°C, close the mold, and exhaust the air for 3 times. Start timing at ℃, and take out the sample after constant temperature for 16 minutes.

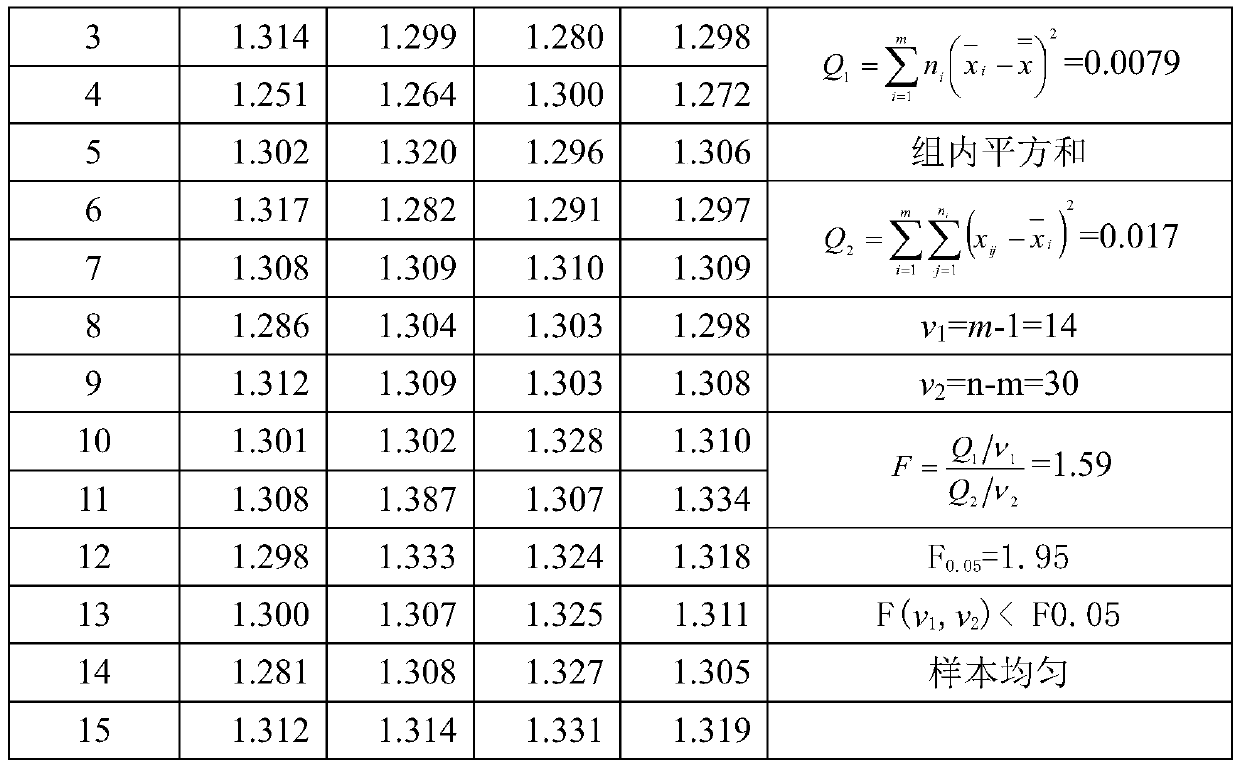

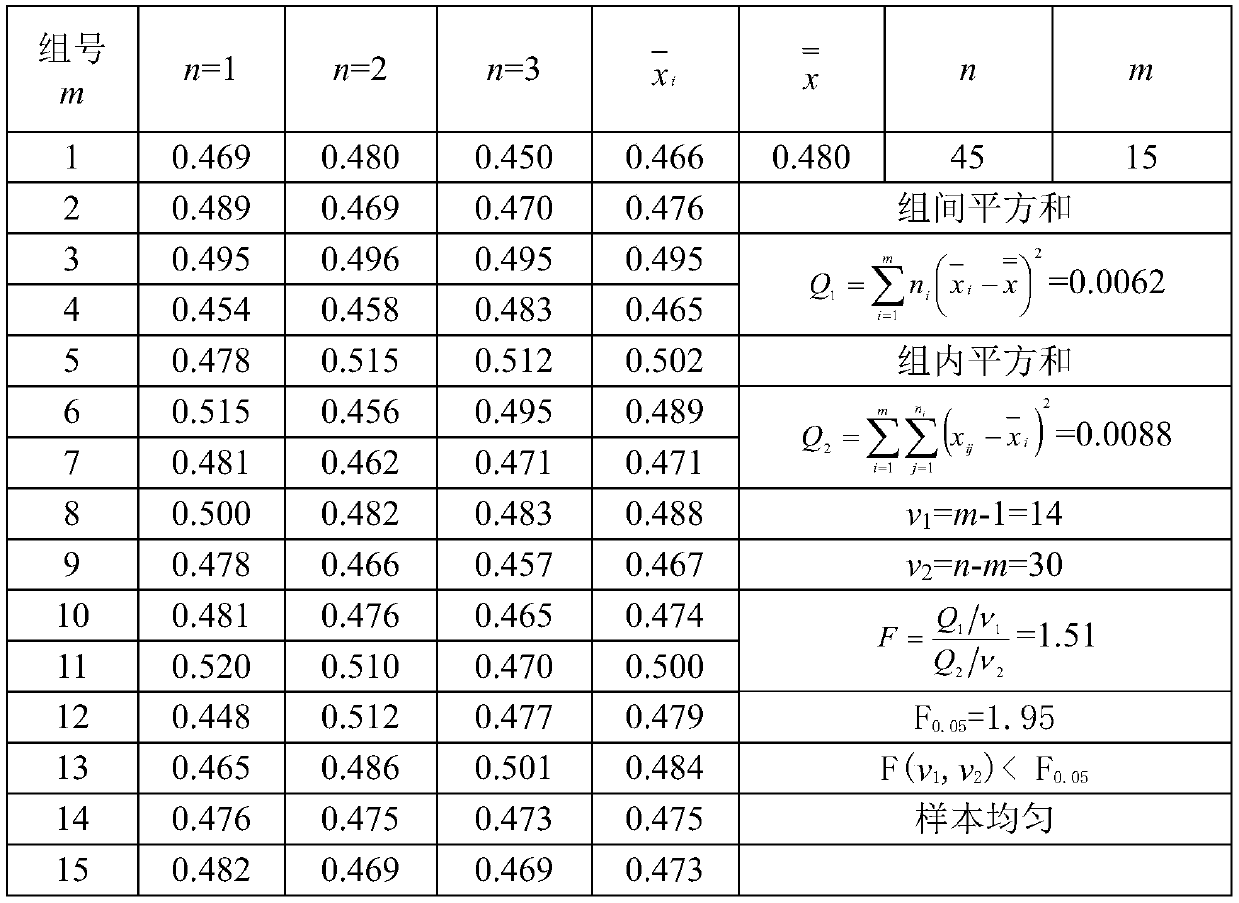

[0069] (2) Uniformity test

[0070] The uniformity test was carried out according to the method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com