Preparation method of full bio-based vitrimer

An all-biological and derivative technology, applied in the field of preparation of all-bio-based vitrimer, can solve the problems of difficult recycling and reprocessing, mechanical properties, poor solvent resistance, unstable structure, etc., and achieve easy implementation, good biocompatibility, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

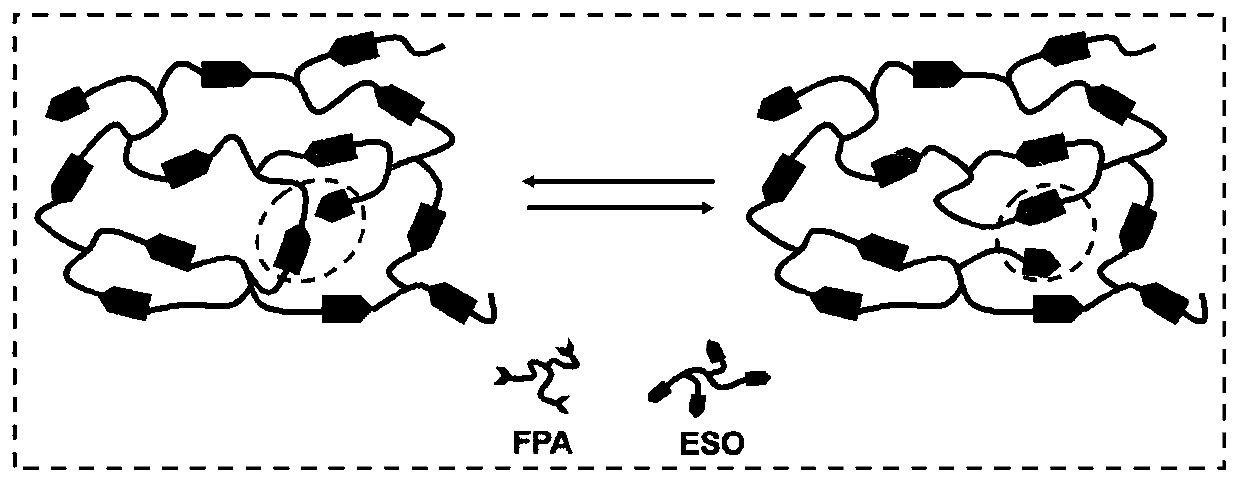

Method used

Image

Examples

Embodiment 1

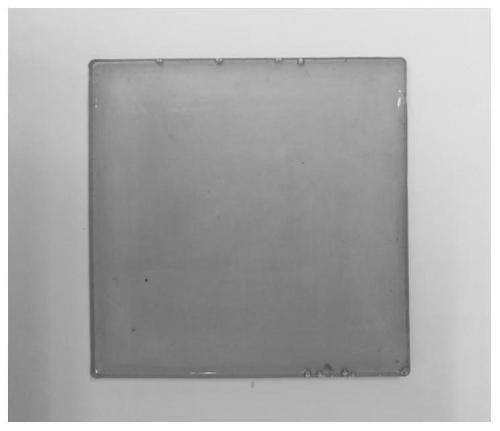

[0035] Dissolve 3 g of rosin resin acid derivative fumaric acid (FPA) in 12 g of dehydrated ethanol, then add 0.1 g of transesterification catalyst zinc acetylacetonate to the above-mentioned clear solution, and mix well at 50° C. to obtain a uniform Colorless solution, then add 5g epoxidized soybean oil (Shanghai Wenhua Chemical Pigment Co., Ltd., epoxy value ≥ 6) and mix; Add the above solution into an eggplant type bottle and remove the solvent ethanol by rotary evaporation; The final viscous liquid is poured into a tetrafluoroethylene mold, and the mold is placed in a vacuum drying oven. After decompression and vacuuming, nitrogen gas is introduced, cured at 120°C for 2 hours, and the temperature is raised to 140°C at 5°C / min. Then post-cure at 140°C for 5 hours to obtain a transparent yellow film material.

