Separation and dust collection assembly and dust collector with same

A technology of separating sets and components, applied in vacuum cleaners, suction filters, household appliances, etc., can solve problems such as easy accumulation of dust and turbulent air flow at the dust-gas separator, so as to prevent dust, increase volume, reduce disordered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

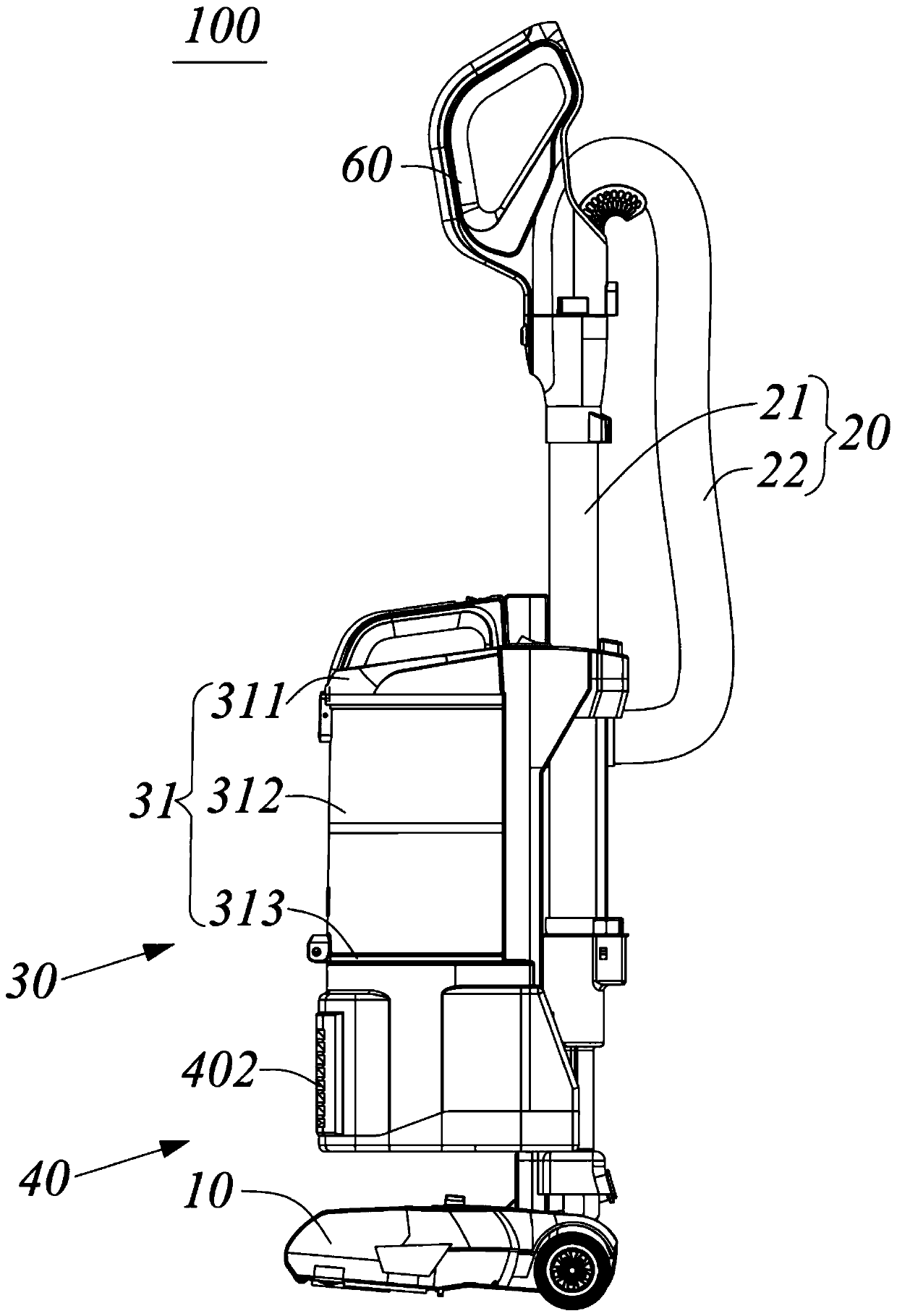

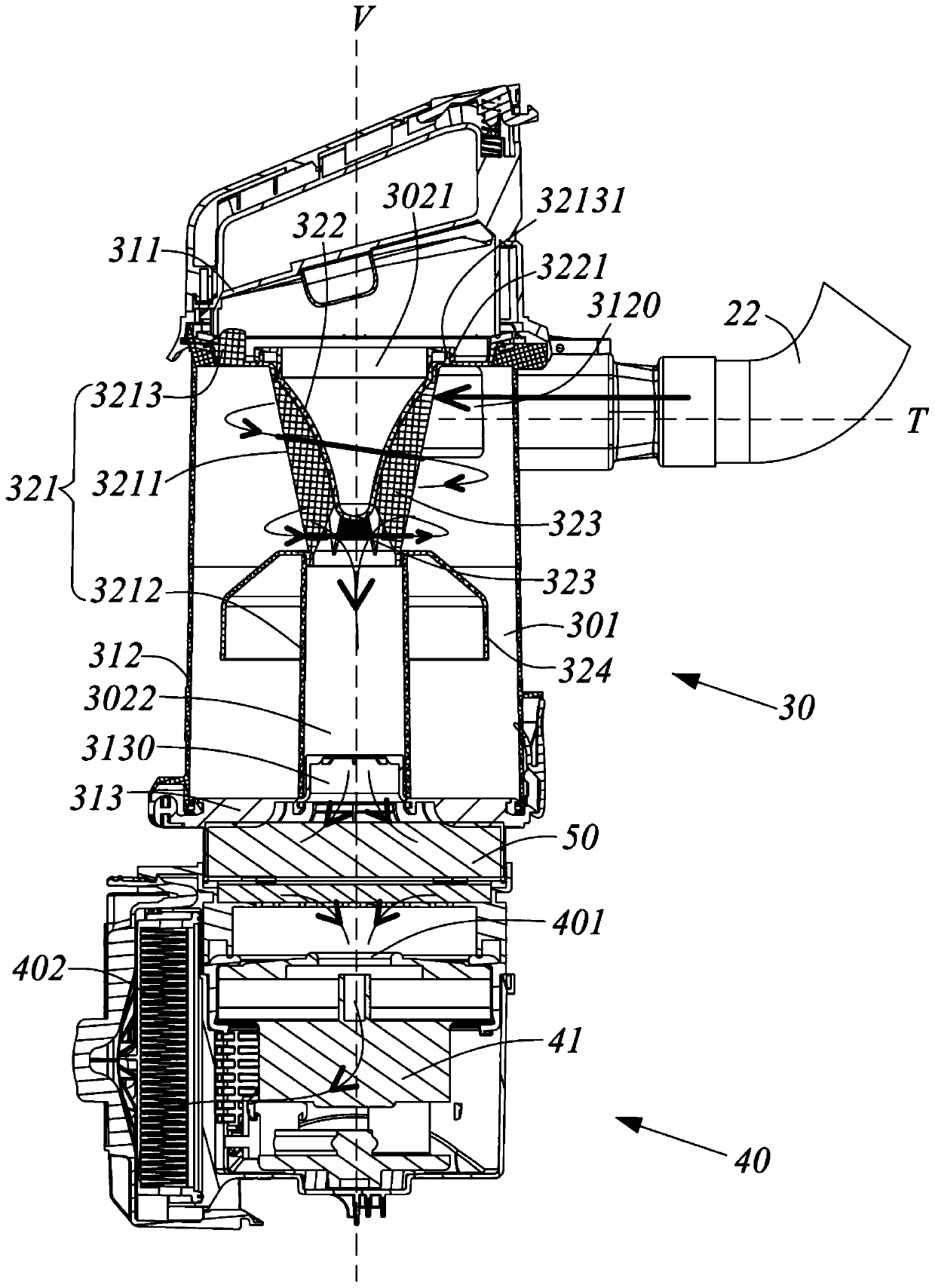

[0054] Such as Figure 1 to Figure 5 A preferred embodiment of the vacuum cleaner of the present invention is shown. The vacuum cleaner 100 is illustrated as an upright vacuum cleaner in this embodiment, but it is certainly not limited thereto. The vacuum cleaner of the present invention can also be implemented as a horizontal vacuum cleaner, a portable vacuum cleaner, a robot vacuum cleaner / sweeping floor machine and so on.

[0055] In this example, see figure 1 , The vacuum cleaner 100 includes a working head assembly 10 , a pipe assembly 20 , a separated dust collection assembly 30 , a suction assembly 40 and a handle assembly 60 .

[0056] The working head assembly 10 includes any one of ground brushes, round brushes, sweeping brushes, flat suction or other types of brushes or suction heads. The working head assembly 10 is formed with a suction port of the vacuum cleaner 100 .

[0057] The tube assembly 20 includes a rigid straight tube 21 extending longitudinally and a ...

Embodiment 2

[0094] ginseng Figure 6 to Figure 8 , shows another preferred embodiment of the present invention, and components with the same or similar features as in Embodiment 1 are marked with the same symbols as in Embodiment 1 combined with the letter "a" in this embodiment.

[0095] The difference between this embodiment and Embodiment 1 mainly lies in: the connection mode between the skirt and the main mechanism. The following will only describe this difference in detail, and other parts that are the same as those in Embodiment 1 will not be repeated here.

