ABS board machining method and equipment

A processing method and equipment technology, applied in the field of ABS board processing methods and equipment, to achieve the effects of improving aesthetic performance, ensuring sealing performance, and good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

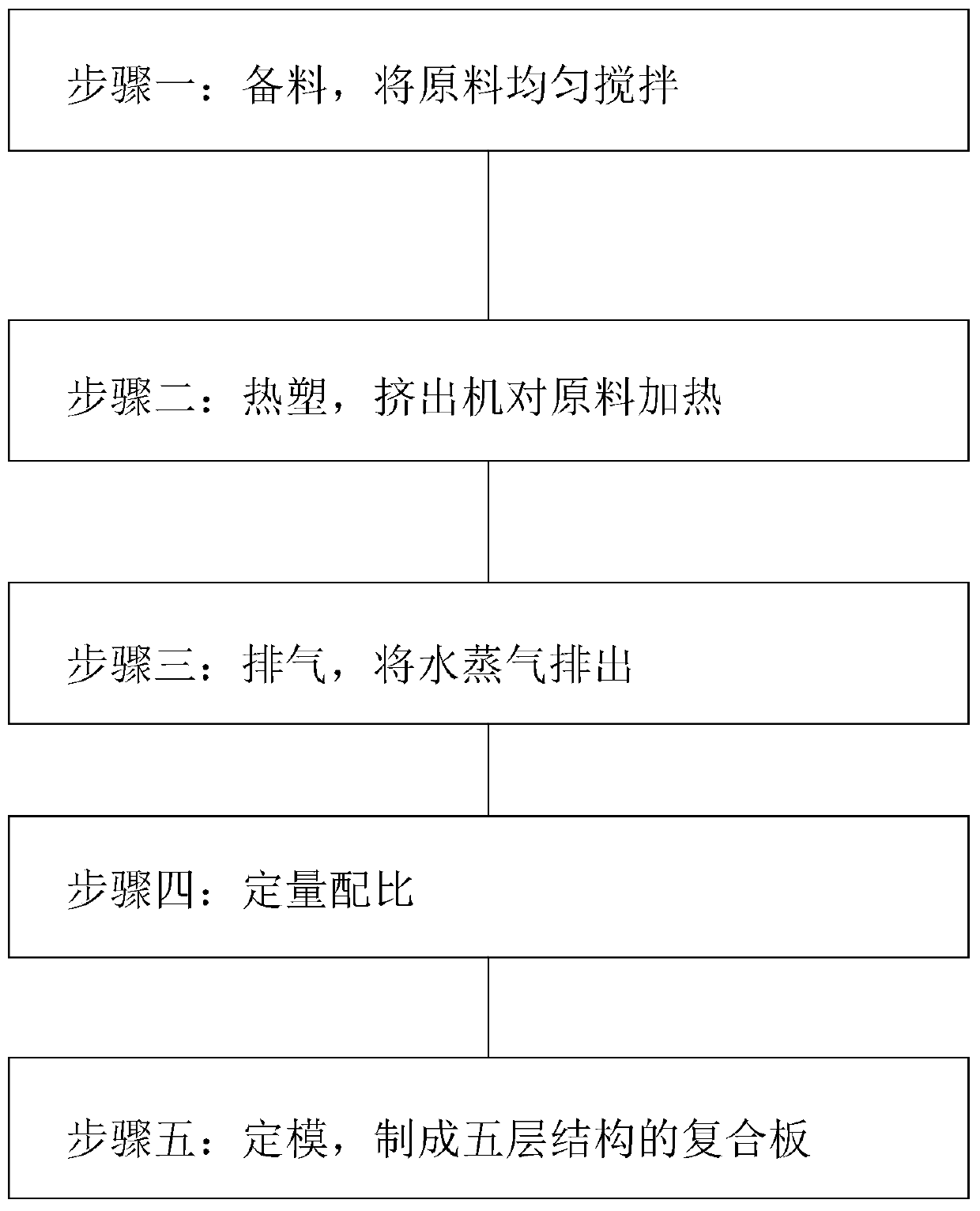

[0044] refer to image 3 , is a kind of ABS plate processing method disclosed by the present invention, comprises the following steps:

[0045] Step 1, prepare materials, inject ABS raw materials, ASA raw materials, PMMA raw materials and sound insulation raw materials into four mixers, start the mixers, and mix the raw materials evenly;

[0046]Step 2: thermoplastic, the extruder heats the raw material;

[0047] Step 3, exhaust, the water vapor in the raw material after hot melting is discharged from the vent hole of the barrel;

[0048] Step 4, quantification, quantitative extrusion of ABS raw materials, ASA raw materials, PMMA raw materials and sound insulation raw materials;

[0049] Step 5: Fixing the mould, injecting raw materials into five groups of corresponding mold cavities in the mould, and making a five-layer composite board.

