Energy-saving control method for electric automobile driven by four-wheel hub motor

A hub motor and electric vehicle technology, applied in the field of control, can solve the problems of small scope of application, not making full use of the advantages and potential of four-wheel hub motors to drive electric vehicles, and not combining energy-saving control and stability control with vehicle active safety control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

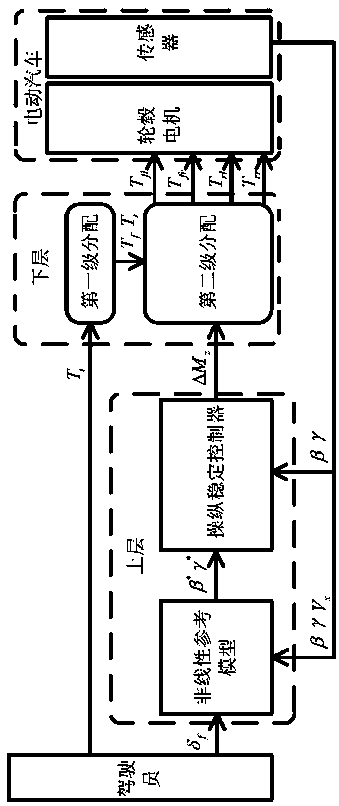

[0110] The invention overcomes the shortcomings of the existing methods, and provides an energy-saving control method for the electric vehicle based on a layered control structure for an electric vehicle whose four wheels are hub motors. The hierarchical control method is divided into upper and lower layers,

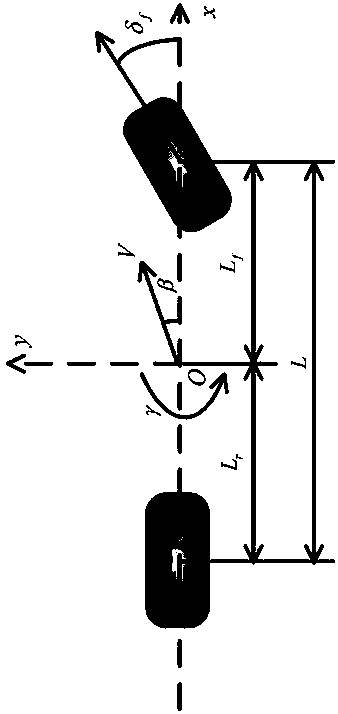

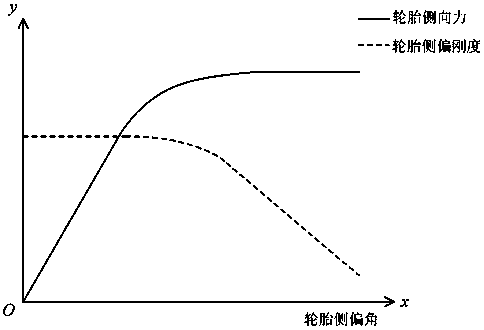

[0111] The upper layer calculates the ideal vehicle state according to the driver's needs, and outputs the additional yaw moment to make the actual state of the vehicle track the ideal state, more precisely, to make the actual yaw rate of the vehicle track the ideal value, thereby achieving energy saving and stability the goal of. According to the additional yaw torque output by the upper layer, the lower layer optimally allocates the driver’s total torque demand to the four in-wheel motors through a two-stage distribution. Based on these objectives and constraints, the total torque output by the driver is optimally distributed to the front and rear axles of the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com