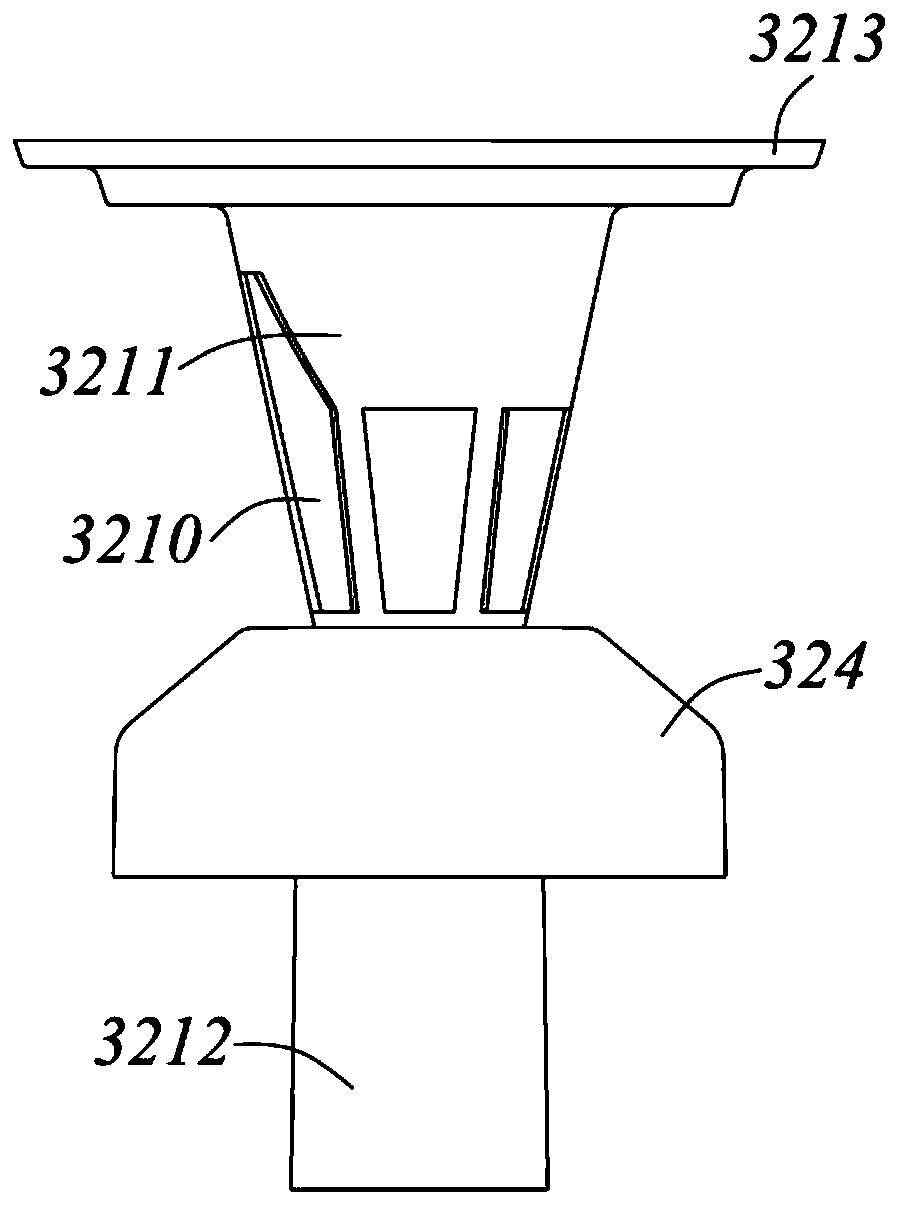

[0096] ginseng Figure 6 to Figure 8 Different from the integral arrangement of the skirt 324 and the separation cylinder 3211 in Embodiment 1, the skirt 324a and the separation cylinder 3211a are separately provided in this embodiment, and the skirt 324a is assembled and sleeved outside the main mechanism 321a.

[0097]Specifically, the top middle of the skirt 324a has a channel 3241a; the main body mechanism 321a is provide...

Embodiment 3

[0101] ginseng Figure 9 , shows another preferred embodiment of the present invention, and components with the same or similar features as those in Embodiment 1 are marked with the same symbols as in Embodiment 1 combined with the letter "b" in this embodiment.

[0102] The difference between this embodiment and Embodiment 1 mainly lies in the extension direction of the air inlet of the dust cup. The following will only describe this difference in detail, and other parts that are the same as those in Embodiment 1 will not be repeated here.

[0103] ginseng Figure 9 Unlike the extending direction T of the air inlet 3120 in Embodiment 1 which is the tangent to the side wall 312 of the dust cup 31, in this embodiment, the extending direction Tb of the air inlet 3120b is not the tangent to the side wall 312b of the dust cup 31b. Specifically, in this embodiment, the side wall 312b is in the shape of a cylinder arranged around the central axis Vb, and its air inlet 3120b extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com