[0050] The first choice is to put the ABS raw material, ASA raw material, PMMA raw material and sound insulation raw material into four ...

Embodiment 2

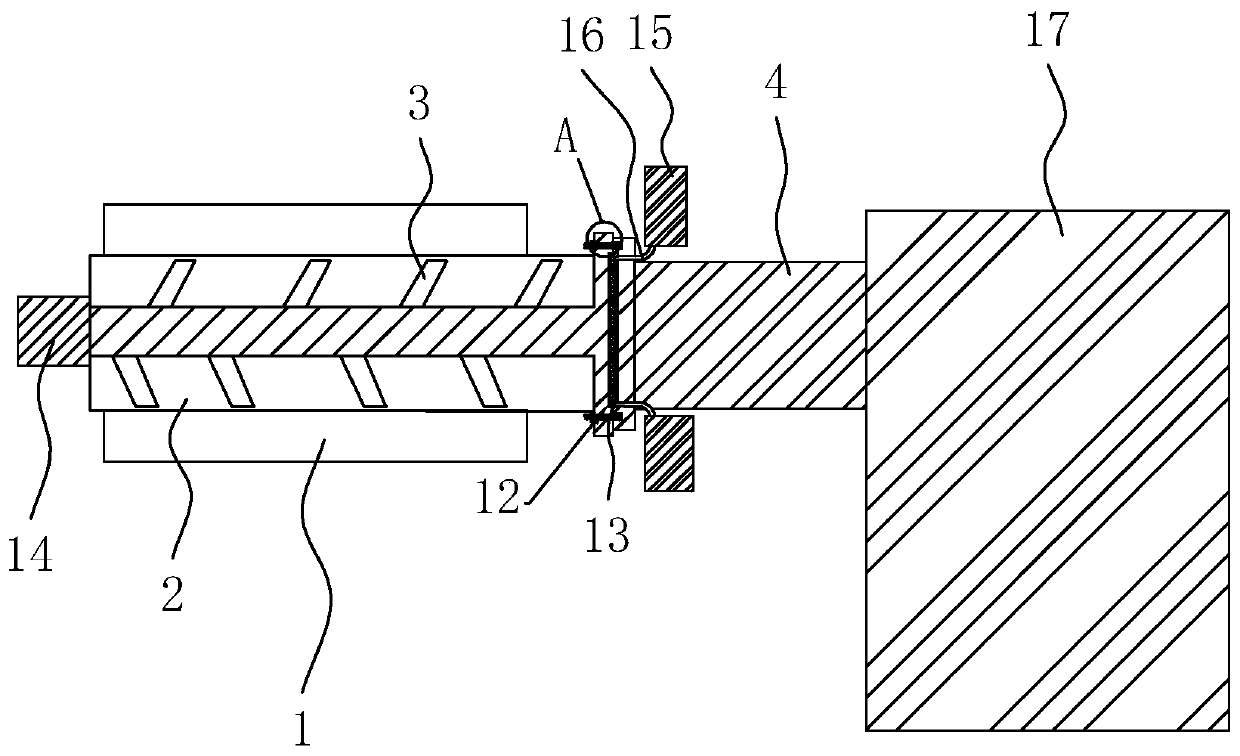

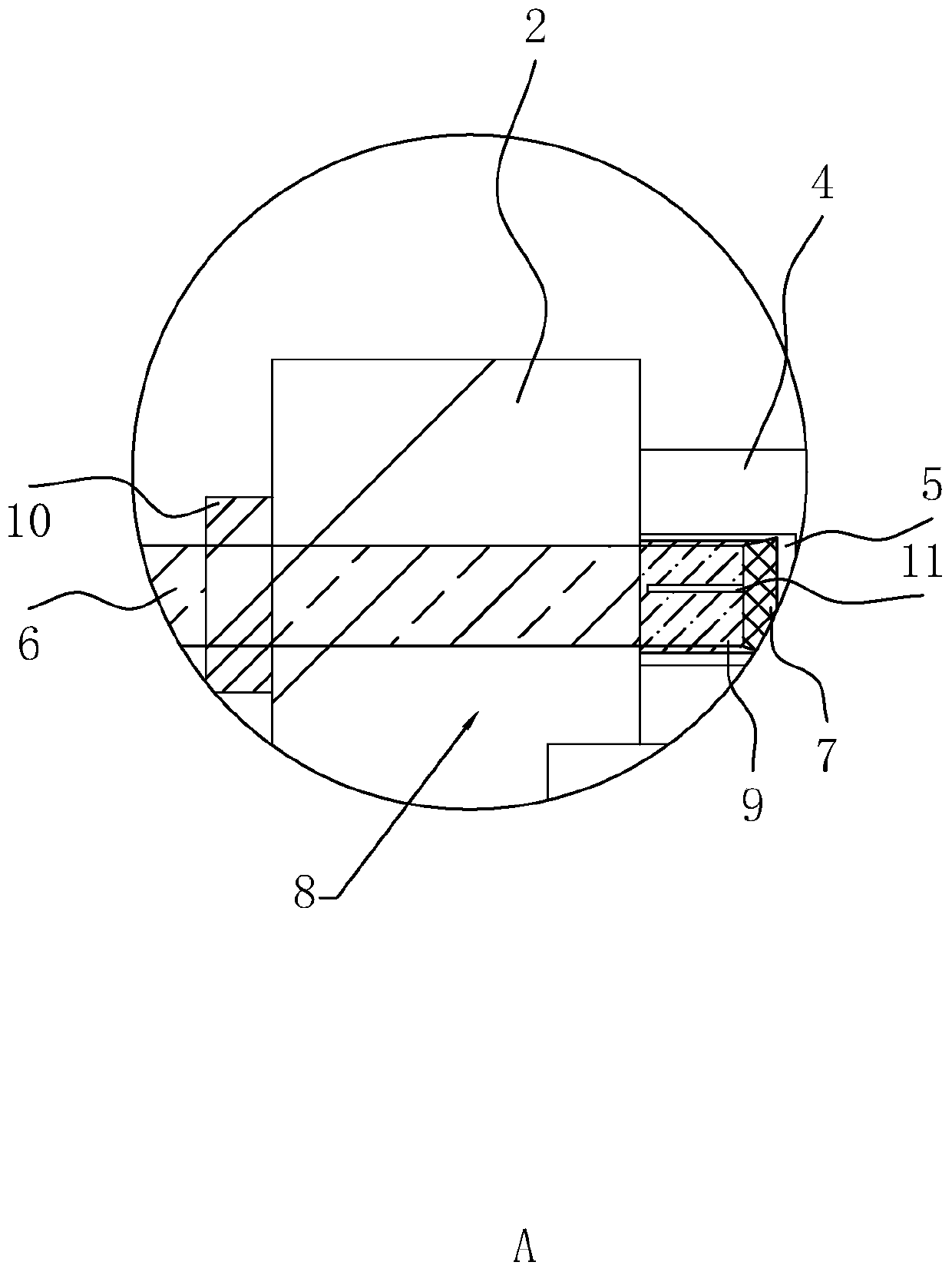

[0057] refer to figure 2 , is a kind of processing ABS plate equipment disclosed by the present invention, comprises frame 1, mold 17 and four groups of extruders, and described extruder has the equipment that is used for injection molding in the prior art, and extruder comprises barrel 2 As well as the screw blade 3, the four groups of barrels 2 are respectively injected with ABS raw materials, ASA raw materials, PMMA raw materials and a mixture of polyamide fiber and glass fiber, and the thermoplastic temperature of PMMA raw material is 190-240 ° C, and the thermoplastic temperature of ASA raw material is 180-220°C, the thermoplastic temperature of ABS raw material is 185-230°C, and the thermoplastic temperature of polyamide fiber and glass fiber is 215-220°C; the temperatures in the four sets of barrels 2 correspond to the corresponding temperatures of different raw materials.

[0058] refer to figure 2 , in order to facilitate the control of the injection amount of raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com