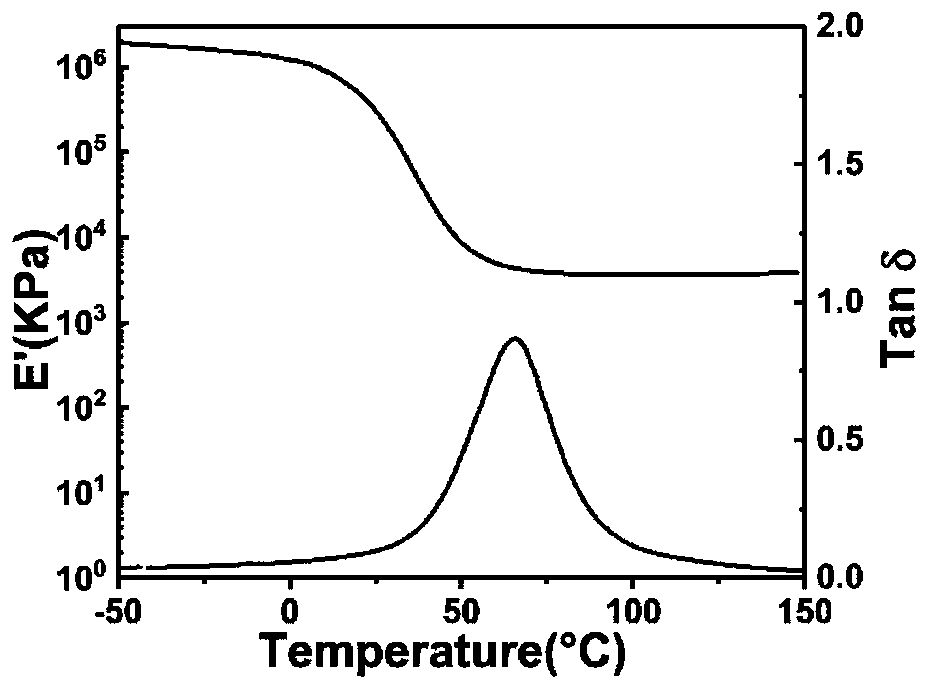

[0036] The glass transition temperature of the material is 65°C and the tensile strength is 16MPa. Scratch the obtained vitrimer material with a blade (the width of ...

Embodiment 2

[0038] 2.4g of rosin resin acid derivative fumaric acid (FPA) was dissolved in 10g of absolute ethanol, then 0.15g of transesterification catalyst zinc acetylacetonate was added to the above transparent clear solution, and mixed at 50°C to obtain Uniform colorless solution, then add 5g epoxidized soybean oil (Shanghai Aladdin Reagent Co., Ltd.) and mix well; add the above solution into an eggplant-shaped bottle and remove the solvent ethanol by rotary evaporation; the viscous liquid after rotary evaporation Pour it into a tetrafluoroethylene mold, and place the mold in a vacuum drying oven. After decompression and vacuuming, nitrogen gas is introduced, and it is cured at 110°C for 2 hours. After curing for 4 hours, a transparent yellow film material is obtained.

[0039]The glass transition temperature of the material is 56 °C, and the tensile strength is 14.6 MPa. Scratch the obtained vitrimer material with a blade (the width of the scratch is about 120 μm) and put it in an ...

Embodiment 3

[0041] 2.4g of rosin resin acid derivative maleopimaric acid (MPA) was dissolved in 9g of absolute ethanol, then 0.15g of transesterification catalyst zinc acetylacetonate was added to the above transparent clear solution, and mixed at 50°C to obtain Uniform colorless solution, then add 5g epoxidized soybean oil and mix evenly; add the above solution into an eggplant-shaped bottle and remove the solvent ethanol by rotary evaporation; pour the viscous liquid after rotary evaporation into a tetrafluoroethylene mold, And place the mold in a vacuum drying oven. After decompression and vacuuming, nitrogen gas is introduced, cured at 120°C for 2 hours, heated to 140°C at 5°C / min, and post-cured at 140°C for 6 hours to obtain a transparent Yellow film material.

[0042] The glass transition temperature of the material is 60° C., and the tensile strength is 13.2 MPa. Scratch the obtained vitrimer material with a blade (scratch width is about 135 μm) and put it in an oven at 170 ° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap