Pulverized coil conveying belt safety inspection robot and use method thereof

A technology for inspection robots and conveyor belts, which is applied to instruments, motor vehicles, transportation, and packaging. It can solve problems such as difficult control, difficult ground movement, and poor reliability, so as to solve detection difficulties, reduce work intensity, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0049] In order to solve the above-mentioned technical problems, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

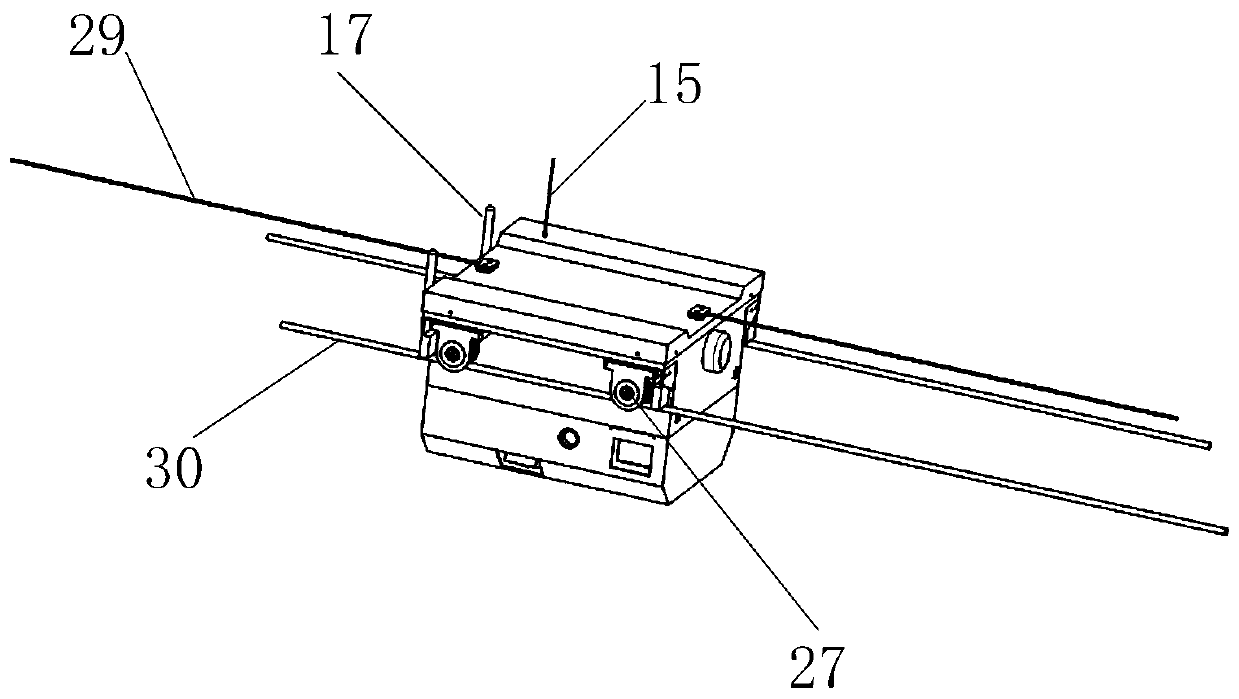

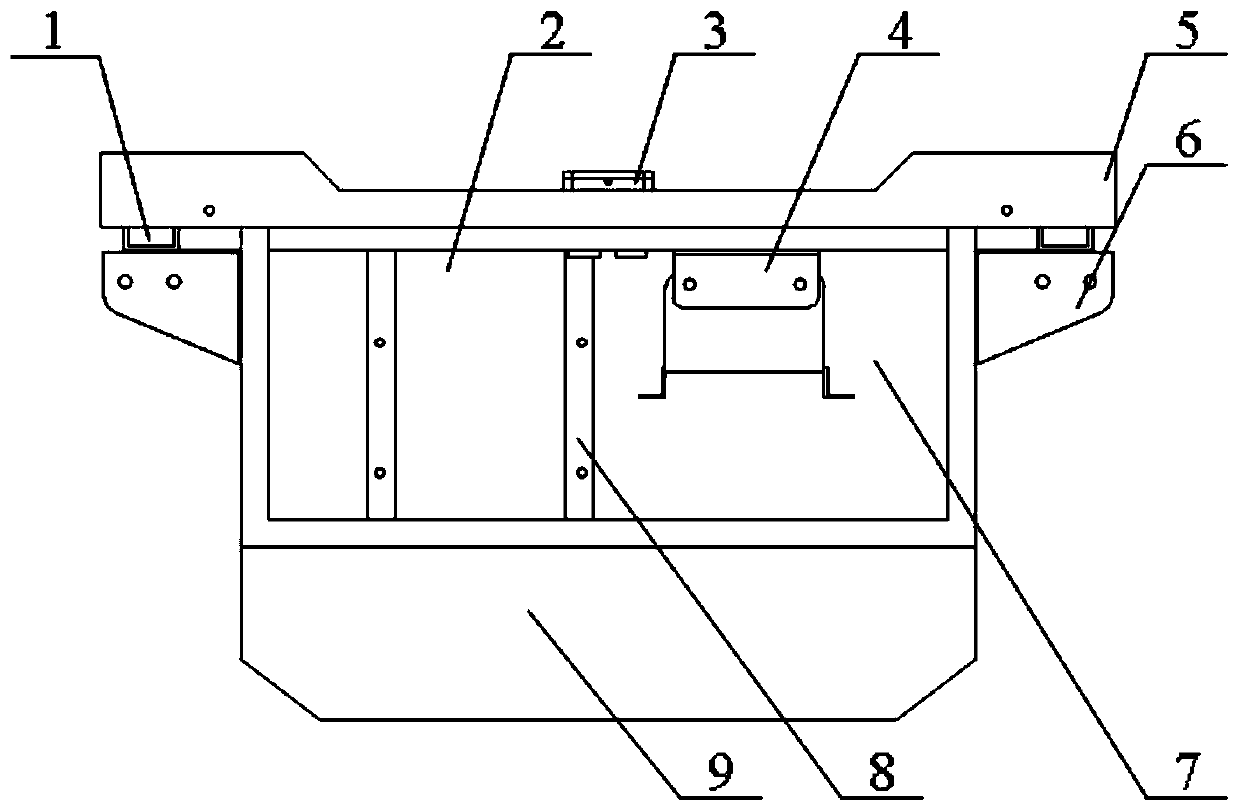

