Antibacterial elevator car and manufacturing method thereof

A technology for elevator car and elevator control, which is applied in elevators, disinfection, construction and other directions in buildings, can solve the problems of insufficient sterilization, high cost, low adhesion, etc., so as to reduce elevator downtime and prevent oxidation corrosion. , the effect of improving light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

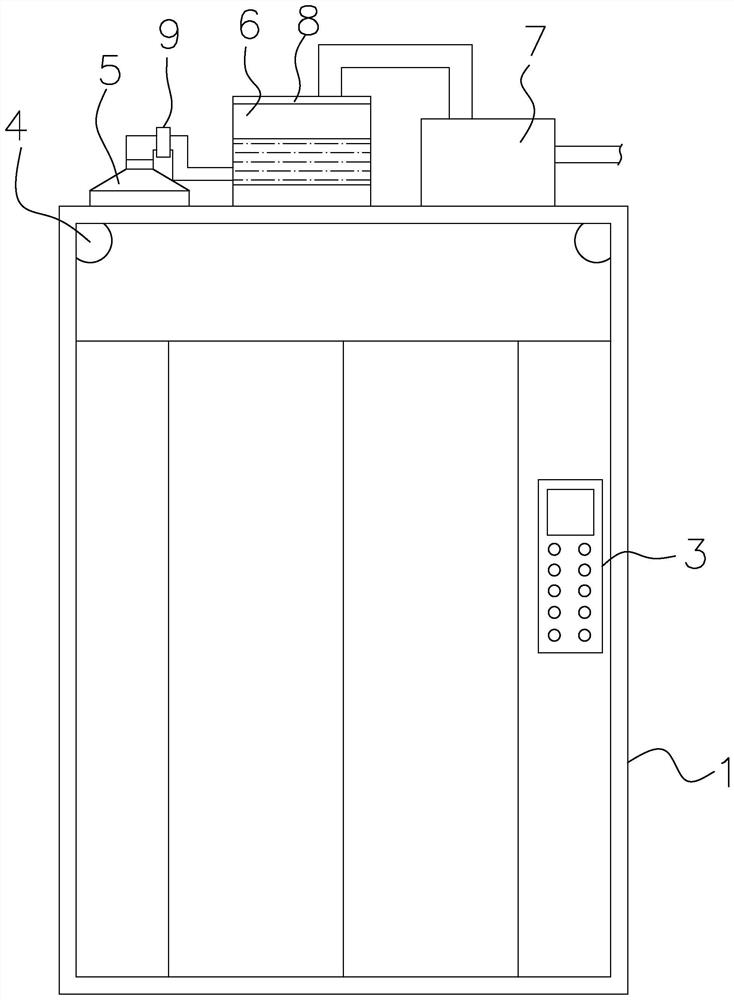

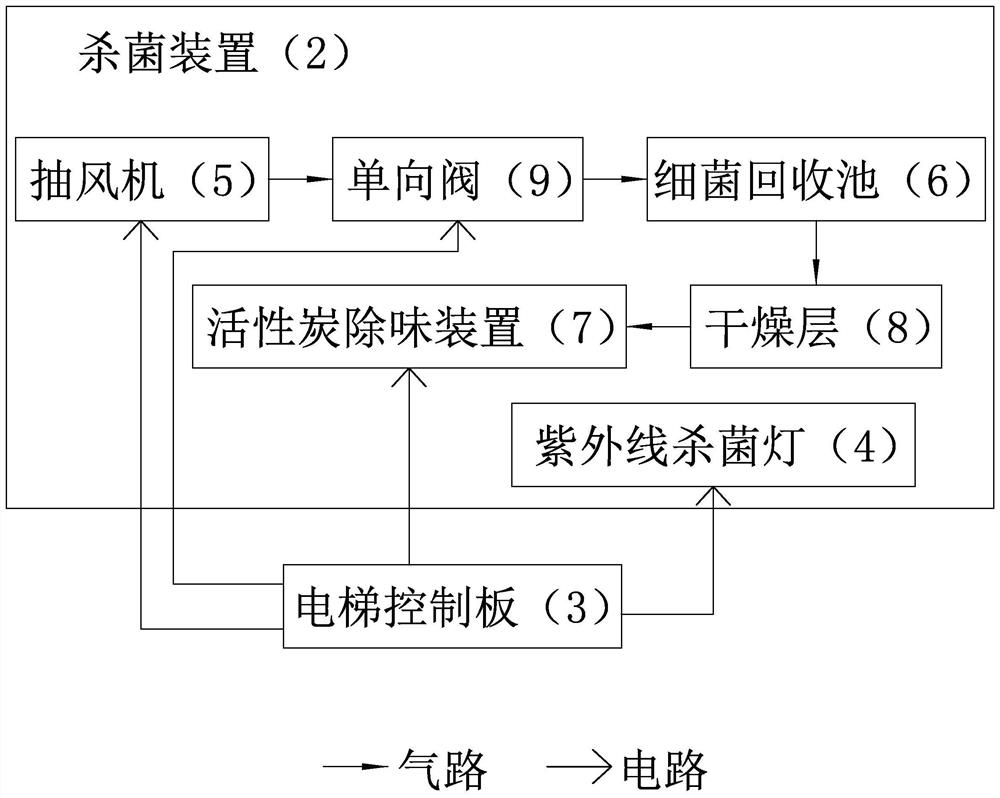

[0026] Such as figure 1 with figure 2 As shown, this embodiment discloses an antibacterial elevator car, including a car body (1), a sterilizing device (2) is installed in the car body (1), and the surface of the car body (1) Covered with an antibacterial layer, the car body (1) is separated from the antibacterial coating by an anti-oxidation layer, and an elevator control panel (3) is installed inside the car body (1), and the elevator control panel (3) It is electrically connected with the sterilizing device (2), and the car body (1) is composed of spliced car panels.

[0027] A method for manufacturing an antibacterial elevator car, the preparation steps of forming an antibacterial layer on the surface of the car body (1) are as follows:

[0028] Step 1. Wash the car board to be treated with detergent and water for 3 to 5 times respectively, and take out the cleaned car board for later use;

[0029] Step 2, carrying out oxidation treatment to the car plate cleaned in ...

Embodiment 2

[0045] The implementation content of this embodiment is roughly the same as the implementation content of Embodiment 1, the difference is: in the antibacterial treatment process of the car plate, the following raw materials Na 2 O: 8 to 12 parts, C 36 h 70 CaO 4 : 10-15 parts, Ag 2 O: 15-20 parts, NaCl: 15-20 parts, AgNO 3 : 10-15 parts are put into an organic solvent and mixed by high-speed centrifugation to prepare a spray with a concentration of 15g / L. The spray is sprayed on the surface of the car plate by atomization spraying. The spraying process is as follows:

[0046] (1) Clean the car plate to be sprayed first, and use alcohol and other organic solvents to remove the oil stains on the surface of the car plate;

[0047] (2) Start spraying, use a pneumatic spray gun to spray, in which the nozzle diameter of the spray gun is 1.0mm, and spray at a relatively long distance from the sprayed part during spraying, and ensure uniform atomization without particle droplets; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com