Odor-proof sole and processing method thereof

A processing method and technology for shoe soles, which can be applied to shoe soles, footwear, footwear, etc., can solve problems such as easy odor, and achieve the effect of scientific processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A kind of deodorant sole, is characterized in that,

[0024] The raw materials of the sole include: 20kg of EVA7350, 35kg of EVA7470, 4kg of polyethylene, 5kg of EPDM rubber, 6kg of talcum powder, 1.8 kg of antibacterial agent, 1.2 kg of antioxidant, 2 kg of deodorant, 1 kg of zinc oxide, 550 g of zinc stearate, 320 g of stearic acid, 420 g of crosslinking agent, 1.8 kg of blowing agent.

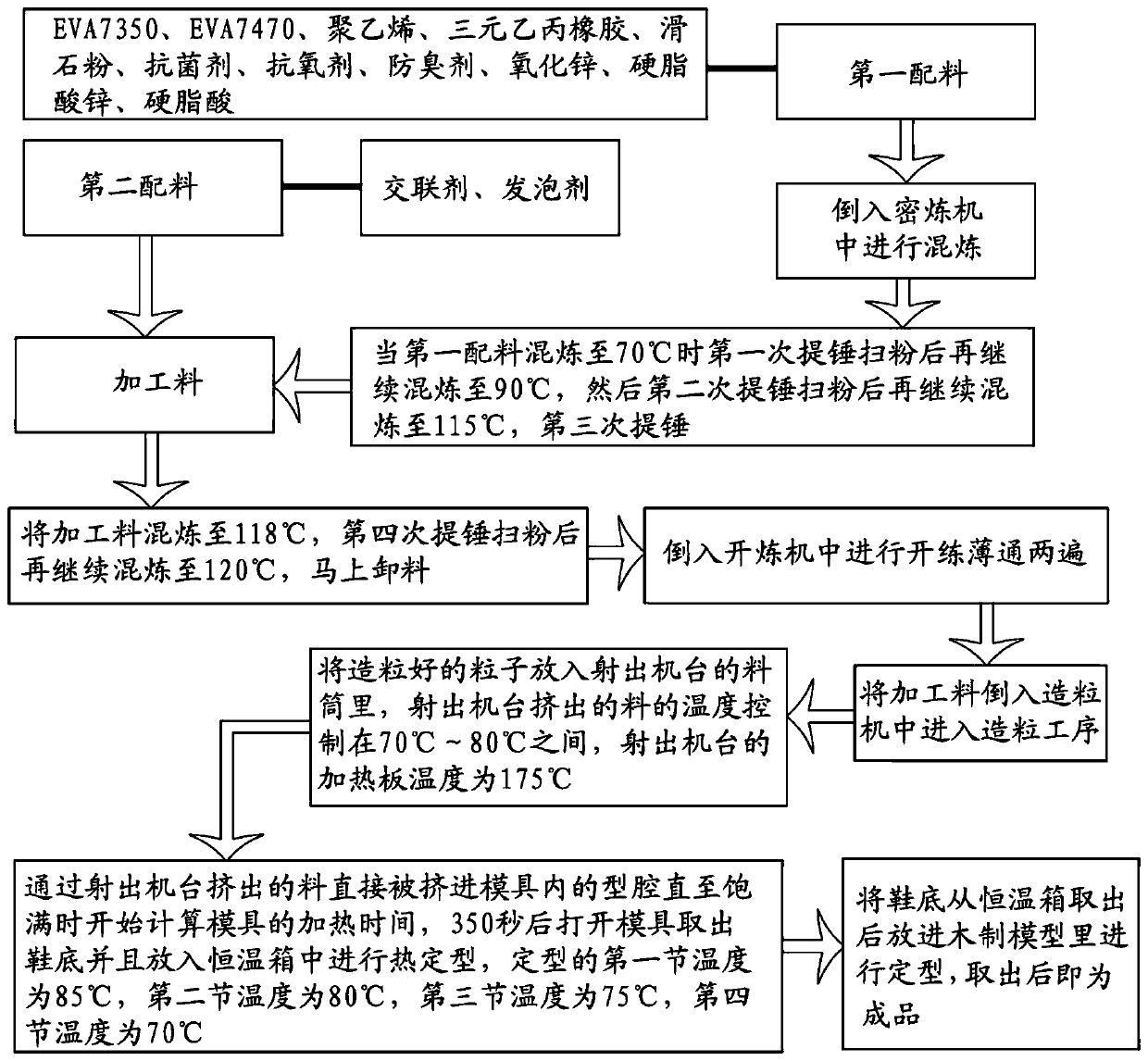

[0025] Such as figure 1 Shown, a kind of processing method of deodorant sole, this processing method specifically comprises the following steps:

[0026] Step 1, weigh EVA7350, EVA7470, polyethylene, EPDM rubber, talcum powder, antibacterial agent, antioxidant, deodorant, zinc oxide, zinc stearate, stearic acid and pour them together to combine forming a first ingredient;

[0027] In step 2, the cross-linking agent and foaming agent are weighed and poured together to form the second batch;

[0028] Step 3, pouring the first ingredient into the internal mixer for mixing;

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com