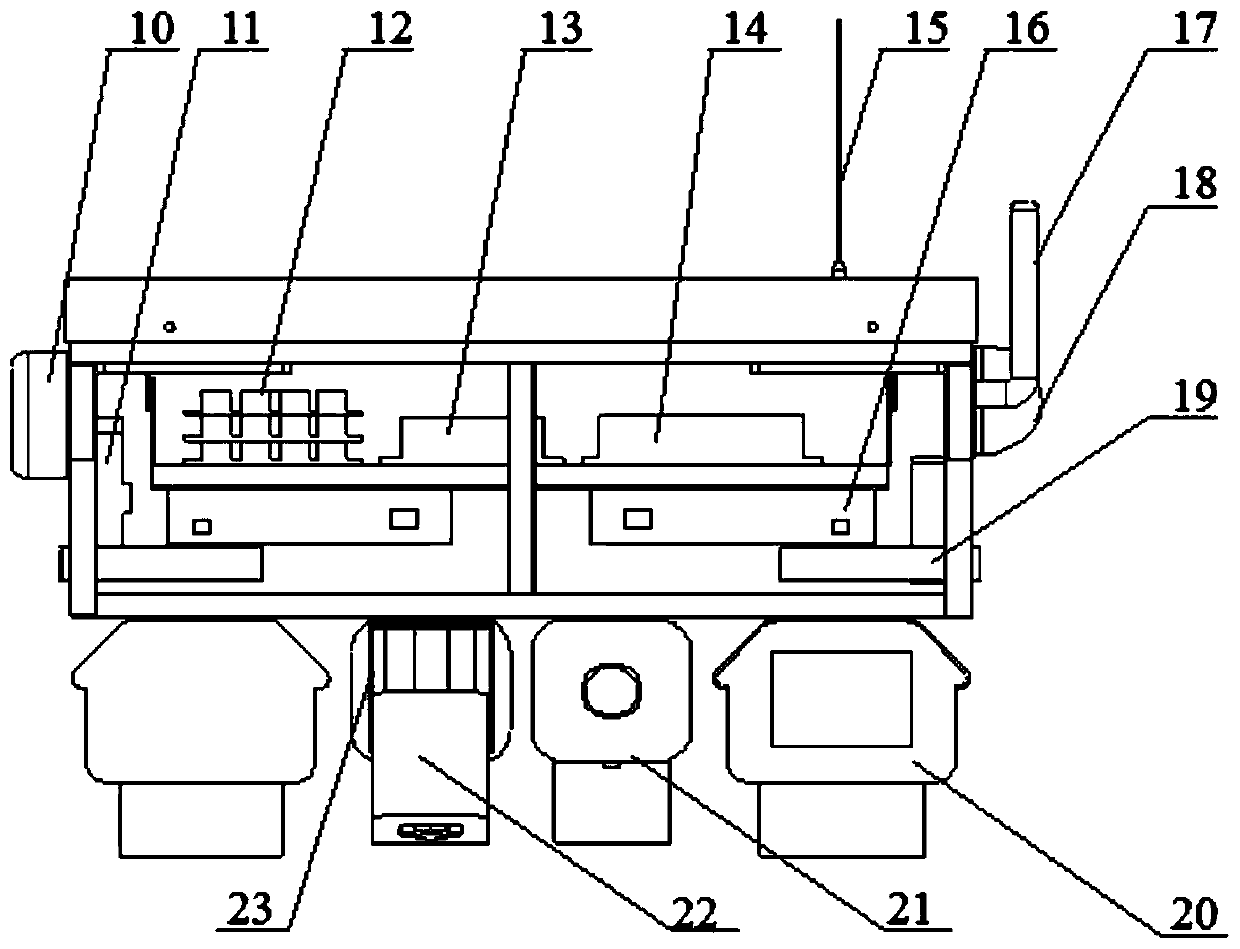

[0050] Such as Figure 1-Figure 4 As shown, the coal powder conveyor belt safety inspection robot is equipped with a robot body, a data acquisition and processing device, and a copper wheel power extraction device.

[0051] The robot body includes: an insulating plate 1 , a protective plate 2 , a rope connecting device 3 , a connecting plate 4 , an upper cover plate 5 , a first baffle plate 6 , a first bracket 7 , a frame 8 , and a lower casing 9 .

[0052] The robot body is provided with a frame 8, and the frame 8 is welded by square pipes and angle steel; an upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com