A front-encoder disc type ultra-thin permanent magnet synchronous traction machine

A technology of synchronous traction machine and encoder, which is applied in the direction of magnetic circuit, electromechanical device, control mechanical energy, etc., can solve the problem that the pre-encoder cannot be replaced normally, affects the operation accuracy and life of the pre-encoder, and cannot provide To solve problems such as encoder pre-solution, to reduce the risk of encoder damage, improve the effect of encoder damage or waveform distortion, and improve heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

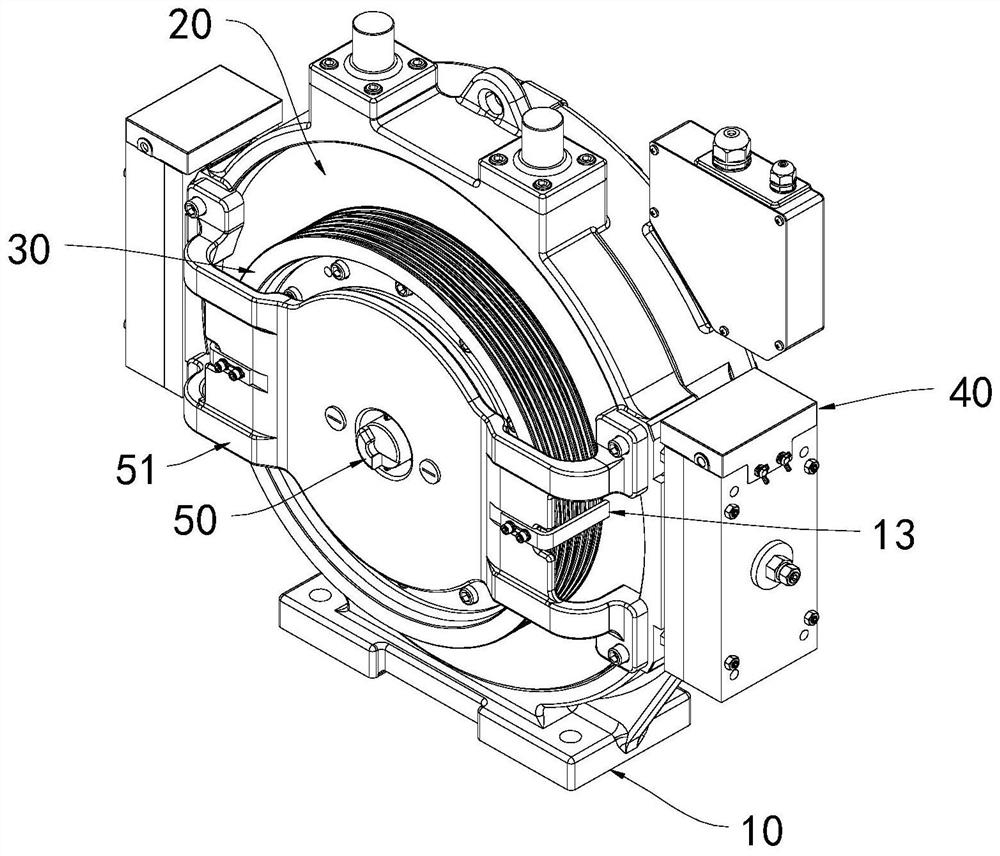

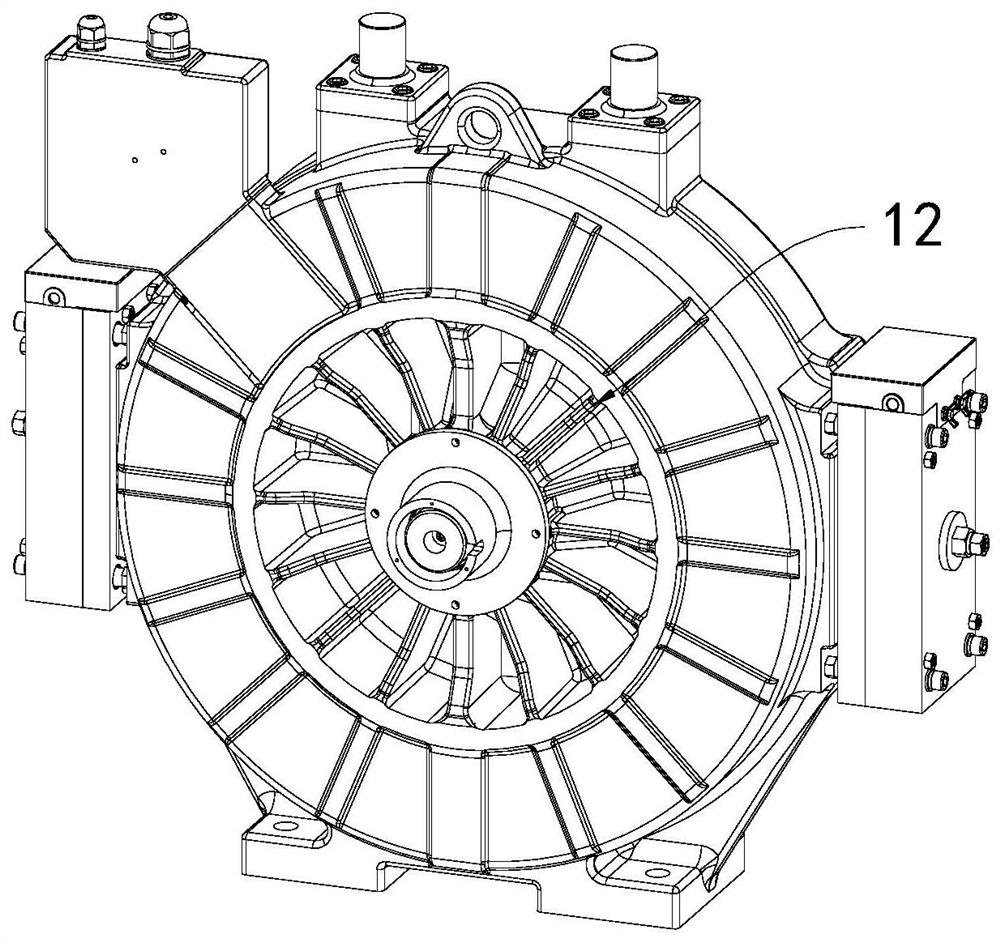

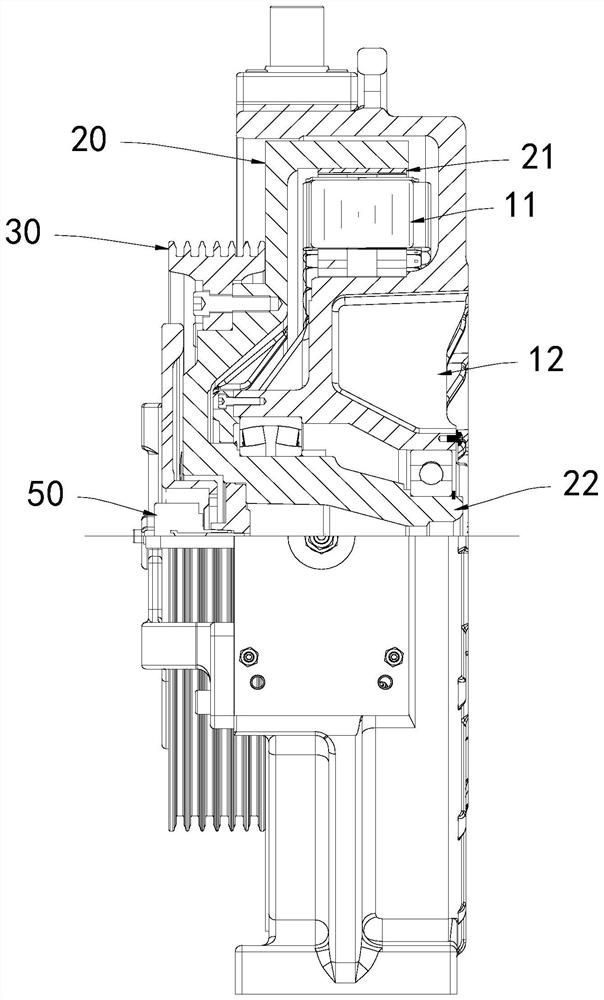

[0041] Embodiment: An ultra-thin permanent magnet synchronous traction machine includes a frame 10 on which a stator 11 is provided; and a rotor 20 on which is provided a magnet covering the coil of the stator 11 and forming a radial magnetic field with it 21. The tooth shape of the stator 11 is T-shaped; the rotor 20 is a disc-shaped shell with one end uplifted. The rotor 20 is provided with a shaft 22 on the inner side of the uplift that is rotatably matched with the base 10. The shaft 22 is provided with a front bearing and a rear bearing. Bearing, the rotor 20 is provided with a traction sheave 30 on the outside of the bulge; it also includes a brake 40, an encoder 50 and a junction box that cooperate with the rotor 20.

[0042] The rotor hub and the shaft 22 are integrated or separated, and the permanent magnets are fixed on the inner surface of the hub to form a radial magnetic field structure with the stator 11. The magnetic tension is symmetrically offset, and there is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com