Preparation method of high-performance permeable concrete prepared by building rubbish

A technology of permeable concrete and construction waste, which is applied in the direction of cohesive pavement paved on site, construction, and climate sustainability, can solve the problems of unutilized construction waste, consumption of permeable concrete, and large non-renewable energy, and achieve effective Conducive to sustainable development and the effect of improving water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the high-performance permeable concrete is as follows:

[0029] Step 1: Classify construction waste, select concrete waste, mud waste and asphalt waste;

[0030] Step 2: Separately select concrete waste, mud waste and asphalt waste, remove dirt and dust on the surface of concrete waste, remove sundries in mud waste, and remove bricks and stones in asphalt waste;

[0031] Step 3: Place concrete waste in a crusher for crushing, and asphalt waste for heating;

[0032] Step 4: Sieve the pulverized concrete blocks, and filter the remaining concrete blocks for secondary crushing and then sieve;

[0033] Step 5: add mud, asphalt, cement, water and rubber powder to the sieved concrete;

[0034] Step 6: Put the mixed mixture into the cement mixer for stirring;

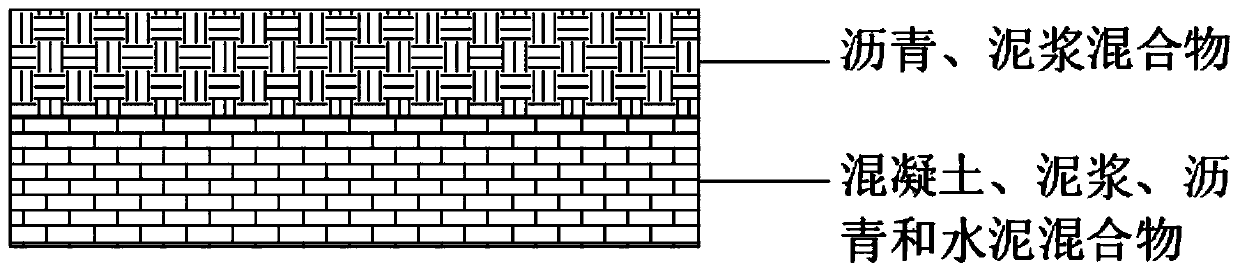

[0035] Step 7: Lay the stirred mixture on the ground, wait for it to be semi-dry, and then lay a layer of asphalt and mud mixture on the surface, and wait for it to dry completely.

[0036] ...

Embodiment 11

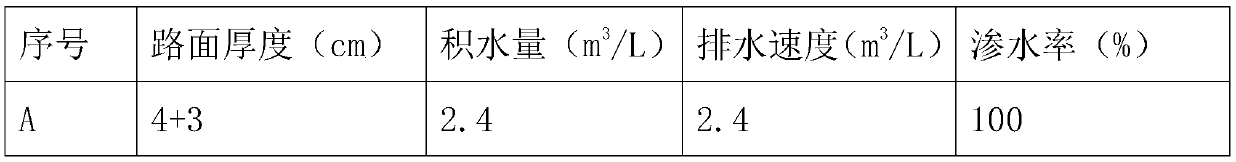

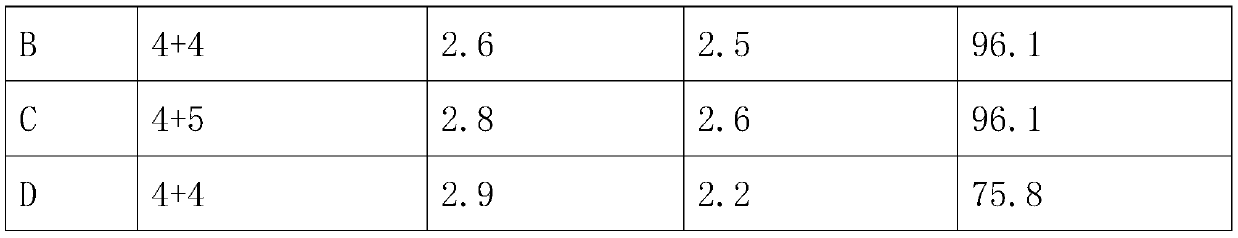

[0045] The steps of this embodiment are the same as those of Embodiment 1, except that in step 7, the thickness of the mixture paved is 5 cm, and the thickness of the asphalt paved is 3 cm.

Embodiment 12

[0047] The steps of this embodiment are the same as those of Embodiment 1, except that in step 7, the thickness of the mixture paved is 6 cm, and the thickness of the asphalt paved is 3 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com