Cleaning and dust-removal equipment for high-pressure micro-fog multi-layer filtration of silk fabrics

A technology of multi-layer filtration and dust removal equipment, applied in the direction of filtration and separation, the use of liquid separators, fixed filter element filters, etc., can solve the problems of miscellaneous lines, mixed fluff, prone to liquefaction, loud noise, etc., to achieve clean and comfortable The effect of purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

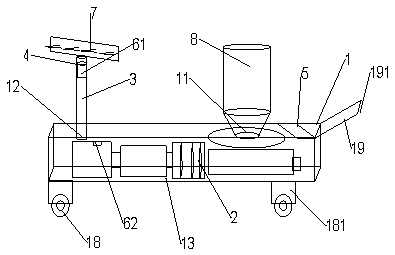

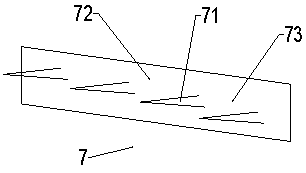

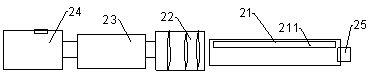

[0015] Such as Figure 1 to Figure 3 As shown, the present invention is a high-pressure micro-mist multi-layer filter cleaning and dust removal equipment used for silk fabrics, including a device body frame 1, a high-pressure micro-mist assembly 2, a high-pressure spray rod 3, a rotating mechanism 4, a control panel 5, and a micro-sensing assembly 6. Spray nozzle plate assembly 7 and water storage tank 8. The high-pressure micro-mist assembly 2 includes a water storage filter box 21, a three-layer filter mechanism 22, a pneumatic booster pump 23 and a high-pressure water storage tank 24. The micro-sensing assembly 6 is composed of a rotary controller 61 and a pressure sensor 62. The surface of the equipment body frame 1 is provided with a water inlet 11, a water outlet 12 and a maintenance door 13. The inner surface of the water inlet 11 is buckled and connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com